Block pressure detection and processing equipment and method for injection pump

A technology of processing device and syringe pump, applied in measuring device, measuring fluid pressure, force/torque/work measuring instrument, etc., can solve problems such as danger, syringe pump falling off, separation, etc., to achieve good stability, improve performance, guarantee The effect of infusion safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

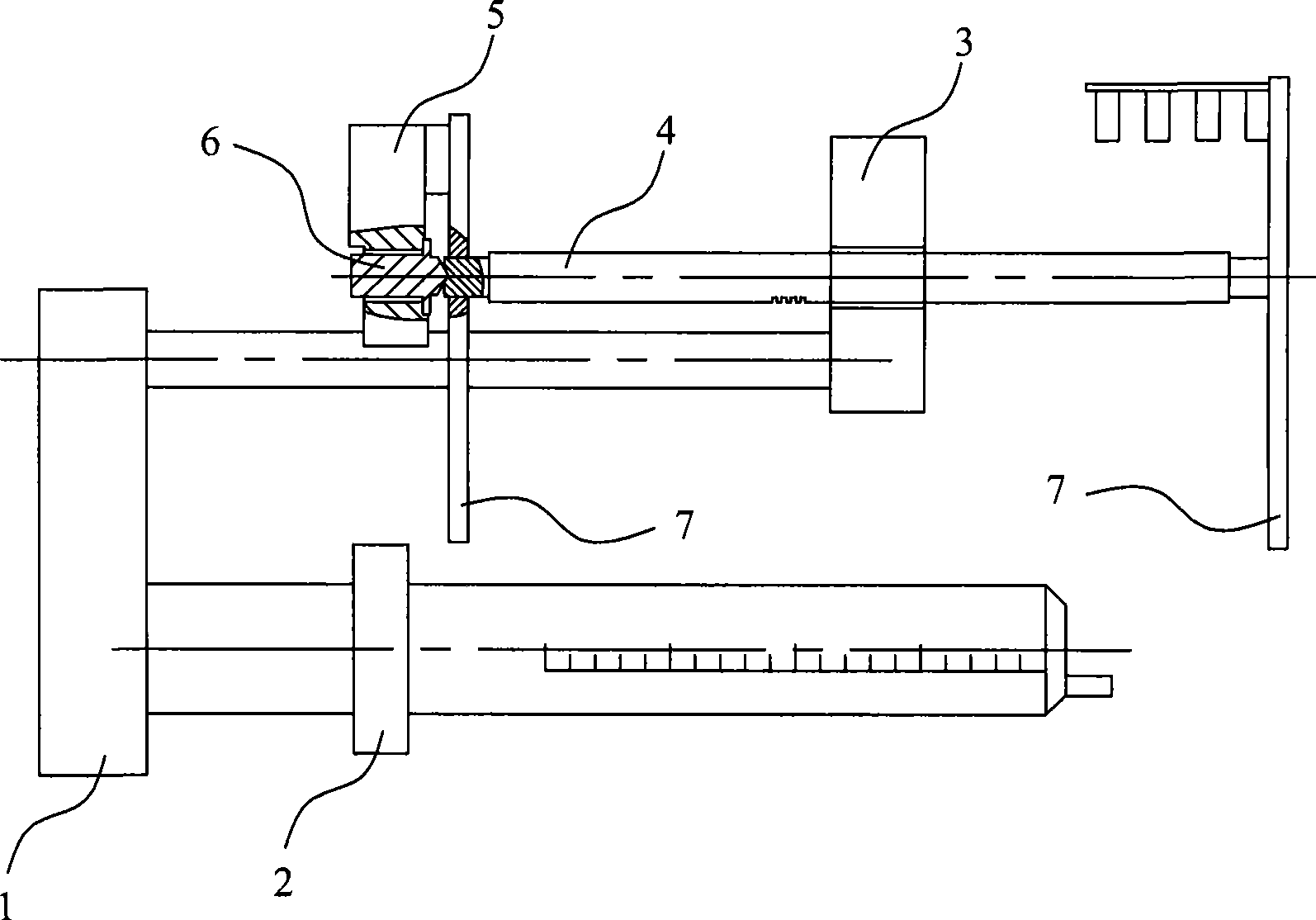

[0021] figure 1 It shows the structure of the injection pump blockage pressure detection and processing device of the present invention, including: a machine base 7, a screw 4, a pressure sensor 5, and a force transmission element 6, wherein the screw 4 communicates with the injection pump through the nut 3 arranged on it. The injection head 1 of the pump is fixedly connected. from figure 1 It can be seen from the figure that the force transmission element 6 is arranged to form a cylindrical structure with a shaft hole tightly fitted with the pressure sensor 5 fixed on the machine base 7, and its first end is a conical or truncated cone preloaded on the end of the screw 4. Shaped protrusions, so as to maintain point fit or surface fit with the lead screw 4 all the time. Both ends of the lead screw 4 are supported on the base 7 through bearings (not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com