Pressure vessel arrangement

A pressure vessel and differential pressure technology, applied in the field of pressure vessel devices, can solve the problem of unutilized installation space and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

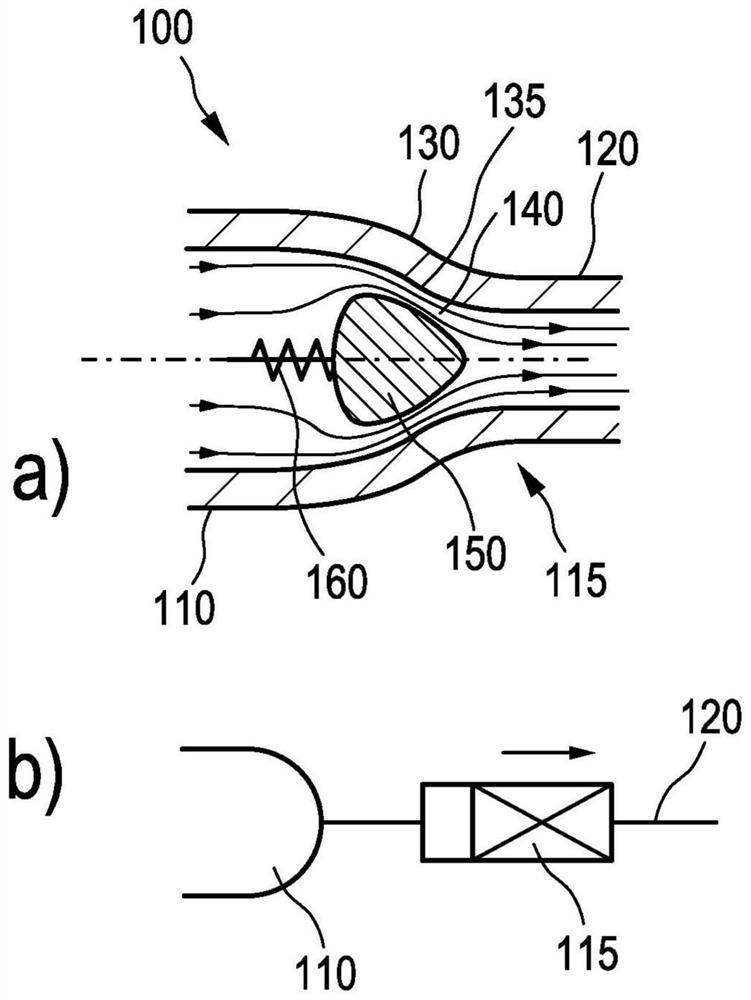

[0040] figure 1 a shows a section of the pressure vessel arrangement 100 , more precisely the transition between a pressure vessel 110 and the connecting line 120 connected thereto. A narrowing 130 is formed between the pressure vessel 110 and the connecting line 120 . A safety valve 115 is formed in the taper, which will be described in more detail below.

[0041] The safety valve 115 has a valve body 150 . The valve body is fixed on a pretensioning device in the form of a spring 160 which allows the valve body 150 to figure 1 In the illustration of a, it is moved in the horizontal direction and is here pretensioned to the left away from the narrowing 130 . In this case, valve body 150 is surrounded by a fluid flow, which is indicated by arrows. The fluid flow is thus in figure 1 Flow from left to right in the illustration of a.

[0042] Between the valve body 150 and the narrowing 130 a compression 140 of the flow lines takes place, which leads to a negative pressure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com