Methane station for intensive gas supply

A biogas and gas storage tank technology, applied in the field of biogas, can solve the problems of large area, labor and materials, inconvenient refueling, etc., and achieve the effect of saving land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

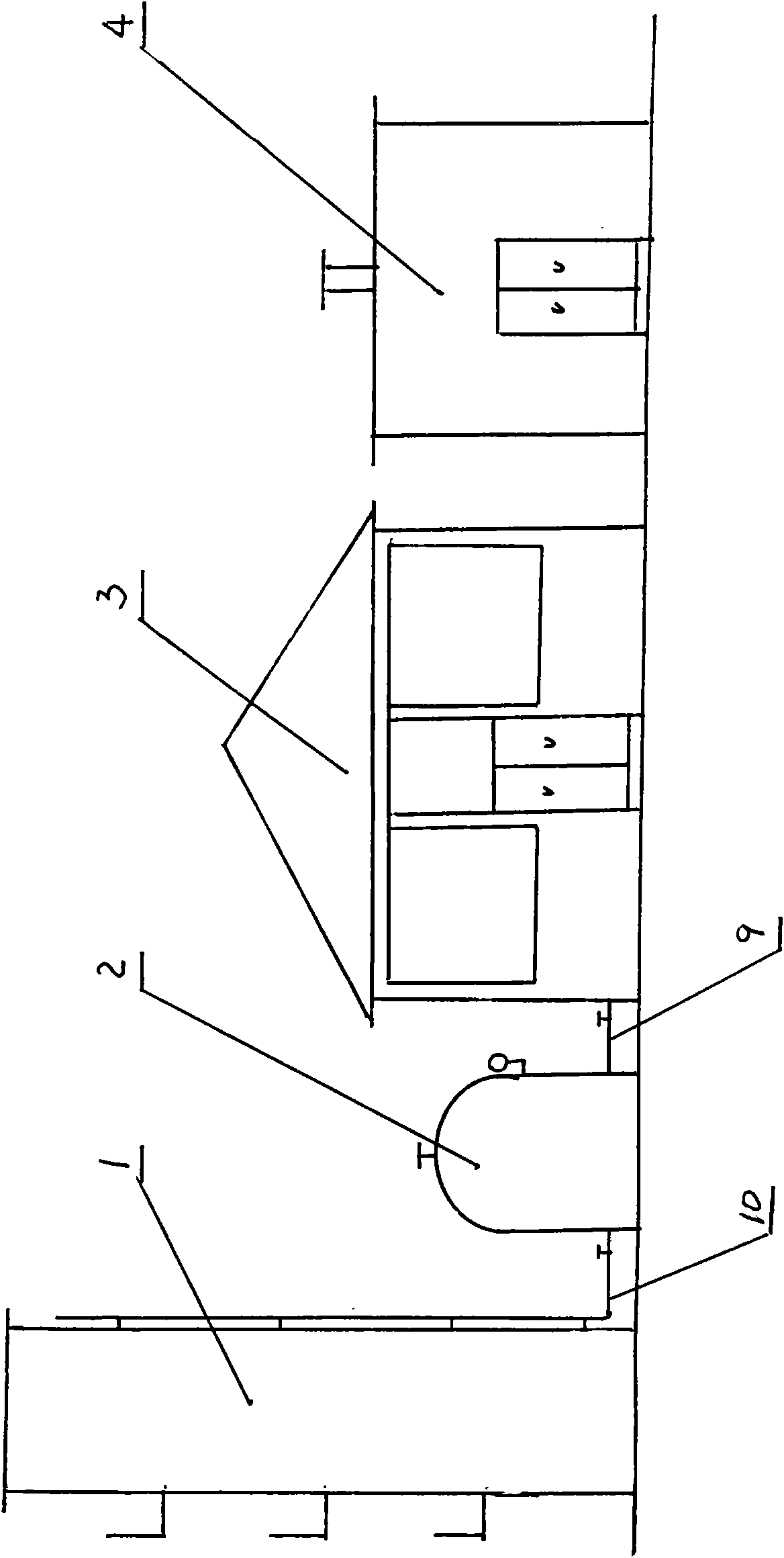

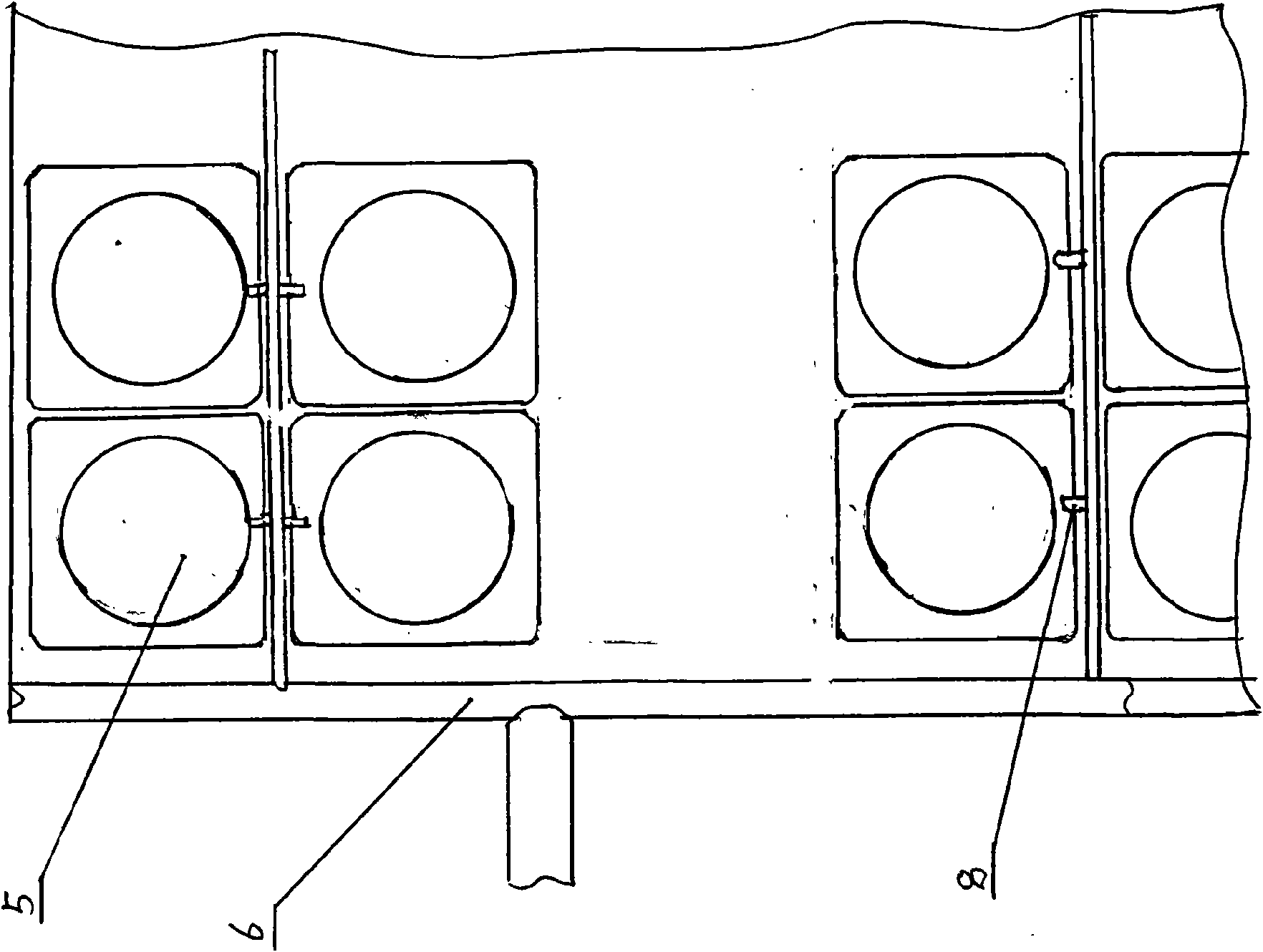

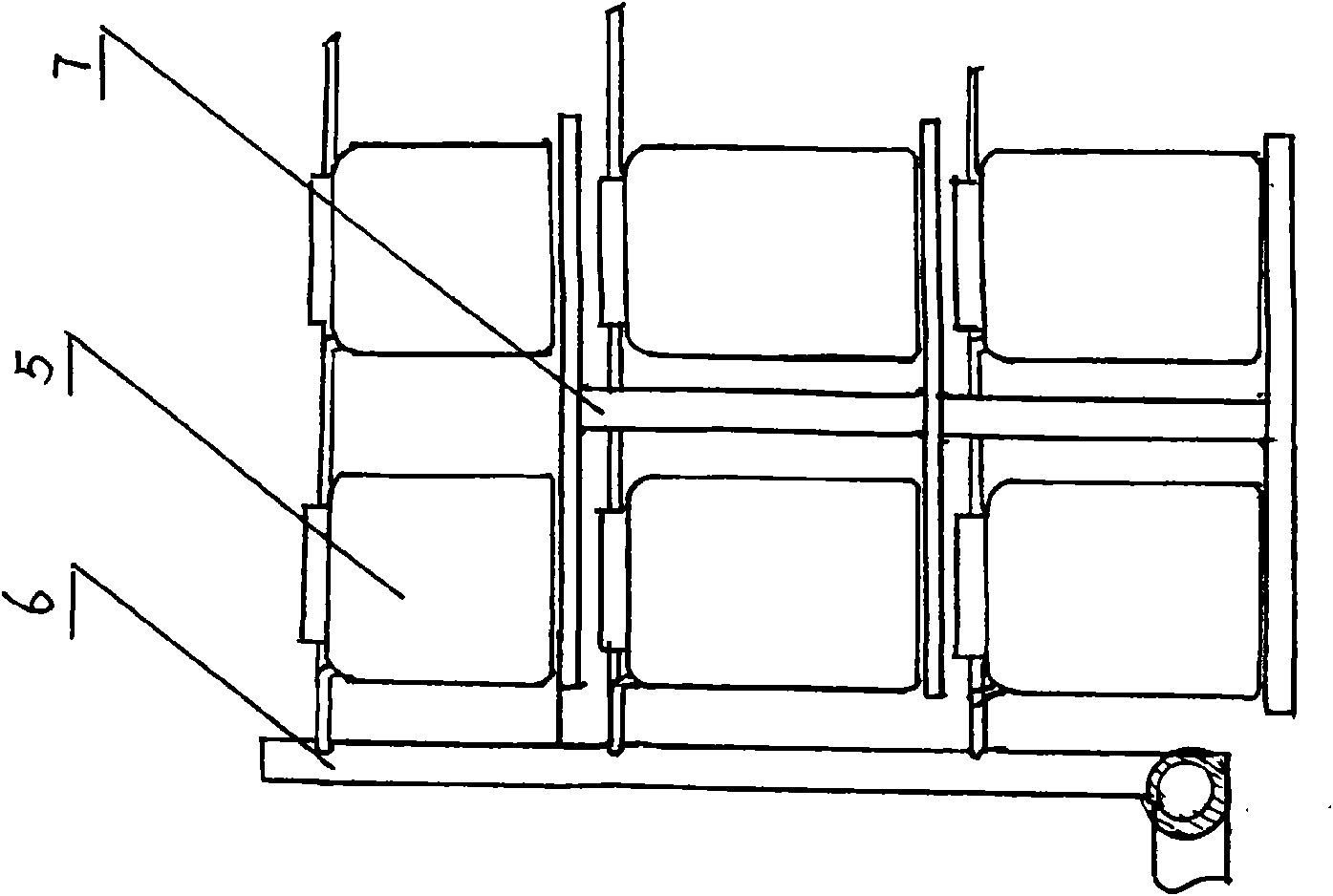

[0012] figure 1 , figure 2 , image 3 Shown is a schematic diagram of a centralized gas supply biogas station for 100 households. The specific embodiment will be described in detail according to the drawings.

[0013] 1. First of all, site selection: it is best to choose a place adjacent to the livestock breeding factory, so that manure can be used as biogas material, and then calculate the size of a solar greenhouse 3 and the storage warehouse according to the predetermined scale. 4. How big is the gas tank 2, how many biogas tanks 5, how big is the drying room, etc. Calculated by feeding 2-3 tons per household, it needs 40×40×40cm 3 (60 liters) of 50 barrels, 100 households need 5000 barrels. Calculated on three floors, the usable area is about 260m 2 , 300m plus pedestrian walkway 2 of greenhouses, each household uses 1m each time 3 Gas calculation, when 100 households use it at the same time, it takes 100m 3 gas, use 200m 3 2 gas tanks are sufficient.

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com