Automobile cable harness protection sleeve

A technology for automotive wiring harnesses and protective sleeves, applied in the direction of electrical components, etc., can solve problems such as complicated operation, unfavorable door modular assembly and maintenance, and inconvenient disassembly, so as to simplify assembly steps, facilitate modular assembly and later maintenance, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

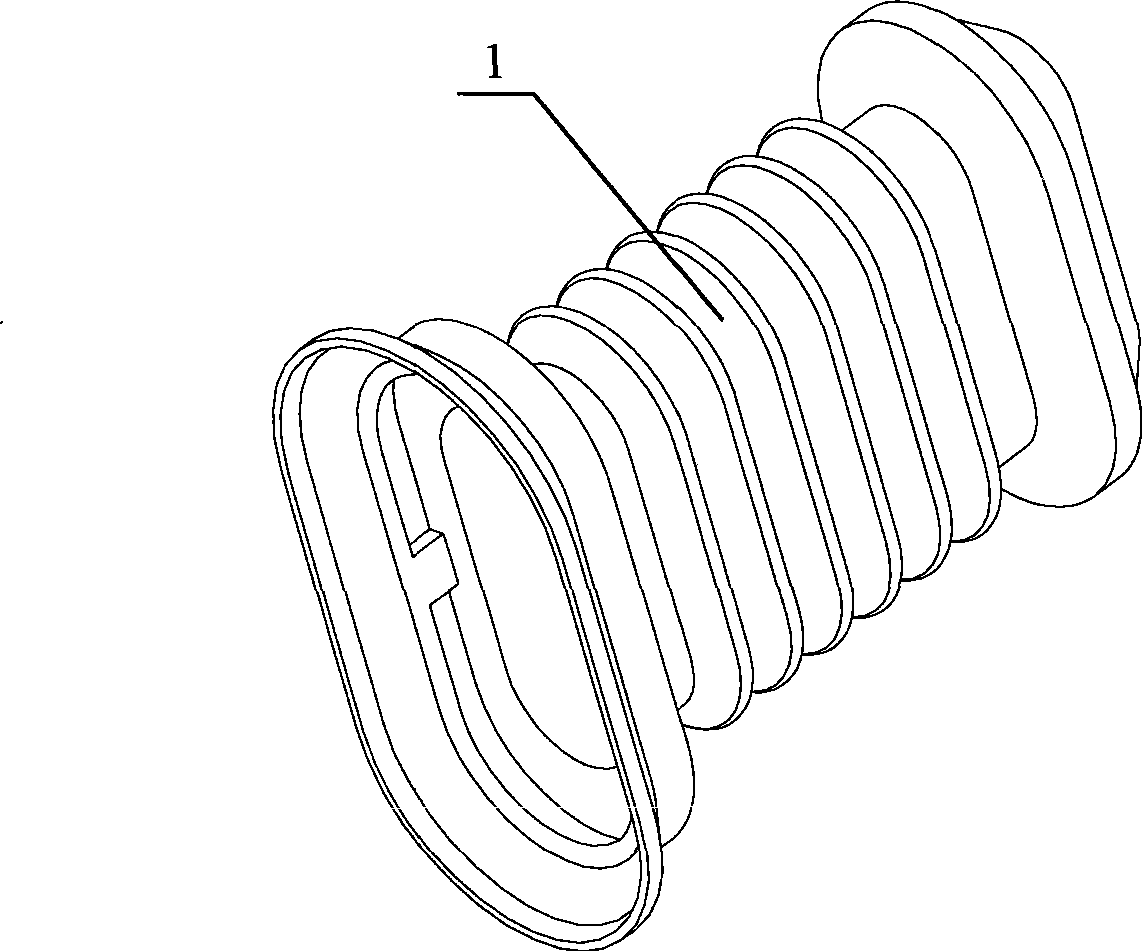

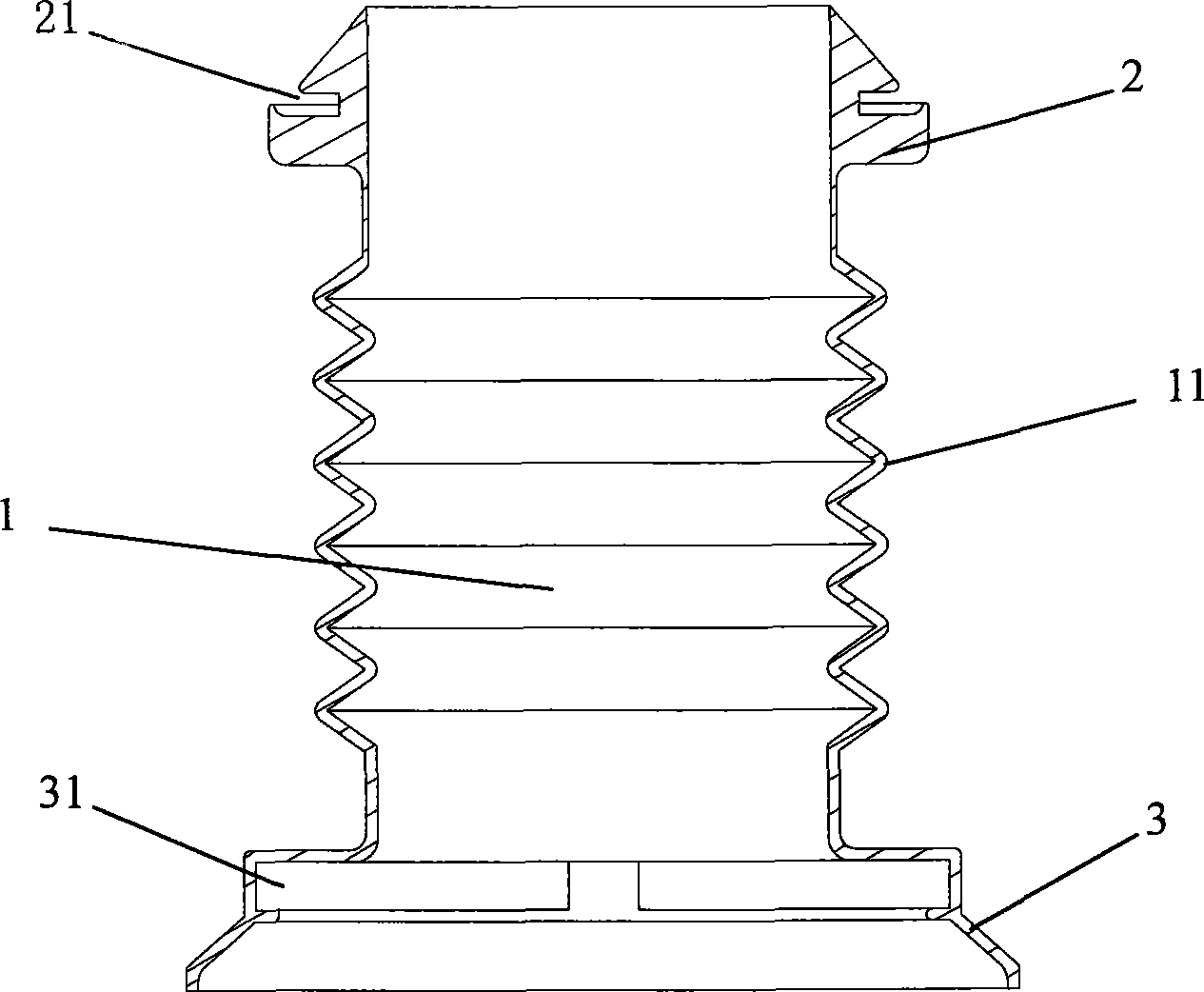

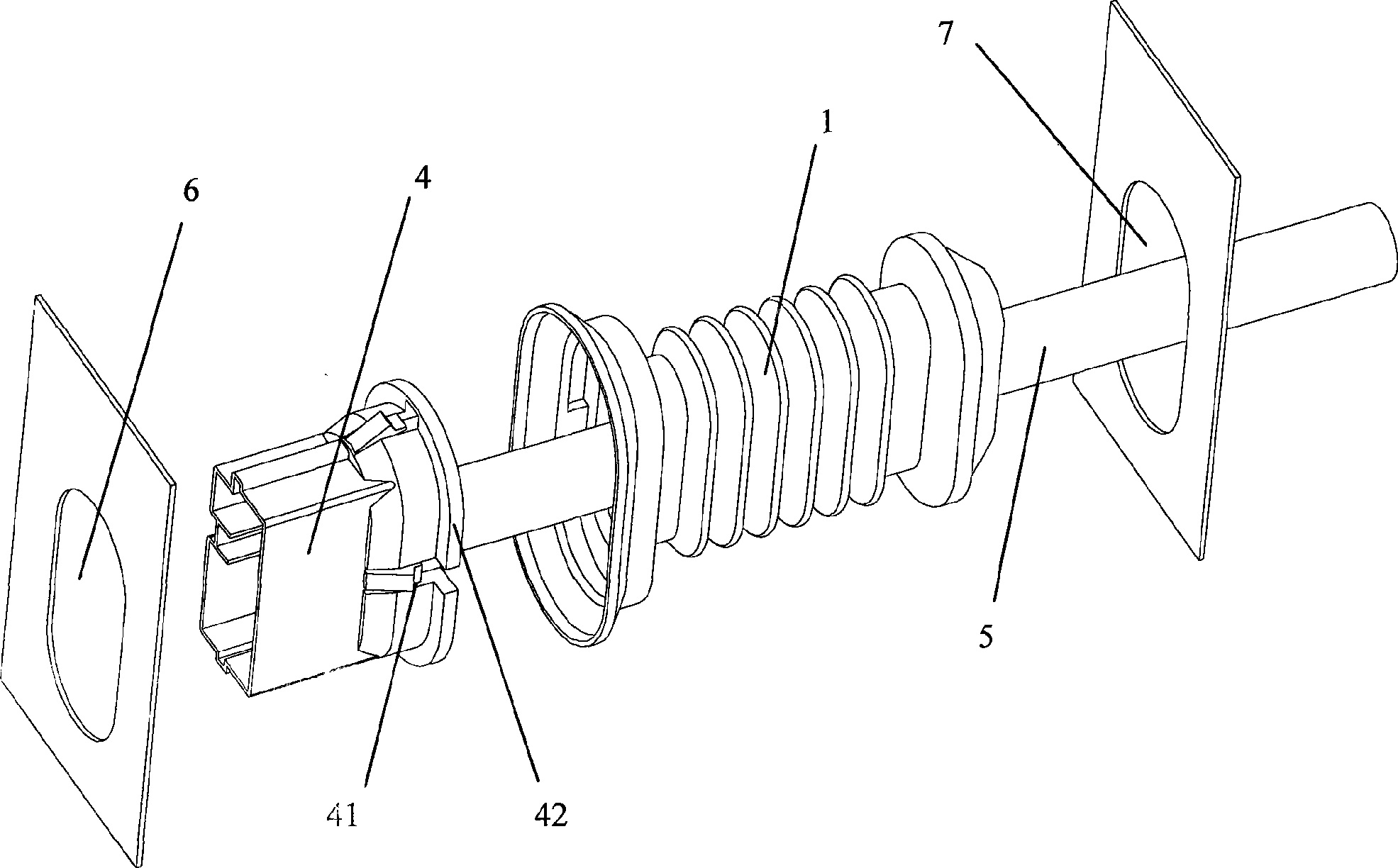

[0019] Such as figure 1 , 2 As shown, the automotive wiring harness protective cover of this embodiment includes a hollow tubular main body 1, the two ends of the main body 1 have tubular fixing parts 2 and 3, the main body 1 and the fixing parts 2 and 3 are integrated, and the tube of the fixing part 2 An annular groove 21 is arranged on the outer surface of the body, and an annular groove 31 is arranged on the inner surface of the tube of the fixing member 3 . The width of the annular grooves 21 and 31 is slightly wider than the thickness of the door and the body sheet metal.

[0020] The fixing part 3 is a trumpet-shaped structure expanding outwards, and the annular groove 31 is arranged at the connection between the fixing part 3 and the main body 1 . The outer surface of the tube of the fixing member 2 gradually shrinks from the inside to the outside to form a tapered slope, and the annular groove 21 is provided at a position where the fixing member 2 is close to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com