A method for adjusting the horizontal coil of deflection yoke

A deflecting coil and horizontal line technology is applied in the manufacture of magnetic deflection devices, electrode devices and related components, etc. It can solve the problems of poor convergence grade, waste materials and labor, and affect the competitive advantage of products, and achieve less usage and improved convergence grade. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 7

[0028] Embodiment one 37cm15X deflection yoke

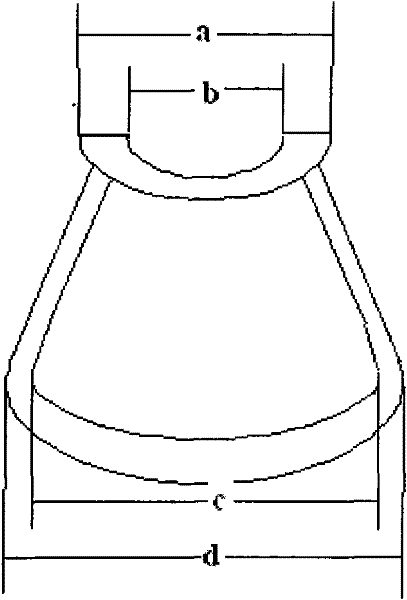

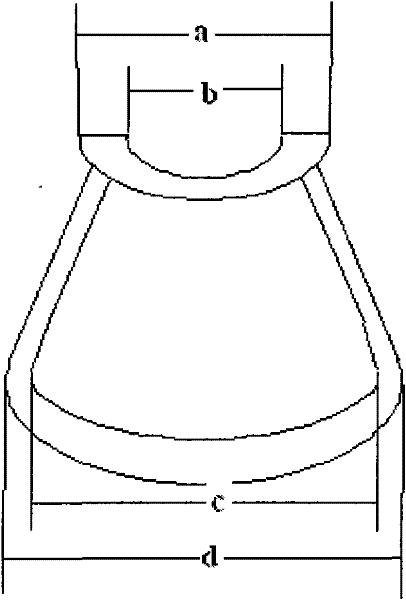

[0029] The first step is to measure the diameter a of the neck of the outer cavity of the horizontal coil, the diameter of the opening of the outer cavity of the horizontal coil d, the diameter of the neck of the inner cavity of the horizontal coil b, and the diameter of the opening of the inner cavity of the horizontal coil coil c, where a=36mm, b= 5mm, c=52mm, d=77mm;

[0030] The second step, according to the following formula (1), (2), calculate K1, K2,

[0031] a / d=K1 (1)

[0032] b / c=K2 (2)

[0033] K1=a / d=36 / 77=0.4675 is fixed value,

[0034] K2=b / c=5 / 52=0.096;

[0035] The third step is to adjust b from 5mm to b’=16mm, c from 52mm to c’=57mm, and calculate K2’

[0036] K2'=b' / c'=16 / 57=0.28 then

[0037] K1-K2'=0.1475 K1-K2=0.3695

[0038] K1-K2'

[0039] Advantages after adjustment: ①The green drop angle is changed from 0.8mm to 0.5mm; ②Half-point convergence is 1.0mm, reduced to 0.5mm; ③XH+convergence is 0....

Embodiment 2 4

[0040] Embodiment two 54cmFS deflection yoke

[0041] The first step is to measure the diameter a of the neck of the outer cavity of the horizontal coil, the diameter of the opening of the outer cavity of the horizontal coil d, the diameter of the neck of the inner cavity of the horizontal coil b, and the diameter of the opening of the inner cavity of the horizontal coil coil c, where a=31mm, b= 4mm, c=52mm, d=72mm;

[0042] The second step, according to the following formula (1), (2), calculate K1, K2,

[0043] a / d=K1 (1)

[0044] b / c=K2 (2)

[0045] K1=a / d=31 / 72=0.43 is fixed value,

[0046] K2=b / c=4 / 52=0.076;

[0047] The third step is to adjust b from 4mm to b’=7mm; adjust c from 52mm to c’=57mm; calculate K2’

[0048] K2'=b' / c'=7 / 57=0.1228 then

[0049] K1-K2'=0.3072 K1-K2=0.354

[0050] K1-K2'

[0051] Advantages after adjustment: ①Remove the pins at the neck and opening; ②The upper and lower trapezoidal distortion is adjusted from up + down = 7mm to up + d...

Embodiment 3 4

[0052] Embodiment 3 Deflection yoke of 64cmPF

[0053] The first step is to measure the diameter a of the neck of the outer cavity of the horizontal coil, the diameter of the opening of the outer cavity of the horizontal coil d, the diameter of the neck of the inner cavity of the horizontal coil b, and the diameter of the opening of the inner cavity of the horizontal coil coil c, where a=38mm, b= 12mm, c=55mm, d=85mm;

[0054] The second step, according to the following formula (1), (2), calculate K1, K2,

[0055] a / d=K1 (1)

[0056] b / c=K2 (2)

[0057] K1=a / d=38 / 85=0.447 is fixed value,

[0058] K2=b / c=12 / 55=0.218:

[0059] The third step is to adjust b from 12mm to b'=18mm; adjust c from 55mm to c'=57mm; calculate K2'

[0060] K2'=b' / c'=18 / 57=0.315

[0061] K1-K2'=0.132 K1-K2=0.229

[0062] Then K1-K2'

[0063] Advantages after adjustment: ①The pincushion shape of the half-point horizontal line changes from 1.0mm to 0.6mm; ②The pincushion shape of 4 corners chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com