Die clamp

A fixture and mold technology, which is used in the field of fixtures for fixing molds, especially upper molds of bending machines, can solve the problems of very high requirements for spherical bolt locking accuracy, difficulty in implementation, poor adaptability, etc., and achieves easy installation and operation. , Simple structure, strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

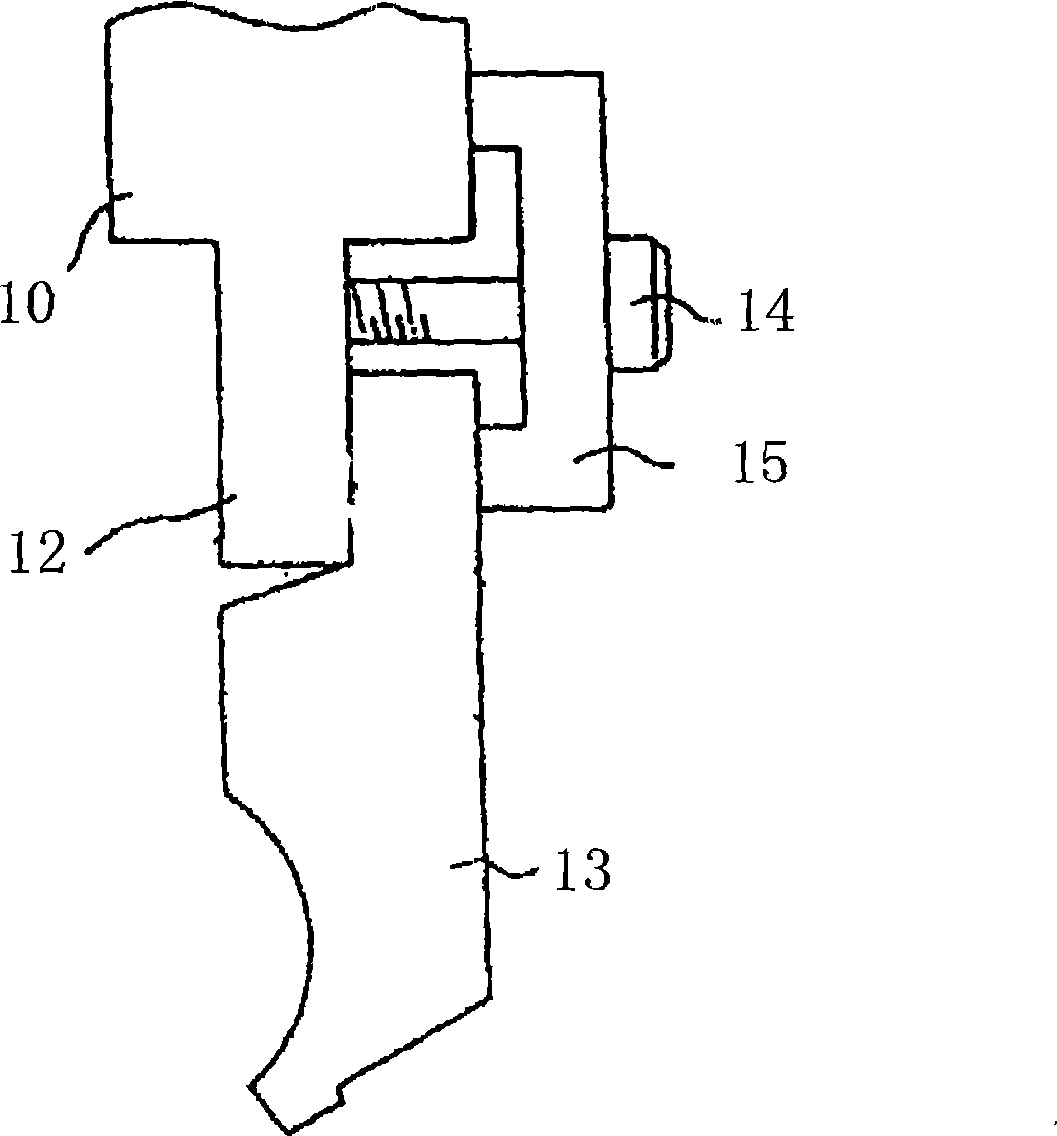

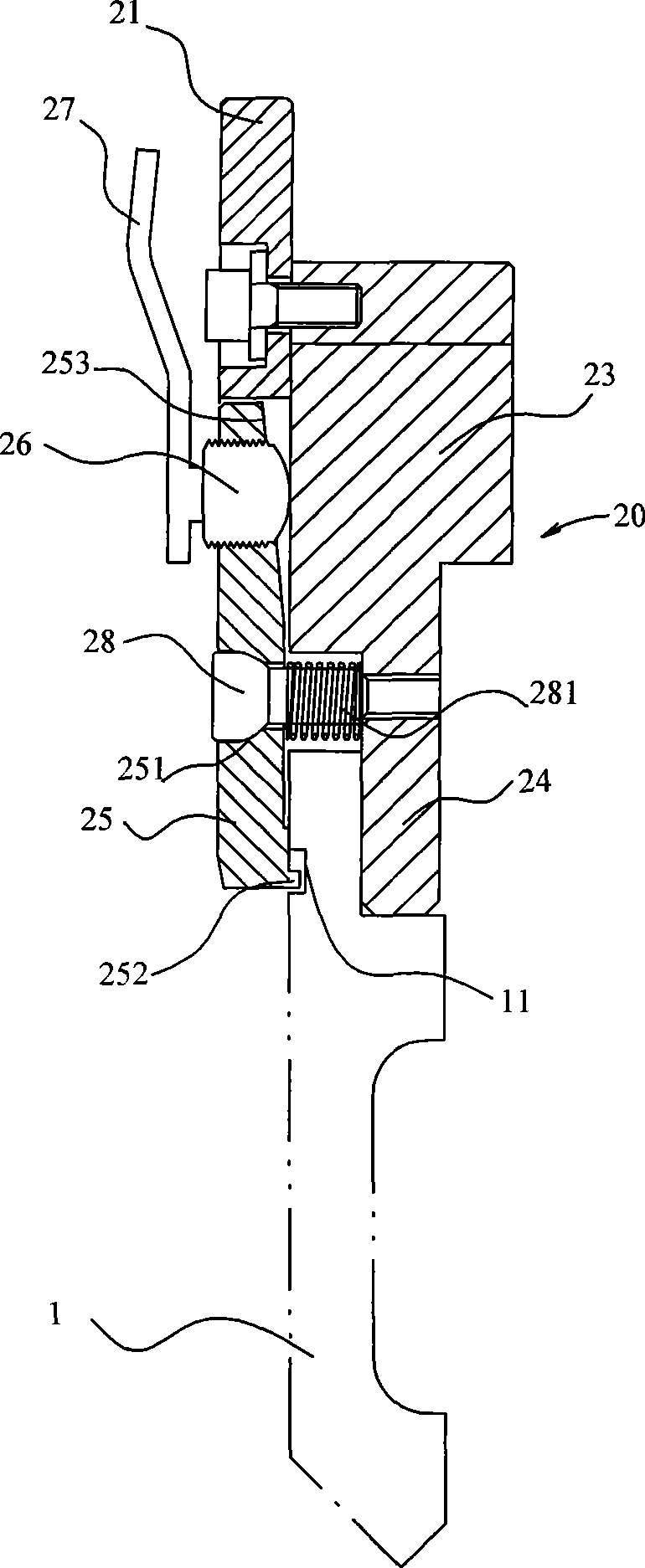

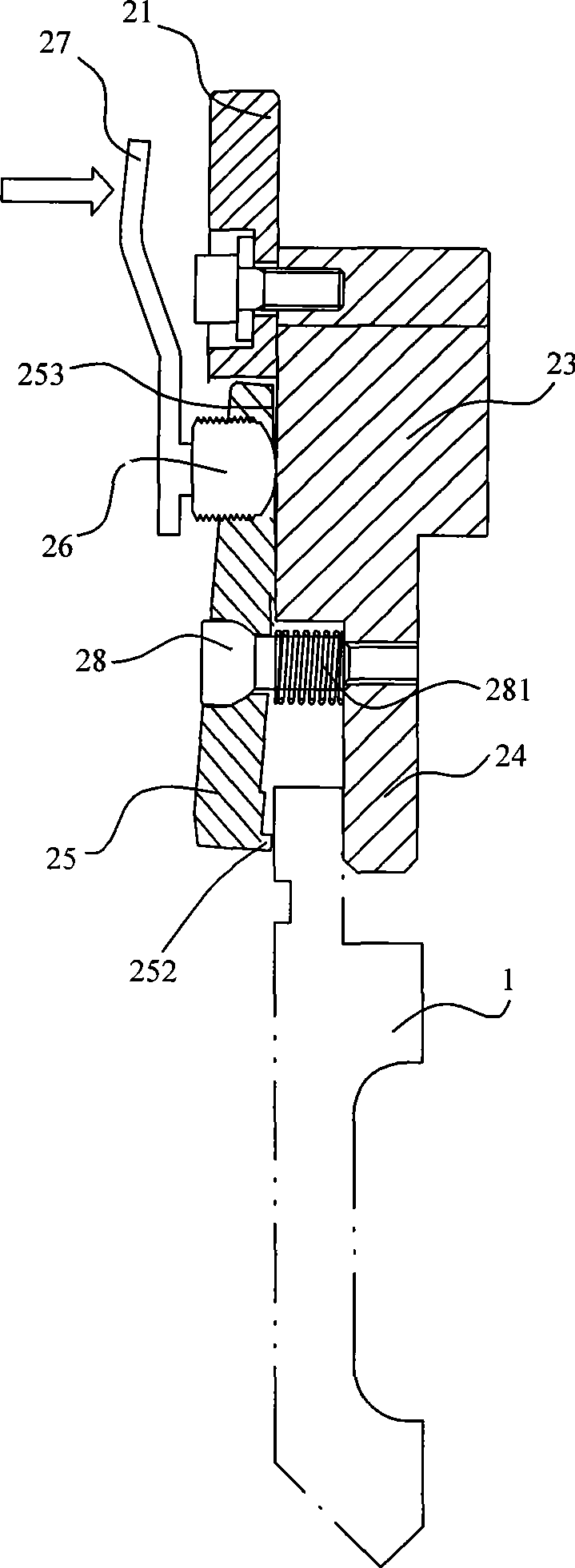

[0038] 3A and 3B show the structure of the mold jig of the first embodiment of the present invention. As shown in the figure, the fixture includes a clamping body 30 detachably mounted on the bottom of the upper workbench 2 through a mounting plate 31. The clamping body 30 includes an upper thick-walled clamping body 33 and a vertical direction along the lower end of the clamping body 33. A thin-walled support plate 34 extending downward. The clamping body 33 is fixed to the mounting plate 31 by a plurality of bolts 311 on the upper part and a plurality of bolts 341 on the lower part, so that it can be installed on the lower part of the upper workbench 2 through the mounting plate 31 . As shown in Figure 3B, the mounting plate 31 is in contact with the lower front side of the upper workbench, and the jaws 22 are fastened on the upper workbench 2 by fastening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com