Construction method of returning device of mechanical construction pump room equipment in tunnel

A construction method and technology in tunnels, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve problems such as mud film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

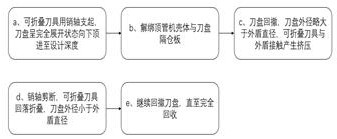

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

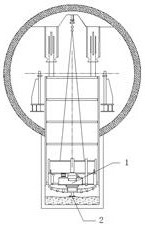

[0025] The structure for realizing the method includes devices such as a front shield, a folding cutter head, a drive, a hydraulic oil cylinder, and an extended seal. The hydraulic oil cylinder is connected with the front shield and the folding cutter head through the support on the flange, and is fixed through the pin connection. The extended seal is installed on the top flange surface of the inner shield of the pipe jacking machine, and is connected with the shield by bolts.

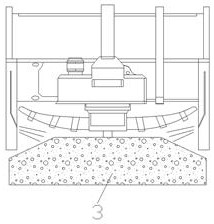

[0026] After the head of the pipe jacking machine is pushed downwards to the position, firstly, the muddy water in the muddy water bin is replaced by the Hengshim mud, and the muddy film is formed by compressing air. Secondly, remove the mud inlet and discharge pipelines while keeping the pressure, connect the concrete pumping pipeline through the central pump pipe interface,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com