Tractor and printer with the tractor

A technology of tractor and main body, applied in the field of printers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

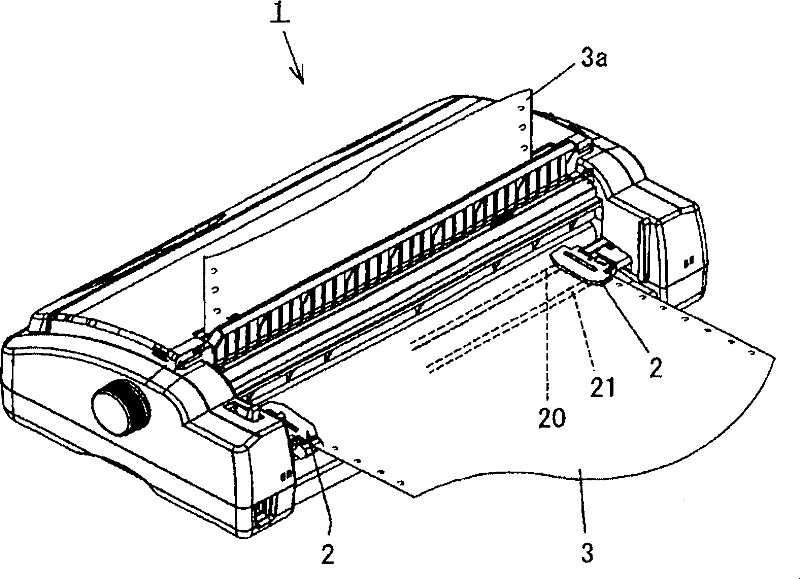

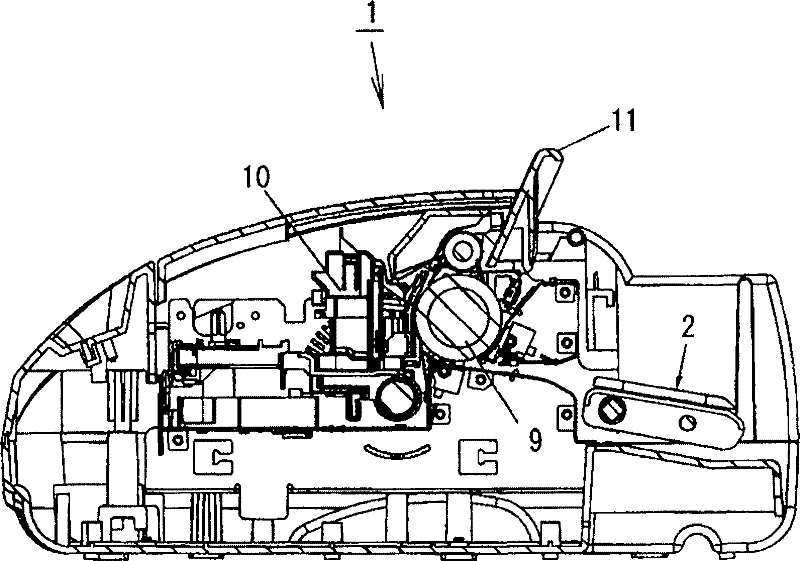

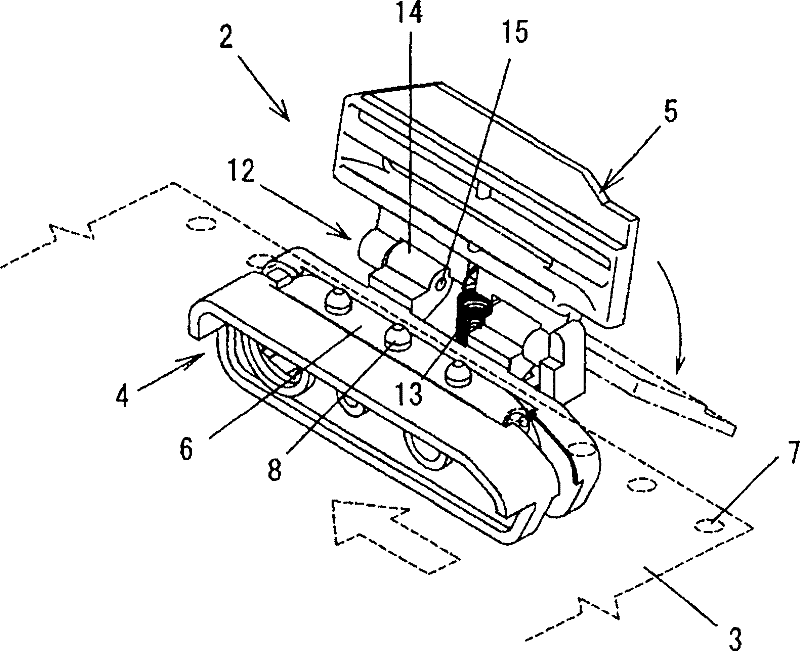

[0034] The retractor 2 has a main body 4 , a cover 5 and a tension coil spring 13 . The main body 4 is made of hard synthetic resin, such as Figure 6 As shown, there is a supply figure 1The drive shaft penetration hole 18 through which the drive shaft 20 is inserted is formed behind (on the upstream side in the paper conveyance direction A) for a feeder. figure 1 The guide shaft penetration hole 19 through which the guide shaft 21 is shown penetrates.

[0035] The drive shaft 20 and the guide shaft 21 are erected on the side parallel to the left-right direction (direction perpendicular to the conveyance direction of the continuous paper 3). figure 1 In the printer 1, these shafts 20, 21 pass through the through holes 18, 19 of the tractor 2, whereby the tractor 2 is supported by these shafts 20, 21.

[0036] The cross section of the drive shaft 20 penetrating the drive shaft through hole 18 is substantially rectangular, and the drive shaft 20 penetrates a drive sprocket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com