Harmonic-var comprehensive compensation system based on two-way dynamic reactive power compensation devices

A compensation device and comprehensive compensation technology, which is applied in the field of harmonic and reactive power comprehensive compensation systems, can solve the problems of not being able to adapt to fast response occasions, increase APF capacity, and aggravate APF burden, so as to reduce volume, reduce cost, and reduce The effect of compensating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

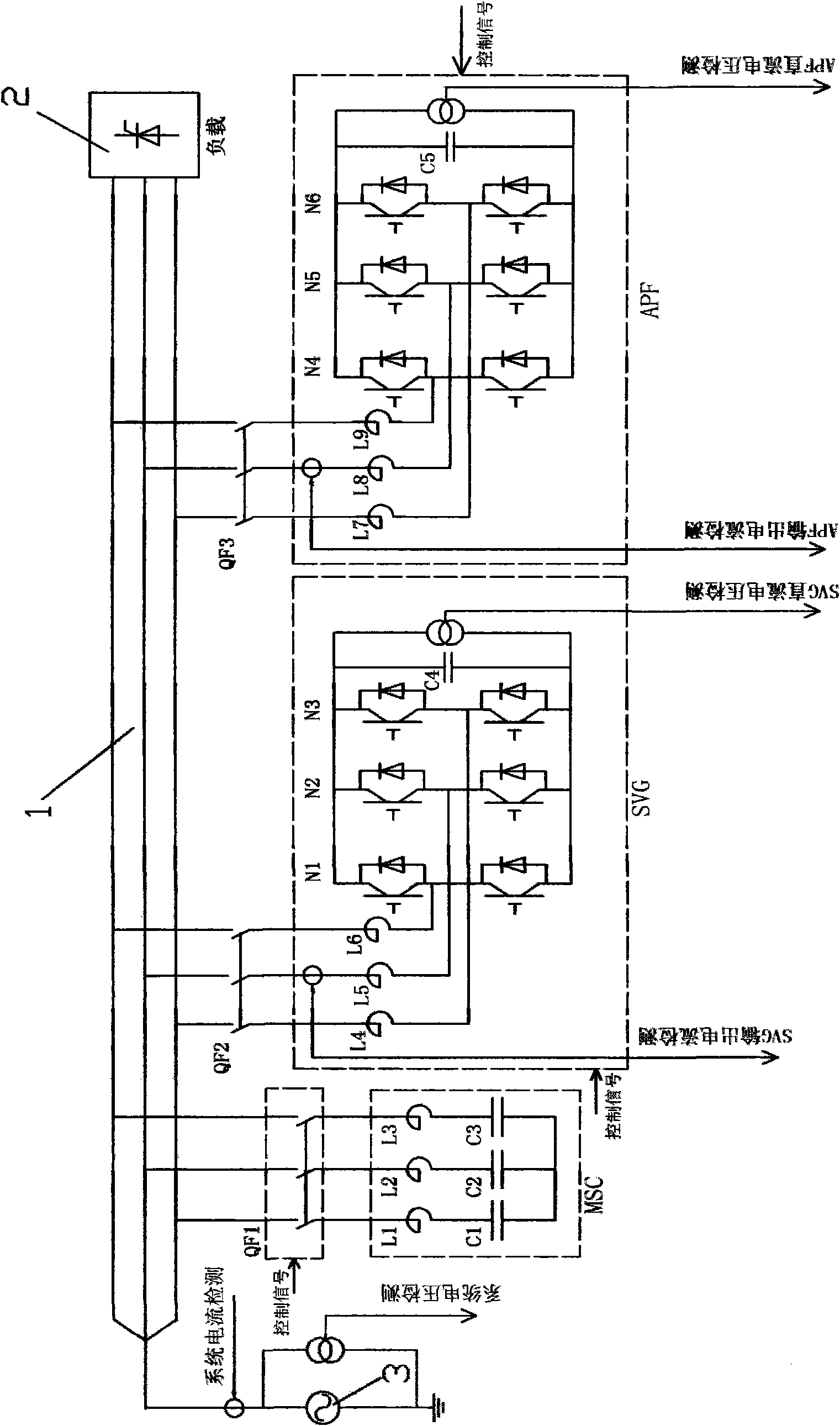

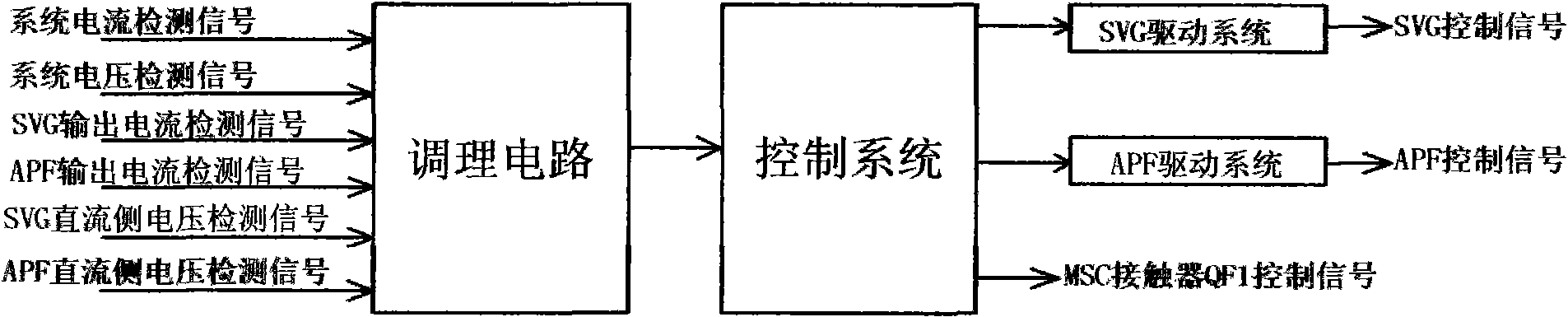

[0017] see figure 1 , the system consists of SVG, MSC and APF connected to grid 1. The following still uses a 2M system as an example to illustrate that the maximum reactive capacity required to be compensated by the power grid is 2M, so the reactive capacity of MSC and SVG in the system needs to be designed to be 1M each, and the 1M capacitive reactive capacity of MSC is used for fixed investment. Switch, the output reactive capacitive capacity is 0 or 1M, SVG can output capacitive reactive capacity 1M to inductive capacity 1M by adjusting, so the reactive power compensation capacity output by the system can be continuous between inductive 1M and capacitive 2M The change meets the capacitive reactive power compensation of the power grid 2M, and at the same time, it can also meet the inductive reactive power compensation of the power grid 1M. Generally speaking, the amount of inductive compensation required by the grid is smaller than the amount of capacitive compensation, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com