Optical disk conveying device

A technology for transporting devices and optical discs, which is applied in the direction of recording information storage, instruments, etc., can solve problems such as inapplicability and scratches on the disc surface, and achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

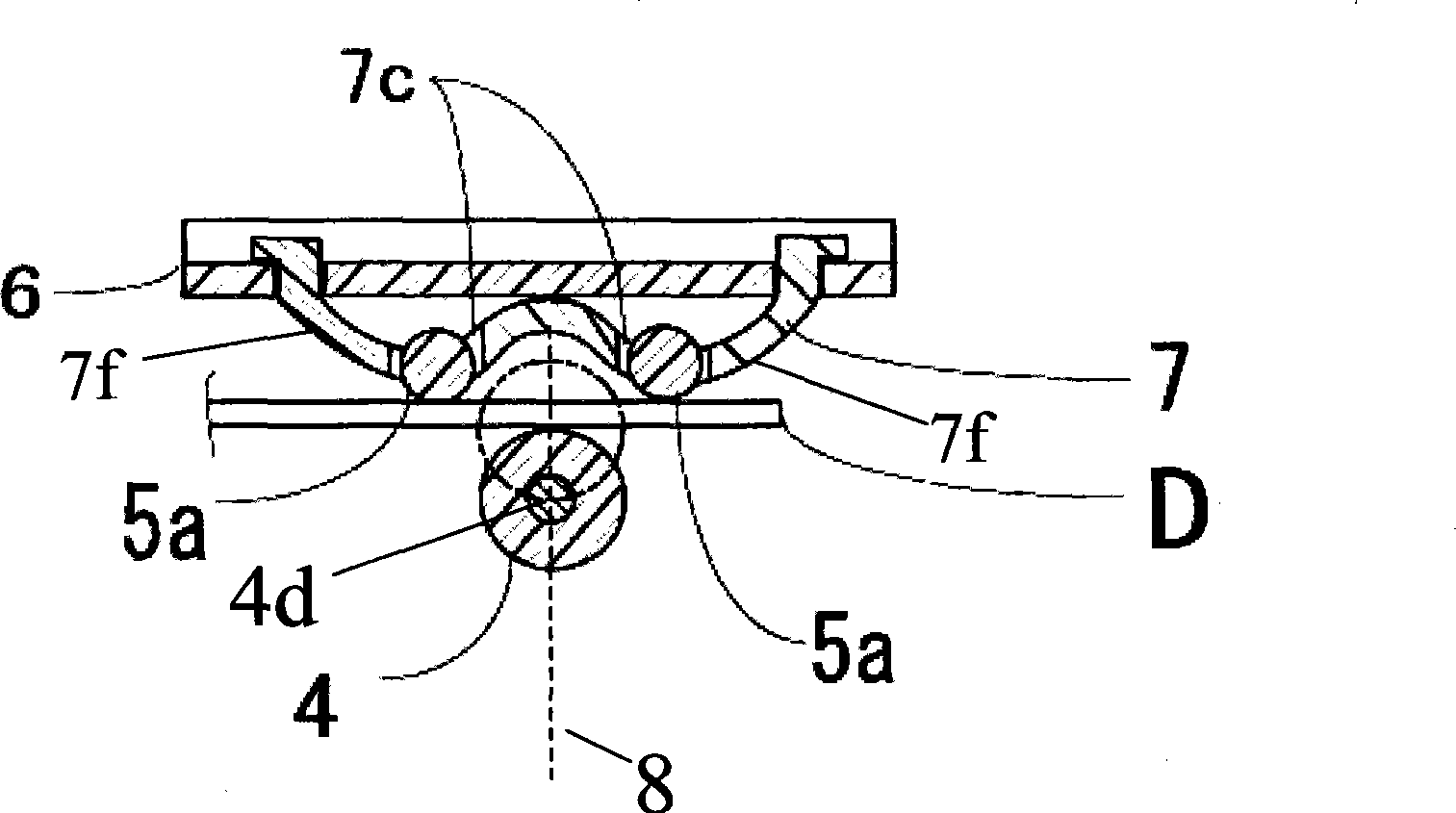

[0014] In the present invention, a double-cone structure of the transfer roller is adopted, and the diameter of the roller body of the transfer roller is gradually reduced from both ends to the middle. At a position opposite to each cone of the transfer roller, there is provided a follower contacting the outer circumference of the optical disc. And ensure that the driven roller can rotate freely. A further description will be given below in conjunction with the drawings.

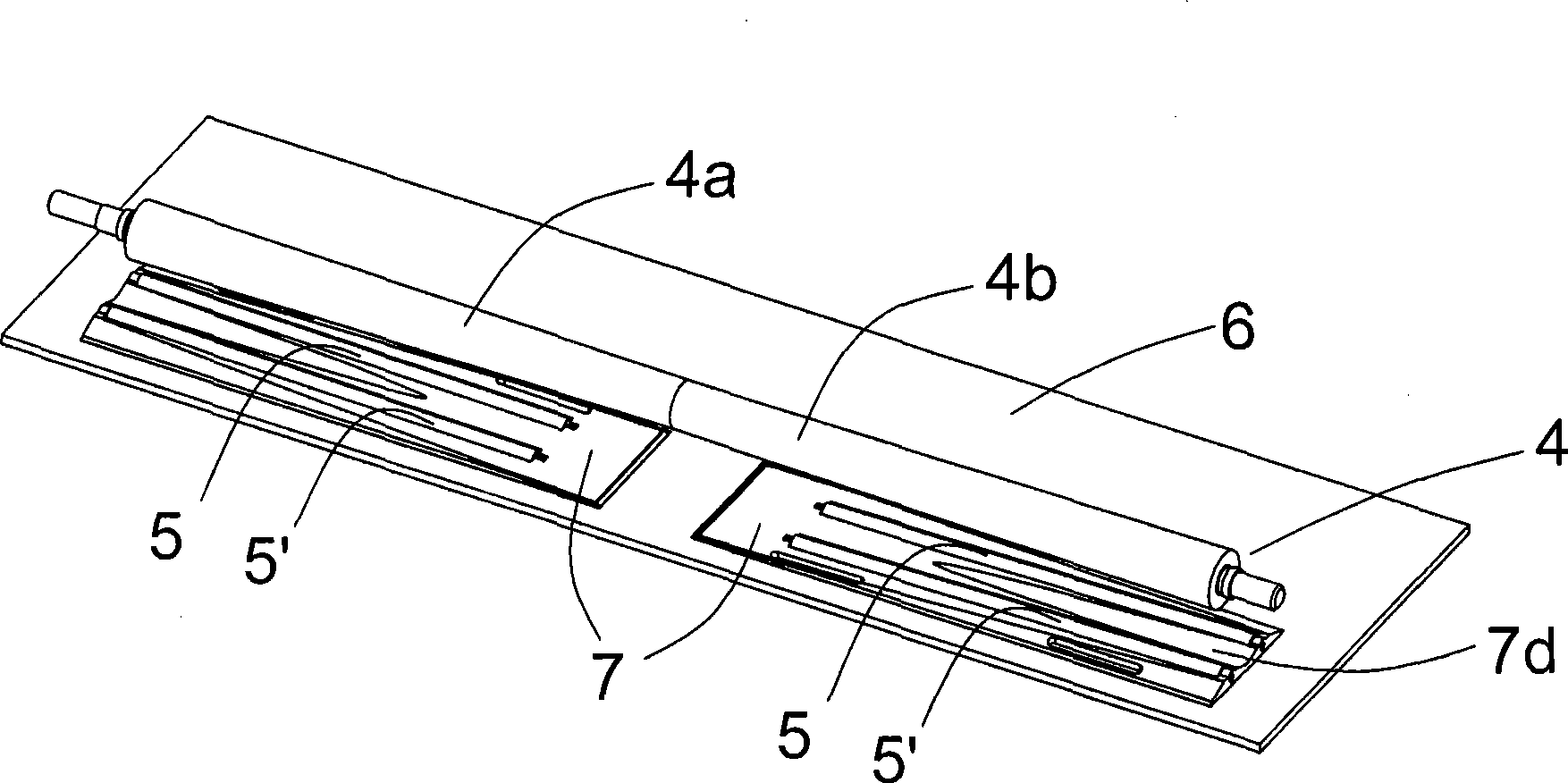

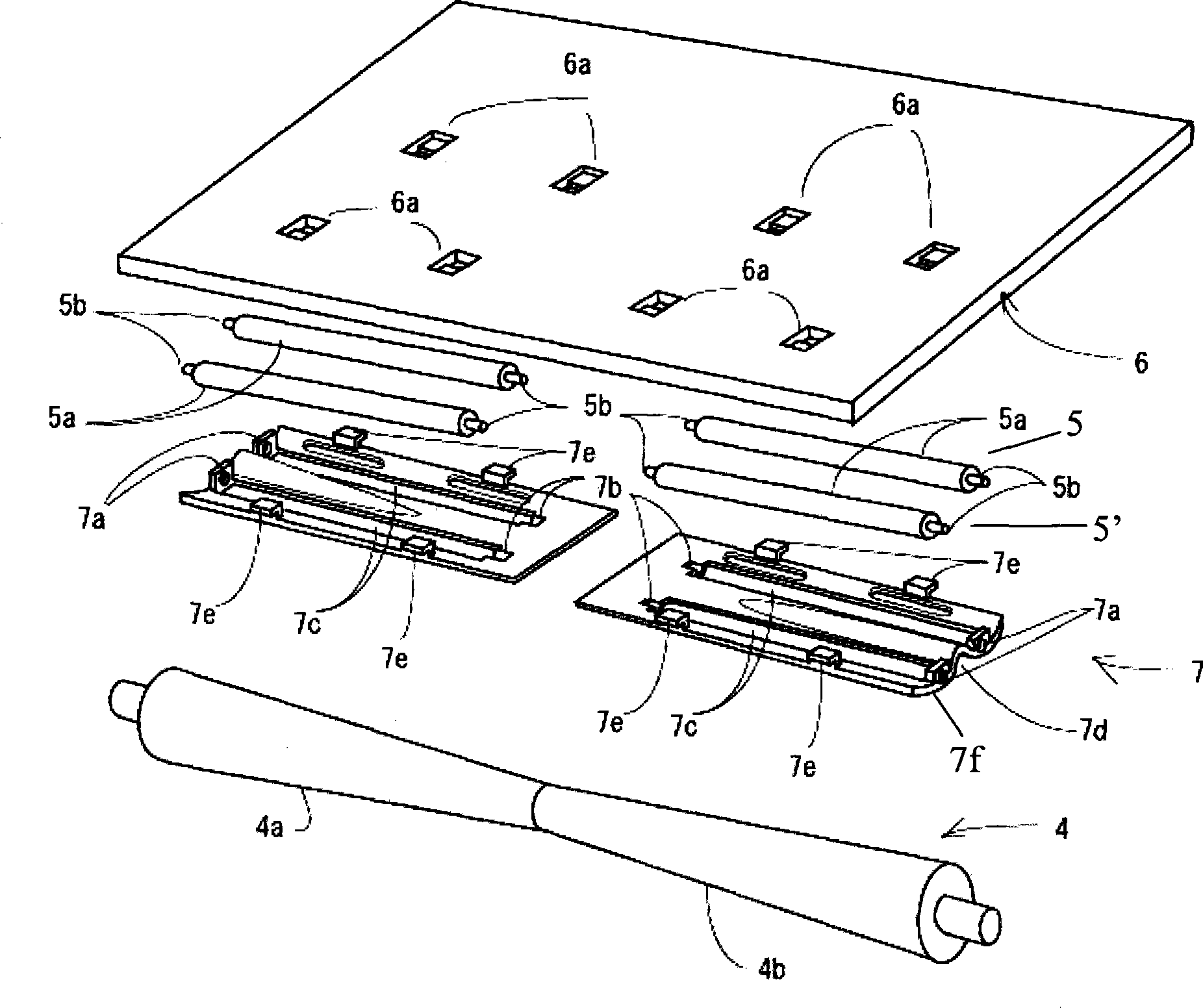

[0015] Refer to Figure 1-3 , The present optical disc conveying device includes a conveying roller 4, a guide member 7 located above the conveying roller 4, and an elastic member 10 for pressing the conveying roller 4 to the guide member 7 (see Figure 5 ), and the motor M used to drive the transfer roller 4 to rotate (see Figure 4 ), the roller body of the conveying roller 4 is a double cone structure with a diameter gradually reduced from both ends to the middle, and two rotatable positions are installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com