Laser automatic focusing blow-spraying mechanism

An automatic focusing and laser technology, applied in the field of marking, can solve the problems of inconsistent character depth, labor-intensive, poor effect, etc., and achieve the effect of consistent engraving depth, increasing engraving depth, and clear engraving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

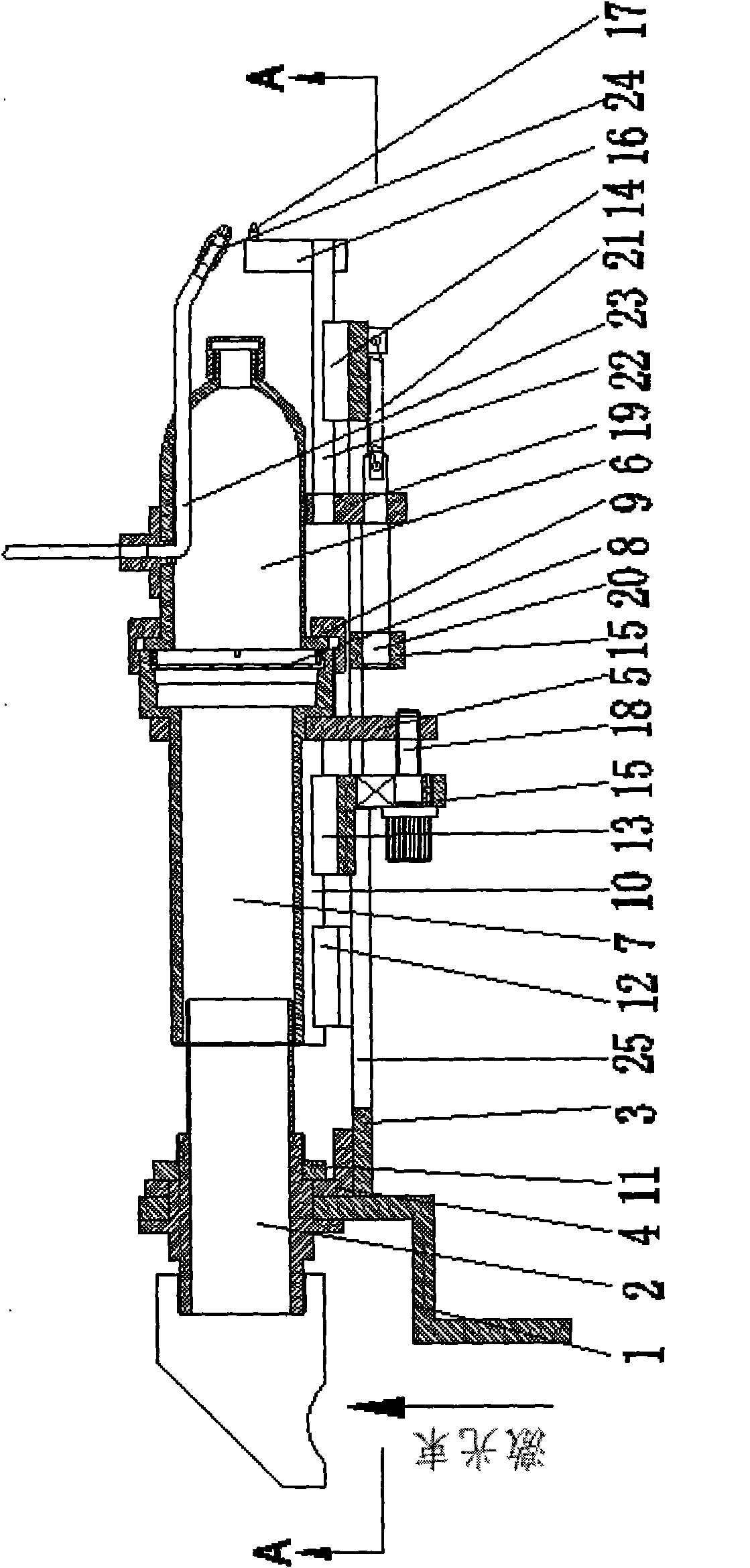

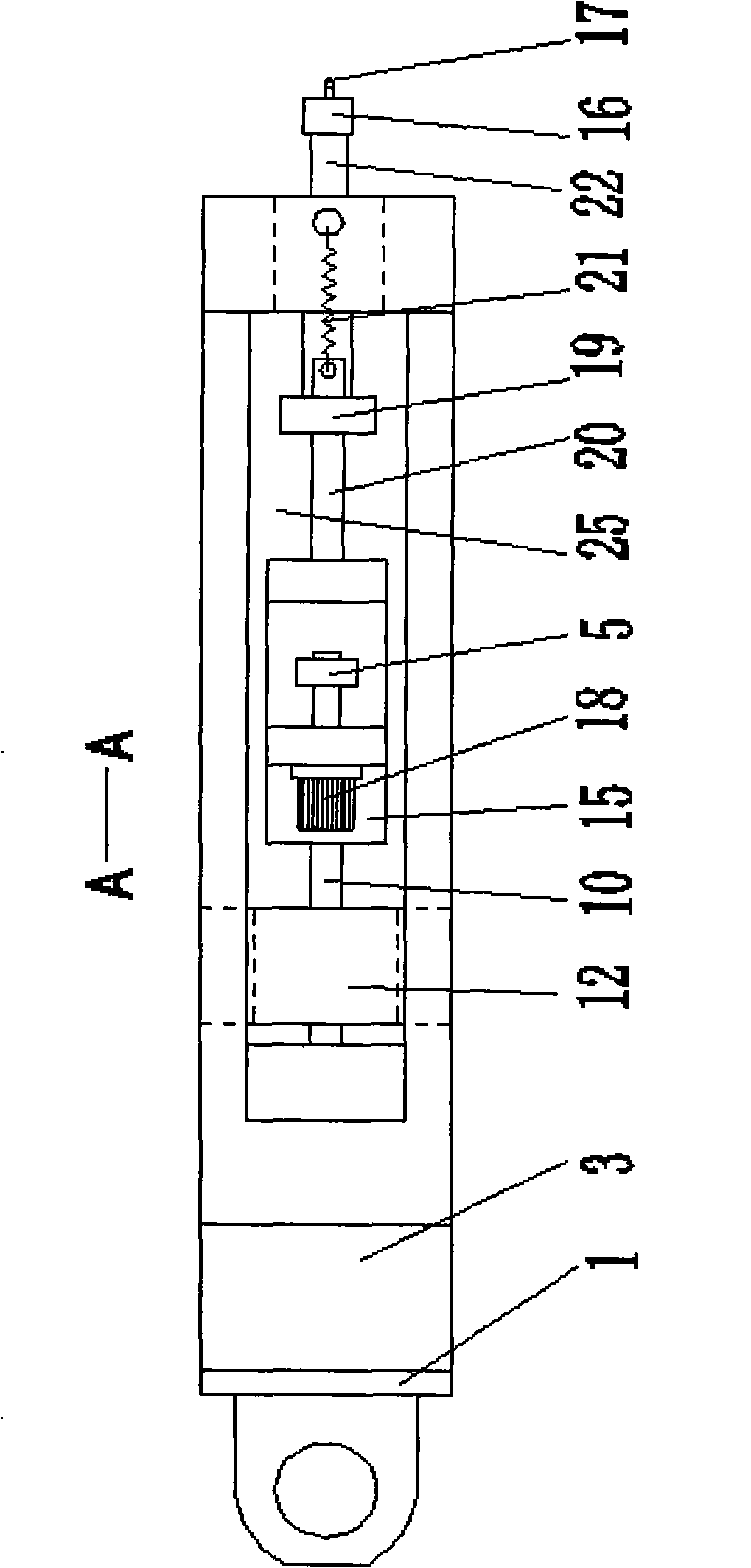

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] See figure 1 and figure 2 : The laser auto-focusing blowing mechanism shown includes a fixed bracket 1, a fixed lens barrel 2, a fixed plate 3, a fixed sleeve 4, a blowing mechanism, and the focus lens barrel that can move the laser along the beam direction and drive the movement The focusing mechanism and other components for the movement of the focusing lens barrel, the fixed lens barrel 2 is set on the fixed bracket 1, and the fixed lens barrel 2 is attached to the fixed bracket 1 to cover the fixed sleeve 4, and then the fixed sleeve 4 is fixed. Covered with a fastening sleeve 11, the front end of the fixed lens barrel 2 is looped on the moving focusing lens barrel, and the middle part of the moving focusing lens barrel is fixedly sleeved with a holding tube 5, and a fixed lens is arranged below the moving focusing lens barrel. Plate 3, one end of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com