Fixing device and floor type lamp provided with same

A fixed device and floor-standing technology, which is applied to the parts of lighting devices, light source fixing, lighting devices, etc., can solve the problems of falling off lamp rods, unstable lamp rods, swaying and other problems, and achieve the effect of convenient installation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

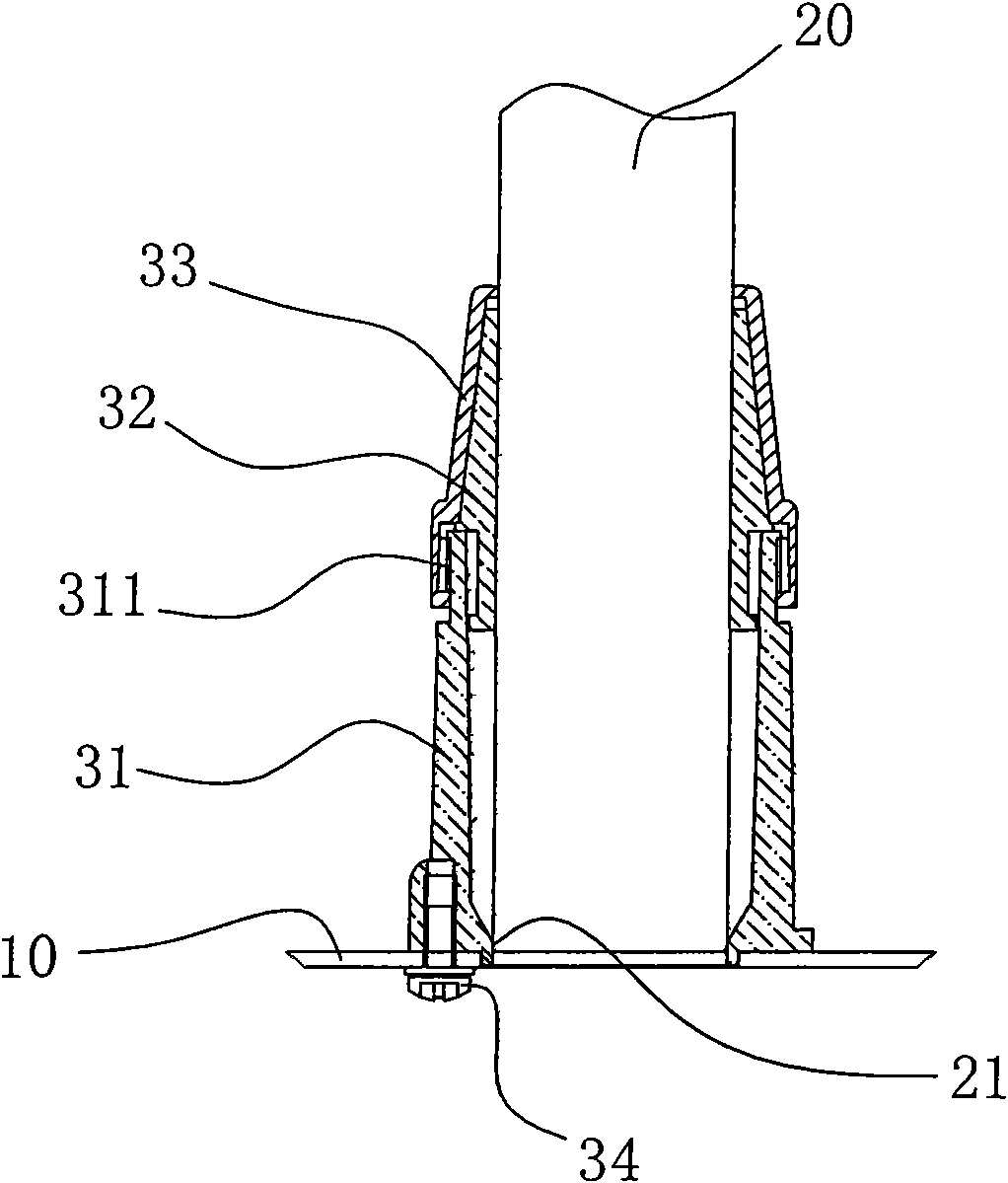

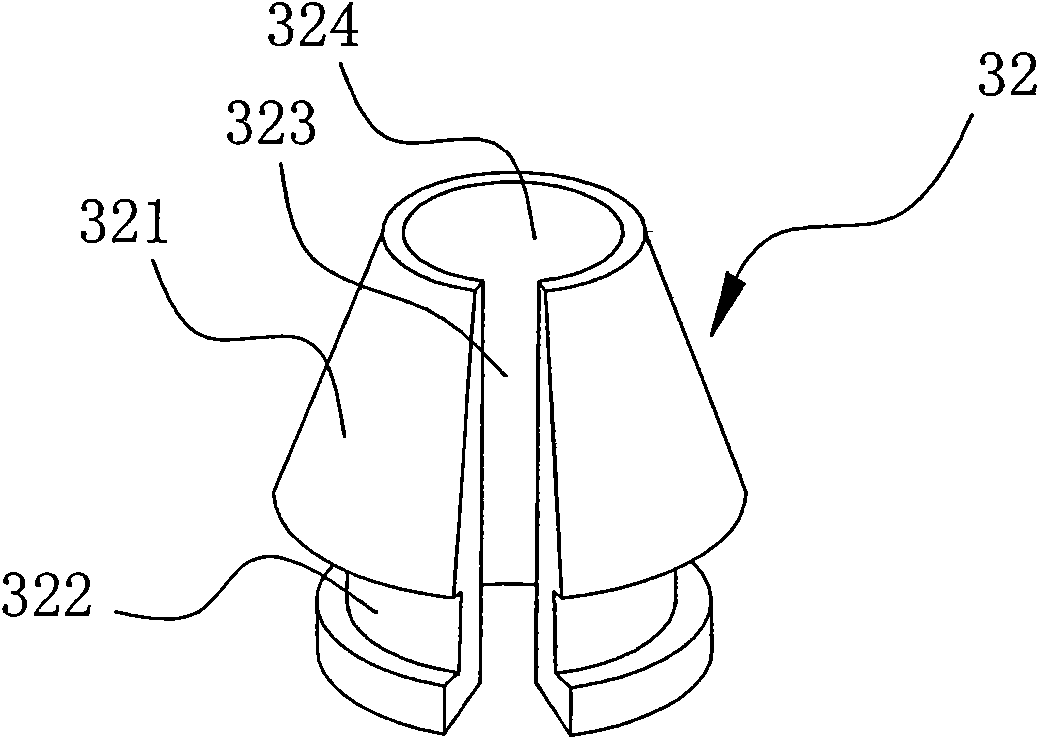

[0022] like figure 1 As shown, the fixed connection structure includes a plate-shaped fixing piece 10, a cylindrical fixed piece 20, and a fixing device 30 that vertically fixes the fixed piece 20 on the fixing piece 10, wherein the fixing device 30 includes a cylindrical fixing seat 31. Locking claw sleeve 32, locking nut 33, a hole is opened on the top of the fixing base 31, the lower part is vertically fixedly connected with the fixing part 10 through a screw 34, and a thread 311 is provided on the outer side wall of the upper part, and the lower end of the fixed part 20 is inserted into the sleeve In the middle hole of the fixing seat 31, the locking claw cover 32 is cylindrical and is set on the fixed part on the upper part of the fixing seat 31. Threaded connection, the surface where the locking claw sleeve 32 cooperates with the inner wall surface of the locking nut 32 is a conical surface. In this fixed connection structure, when the fixed part 10 is fixed, the cylind...

Embodiment 2

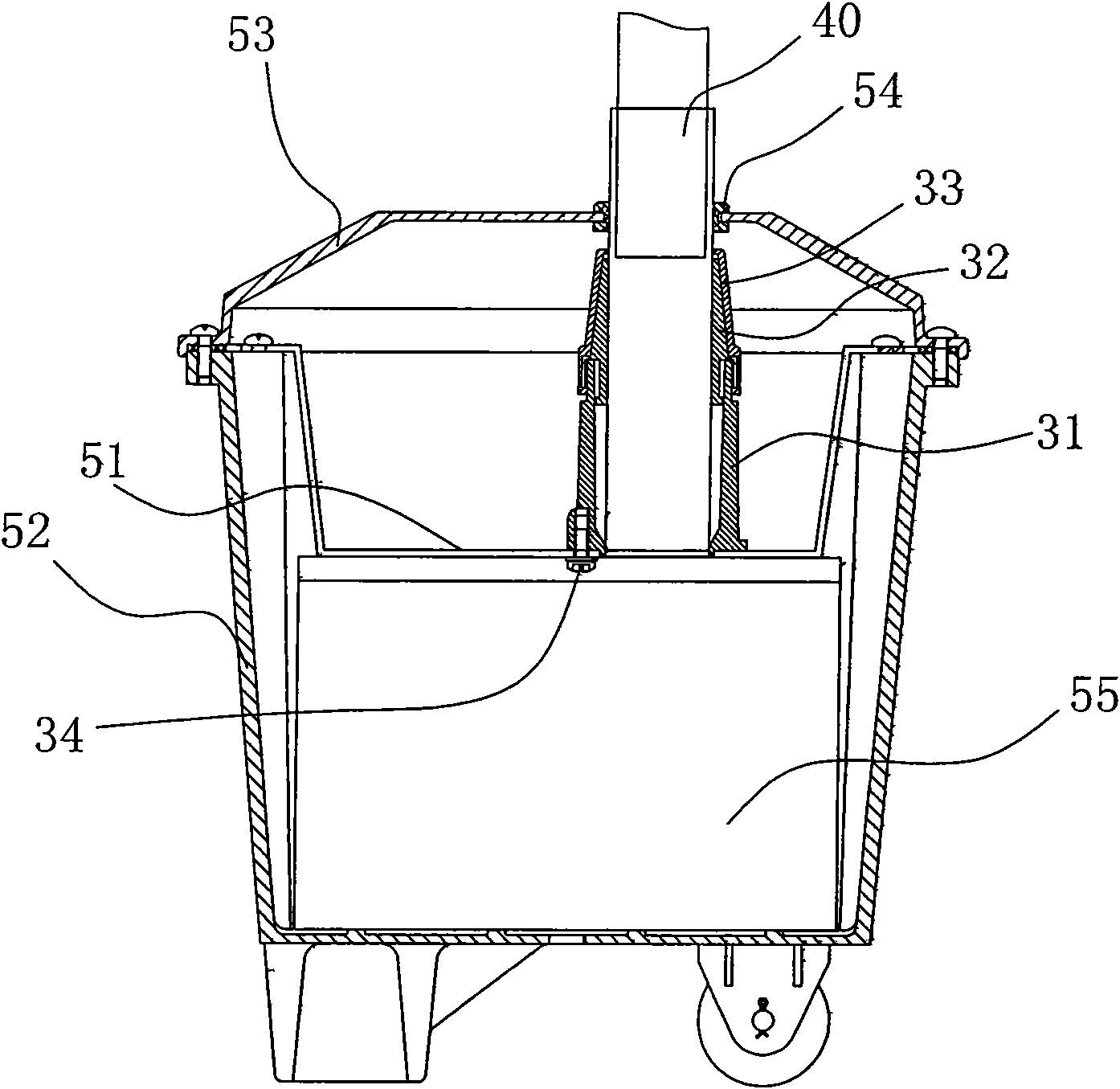

[0027] like image 3 As shown, the floor lamp includes a lamp base assembly, a lamp pole 40, and a fixing device for fixing the lamp pole. The upper part of the lamp pole 40 is connected with a lamp head (the lamp head is not shown in the figure). The lamp holder assembly includes a box body 52, a box cover 53, and a base plate 51. The base plate 51 is fixedly installed in the box body 52, and its outer edge is fixedly connected with the top of the side wall of the box body 52, and forms a box that can be used to place a power supply device. space 55, the lamp pole 40 adopts the fixed connection structure in Embodiment 1 and is vertically fixed on the base plate 51 through the fixing device composed of the fixing seat 31, the locking claw sleeve 32, and the locking nut 33, wherein the fixed connection structure is It has been described in detail in Embodiment 1 and will not be repeated here.

[0028] In this example, if image 3 As shown, the box cover 53 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com