Bloom continuous casting production course processing simulation and reappearance system

A production process and process simulation technology, which is applied in the field of metallurgical continuous casting production process simulation, can solve the problems that affect the accuracy of the final test results, complex production conditions, and easy to generate waste billets, etc., and achieve an intuitive and easy-to-analyze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

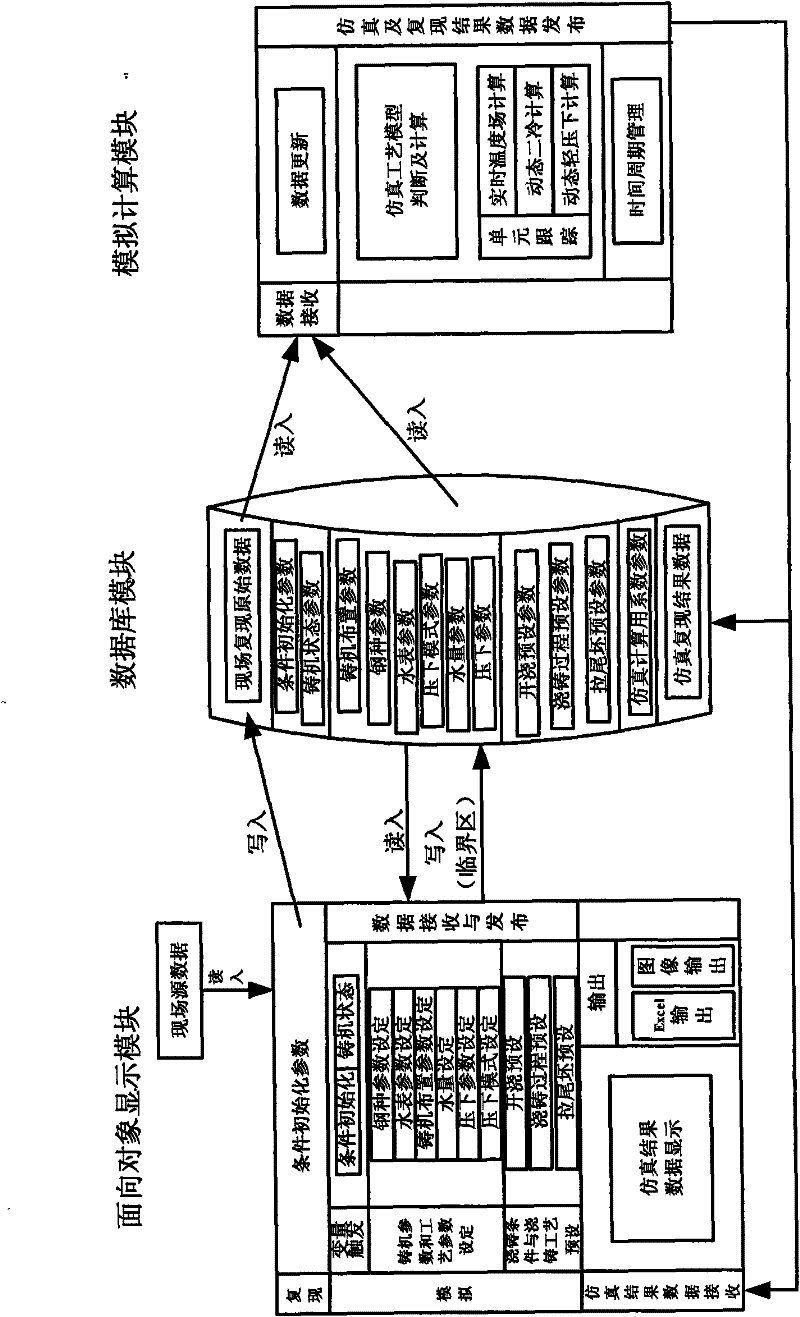

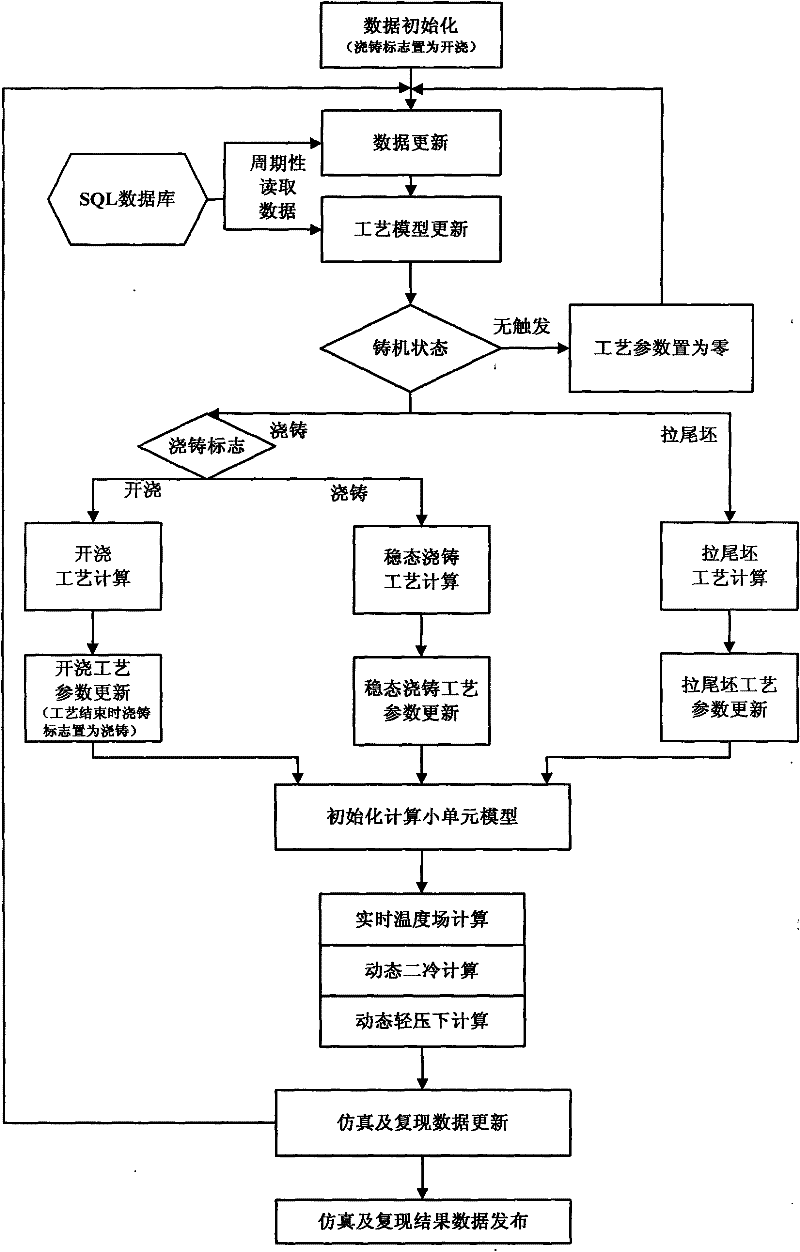

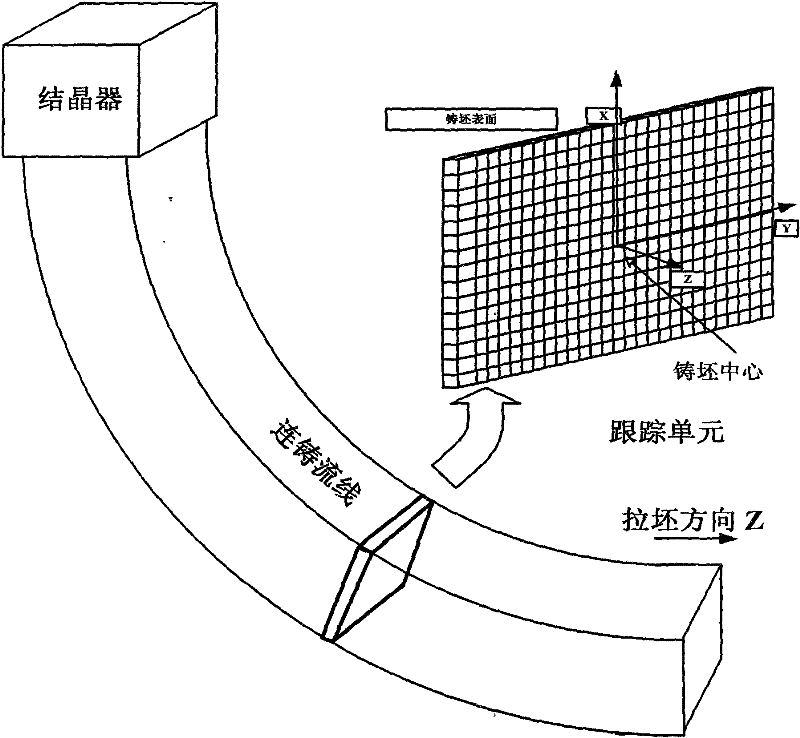

[0027] The present invention is described further in conjunction with accompanying drawing: the system that the present invention proposes is mainly made up of three parts of object-oriented display module, database storage module, simulation computing module, see the attached figure 1 . Among them, the object-oriented display module belongs to the user operation platform, and its functions include ① realizing the initialization input of various process conditions and casting conditions in the process simulation process and the instant input function in the simulation process, and the actual production data storage files in the field reproduction process Read-in function; ②The function of reading the simulation calculation results in real time; ③The function of storing all data in the database module. Database storage module, which is the hub of object-oriented display module and simulation calculation module, including ①storage of simulation condition parameters and process m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com