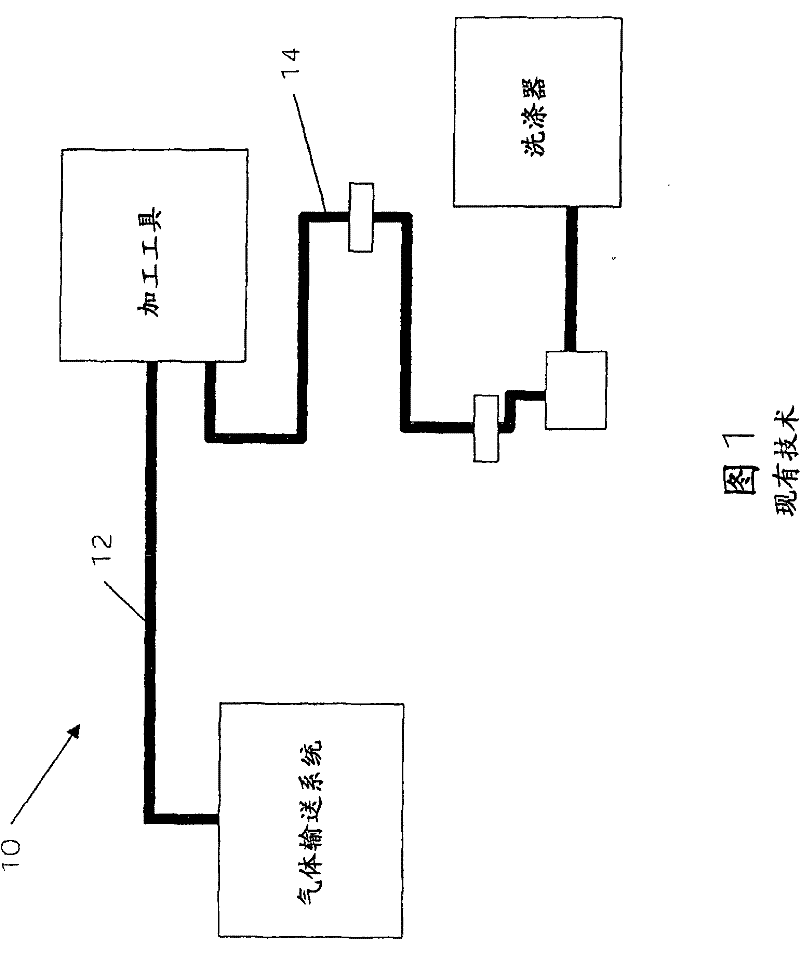

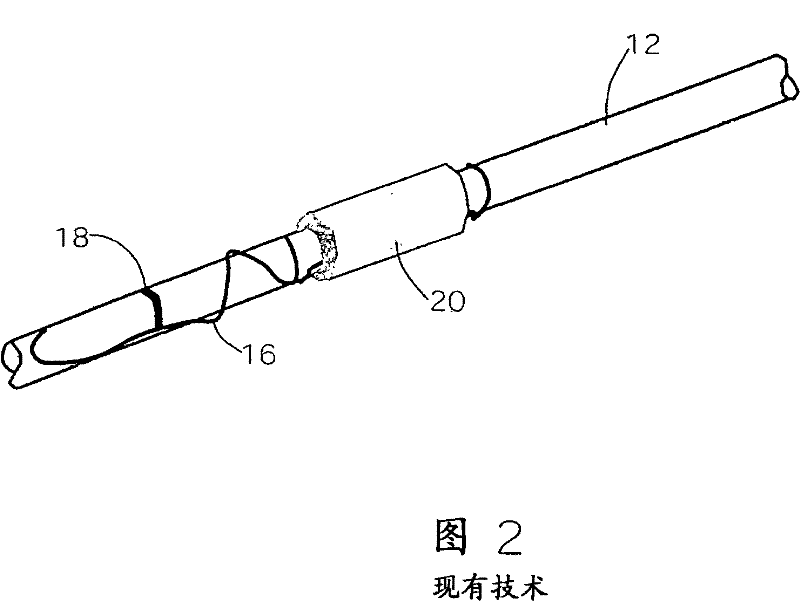

Modular heater systems

A technology of heating elements and heat joints, applied in the shape of heating elements, pipeline heating/cooling, electric heating devices, etc., can solve the problems of increasing storage space, manufacturing costs and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

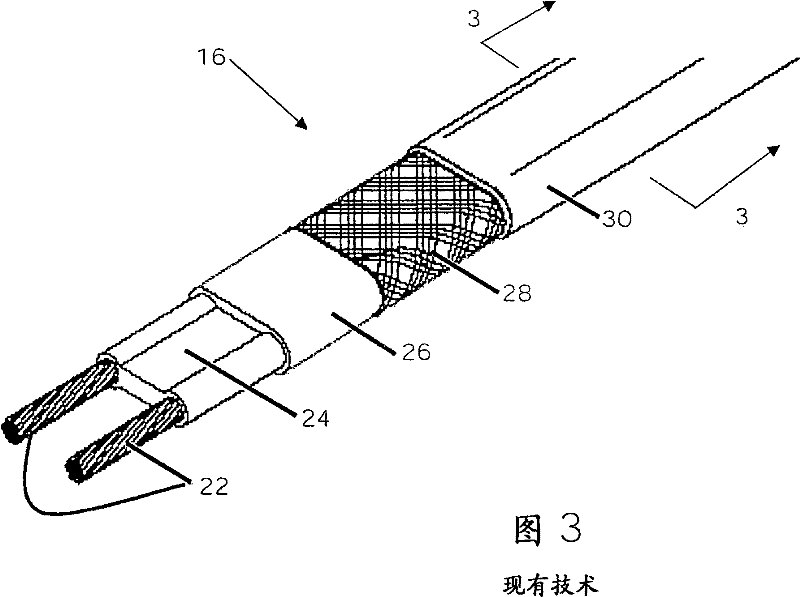

[0095] The following descriptions are merely exemplary in nature, and are not intended to limit the content, application occasions and usage methods of the present invention.

[0096] The structure of the heater according to the present invention will now be described in more detail. First, it should be understood that the term "conduit" as used throughout this specification includes, but is not limited to, pipes, pipes, and other closed or partially closed components for transporting fluid or other materials such as powder or slurry. Materials conveyed by conduits described herein include solids, liquids, and gases, and, by way of example, may include fluids conveyed in semiconductor processing equipment. The preferred embodiments described below with reference to such semiconductor processing apparatus are merely exemplary in nature and in no way limit the disclosure, application, and manner of use of the invention. Accordingly, the teachings of the present invention are no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com