Water jug

A kettle and kettle body technology, applied to drinking water vessels, travel or camping equipment, household appliances, etc., can solve the problems of inconvenient use, affecting drinking hygiene and safety, and the inability of the control valve 13 to seal the water outlet, so as to avoid pollution and ensure Effects of drinking hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

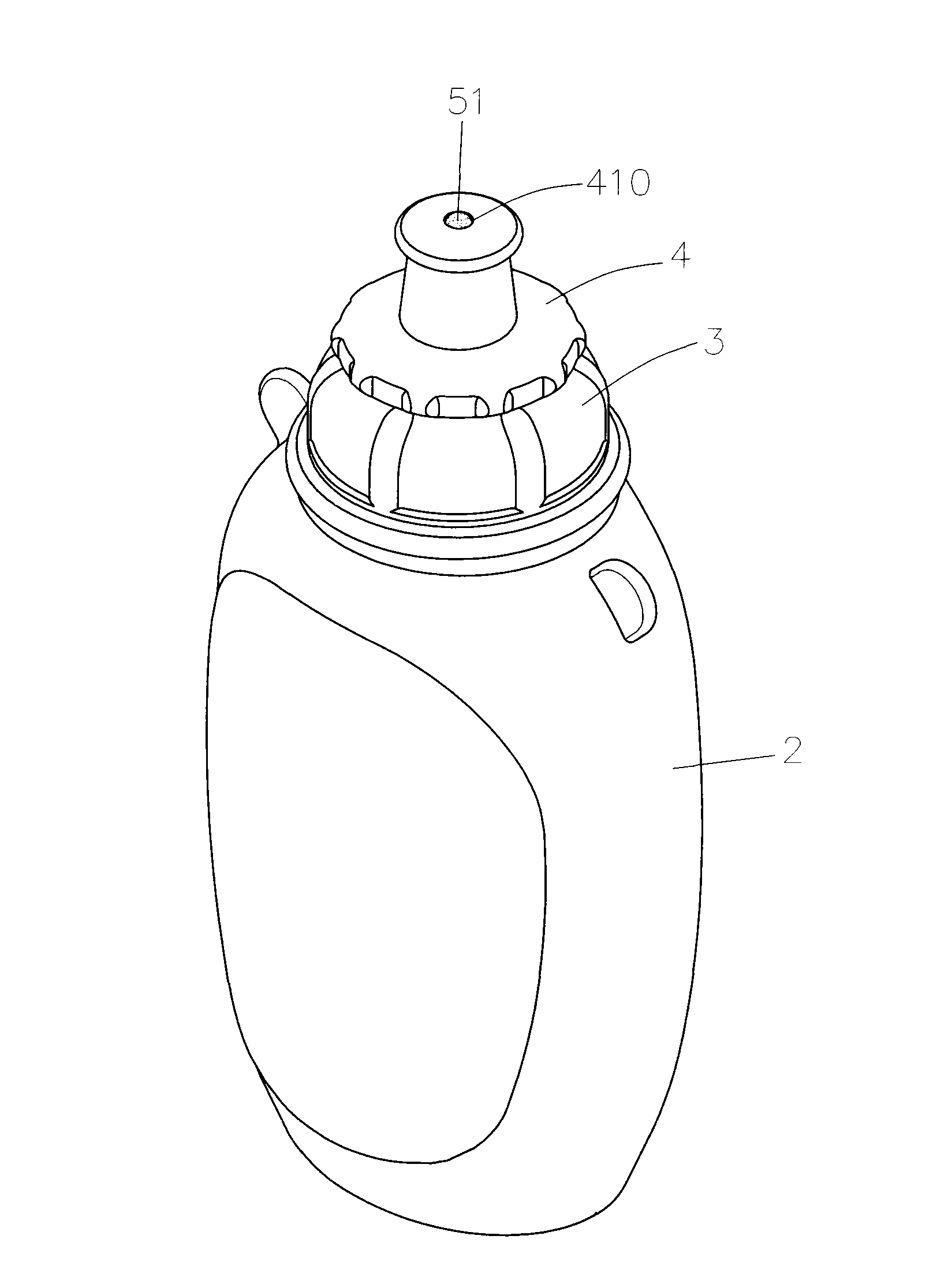

[0019] Relevant present invention is for reaching above-mentioned purpose of use and effect, the technical means that adopts, presents preferred feasible embodiment hereby, cooperates as shown in the drawing simultaneously, is described in detail as follows:

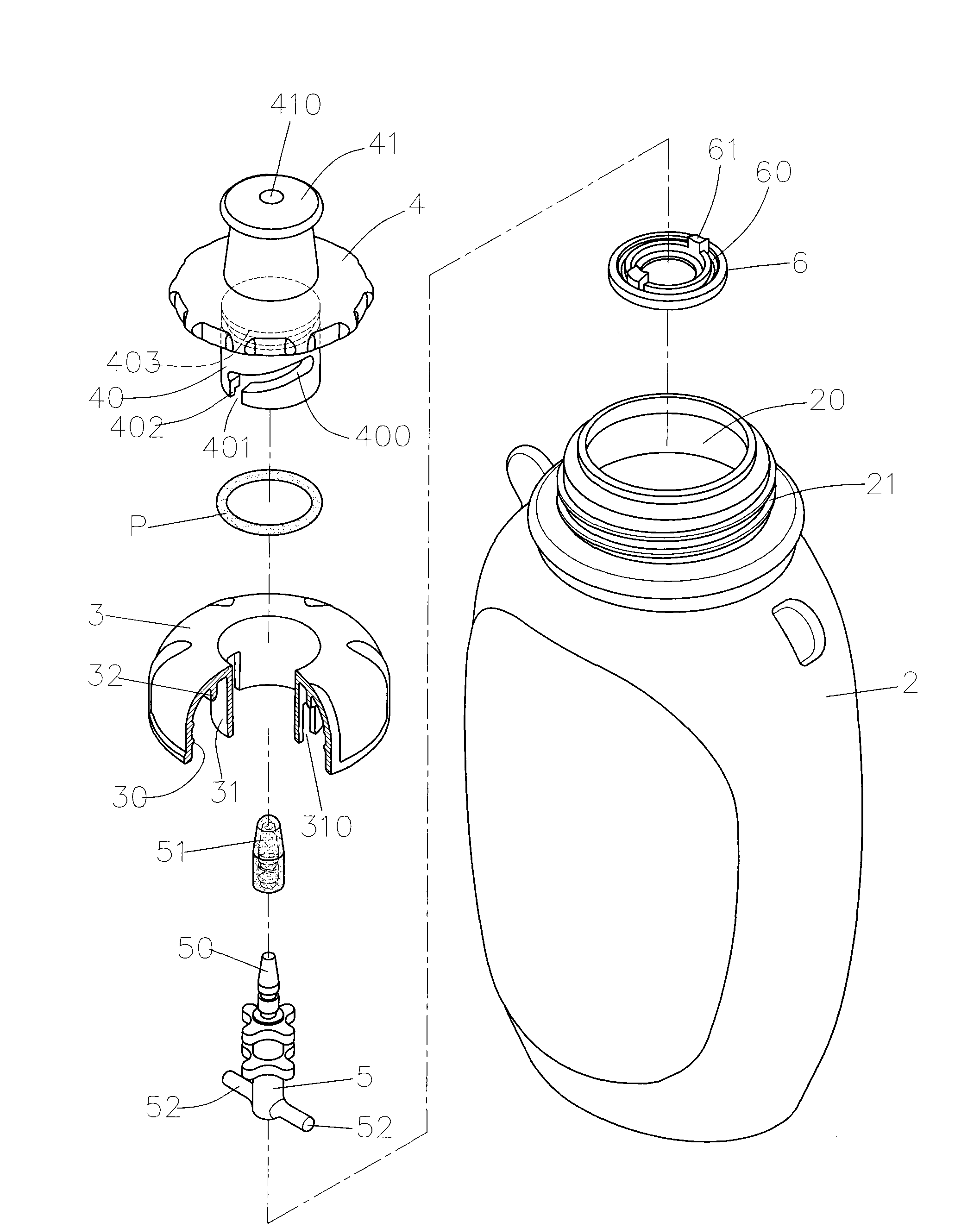

[0020] First, please refer to figure 2 As shown, it mainly has:

[0021] A pot body 2, a spout 20 is provided above the pot body 2, and a threaded joint 21 is provided outside the spout 20;

[0022] The kettle lid 3 is assembled on the spout 20 of the kettle body 2, and the joint portion 21 corresponding to the kettle body 2 is provided with a threaded joint portion 30, and the middle of the kettle lid 3 is provided with a hollow sleeve portion 31, which can be extended into the spout 20 of the kettle body 2, the opposite sides of the sleeve portion 31 are provided with notches 310, and in addition, a ring 32 is provided on the periphery of the sleeve portion 31 in the kettle lid 3, It can be used to block against the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap