A shearer loader for underground mining comprising a spray system

A mining machine, drum-type technology, applied in the field of drum-type mining machines with sprinkler systems for underground mining, can solve the problems of increased risk of dust formation and ignition, power increase, etc., to achieve the goal of optimizing and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

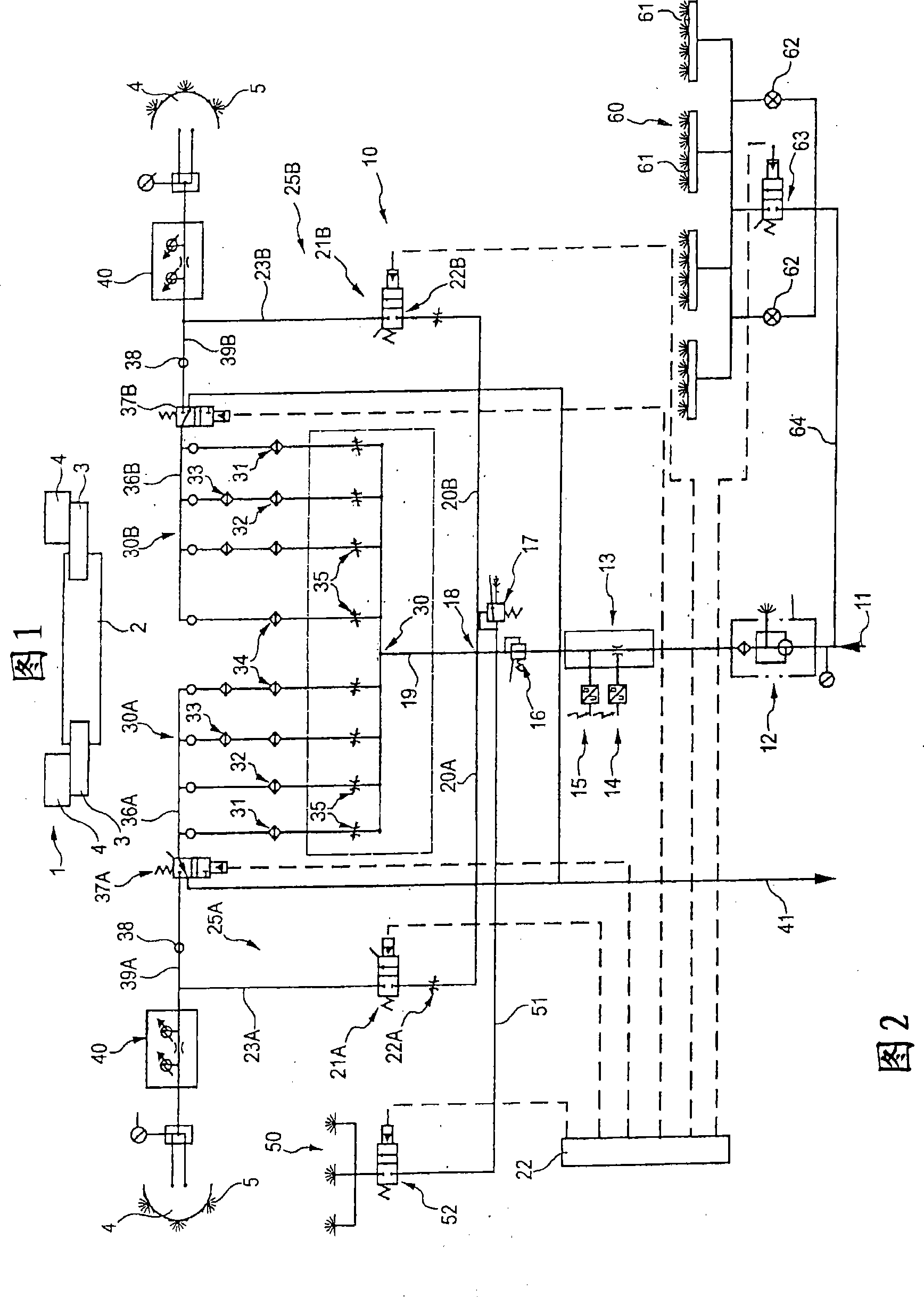

[0017] In FIG. 1, a very schematically simplified illustration of a drum mining machine 1, in particular for mining coal in underground mining, has a drum mining machine body 2, which It is possible to travel on a transmission layer (triebstock) which is arranged parallel to the conveyor (not shown) in the working plane. Mounted on the main body 2 of the drum mining machine are support arms 3 for each of the two directions of travel of the drum mining machine 1 , on which a cutting drum 4 is rotatably supported for each direction of travel, The cutting drum is equipped with a plurality of picks (not shown) as machining tools, with which the ore to be excavated, in particular such as coal, is excavated on the excavation face. A water circuit system not shown in FIG. 1 is integrated in the support arm 3 and in the cutting drum 4 in the main body 2 of the drum mining machine. The drive system of each individual device and the cooling water circulation loop of the motor and a spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com