Adjustable width arc-shaped large steel mold

An arc-shaped and adjustable technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of wasting time and financial resources, poor structural adaptability, and the formwork shape can only be designed in a fixed form, etc. problems, to achieve the effect of convenient construction and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The structure of the present invention will be described in further detail below in conjunction with the drawings and embodiments.

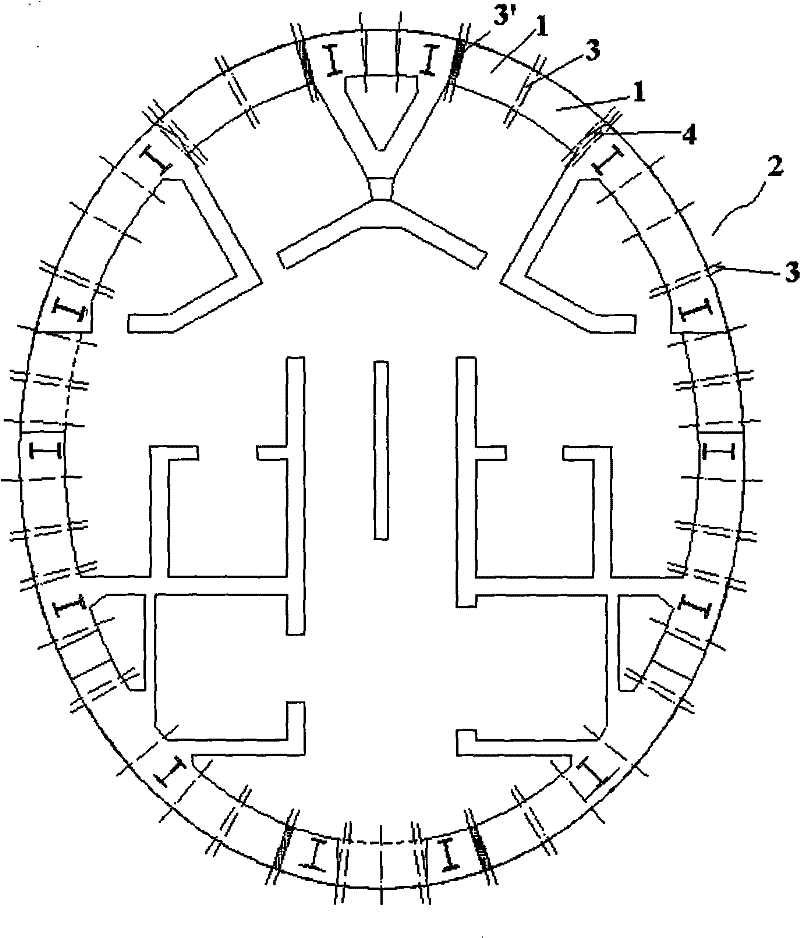

[0017] Such as figure 1 As shown, the present invention can adjust the width type arc-shaped large steel mold, which is in the shape of an arc as a whole, including several arc-shaped steel mold segments 1, and the arc-shaped steel mold segments 1 are connected to each other along the width direction to form The large arc-shaped steel mold 2 is partially provided with drawers 3 between two adjacent steel mold segments, and the drawers are uniformly arranged between two adjacent steel mold segments.

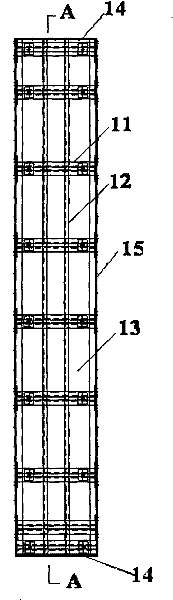

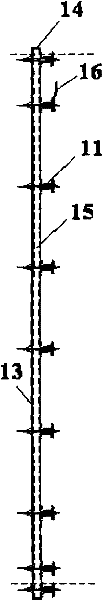

[0018] Such as Figure 2~4 As shown, the arc-shaped steel mold section includes horizontal purlins 11, vertical ribs 12, arc-shaped panels 13, longitudinal edge bands 14 and transverse edge bands 15, and the horizontal purlins 11 and vertical The rib 12 is fixed behind the arc-shaped panel 13, the longitudinal edge sealing plate 14 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com