Method and apparatus of friction welding

A technology of friction welding and welding parts, which is applied in welding equipment, high-frequency current welding equipment, non-electric welding equipment, etc., and can solve problems such as ugly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

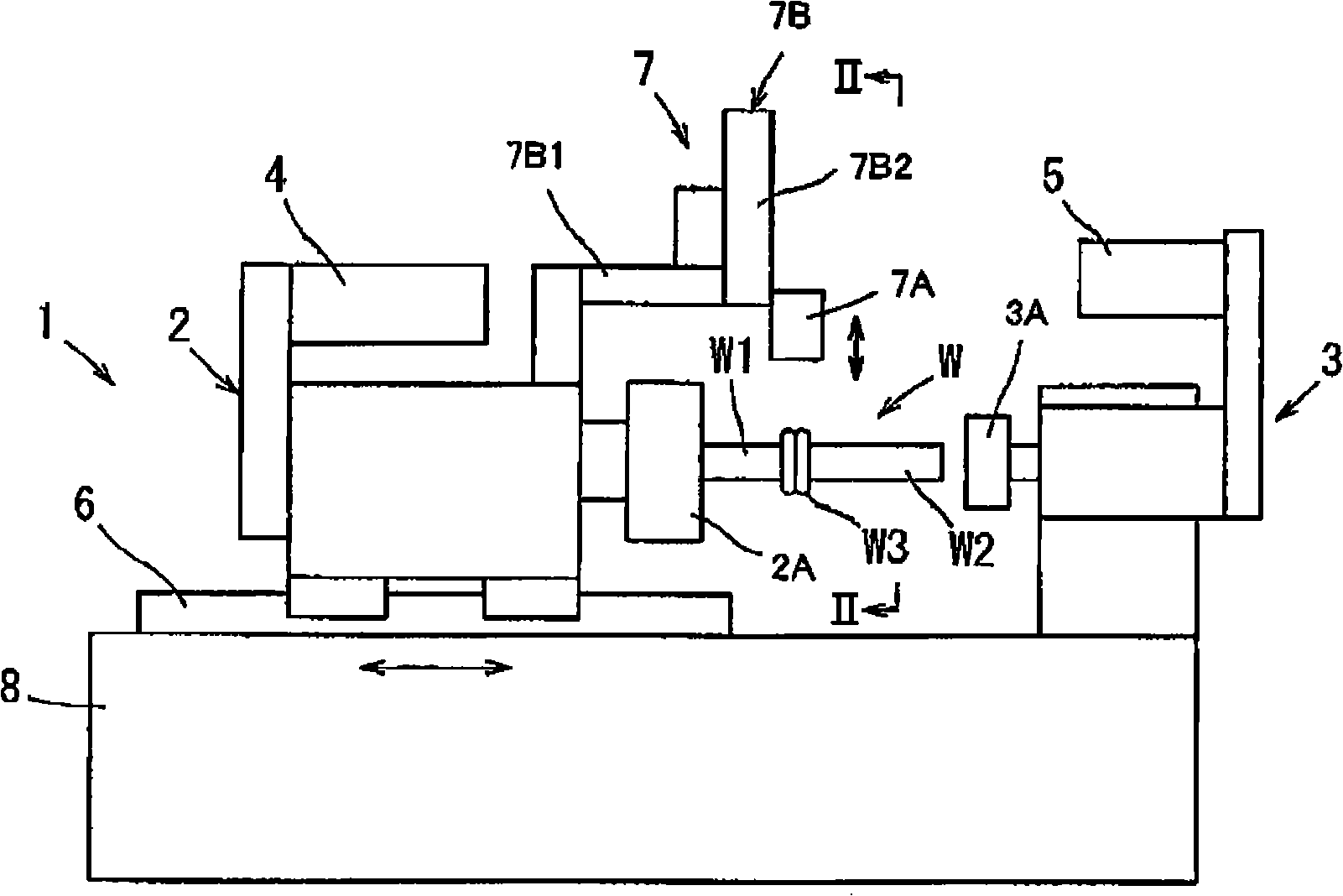

[0016] The following will refer to Figures 1 to 8 Embodiments of the present invention are described. refer to figure 1 , the friction welding device 1 includes a base 8 , a first holder 2 (spindle unit) and a second holder 3 . A guide 6 is installed at a position adjacent to the left end of the pedestal 8 . The first holder 2 is slidably installed with respect to the guide 6 and moved along the guide 6 by a thrust motor (not shown). The second holder 3 is immovably mounted on the pedestal 8 at its right end. The first holder 2 has a chuck 2A to detachably hold a round bar-shaped first workpiece W1. On the first holder 2 is mounted a motor 4 operable to rotate the chuck 2A around its axis. Also, the second holder 3 has a chuck 3A to detachably hold a round bar-shaped second workpiece W2. On the second holder 3 is mounted a motor 5 operable to rotate the chuck 3A around its axis.

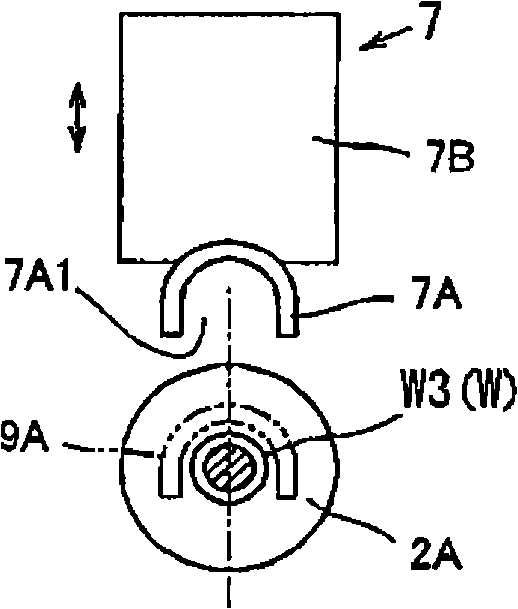

[0017] A high-frequency induction heater 7 is mounted on the first holder 2 to inductivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com