Hoist

A hoist and motor technology, applied in the field of hoist, can solve the problems of increased number of heat sink 120 parts, deterioration of heat dissipation, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

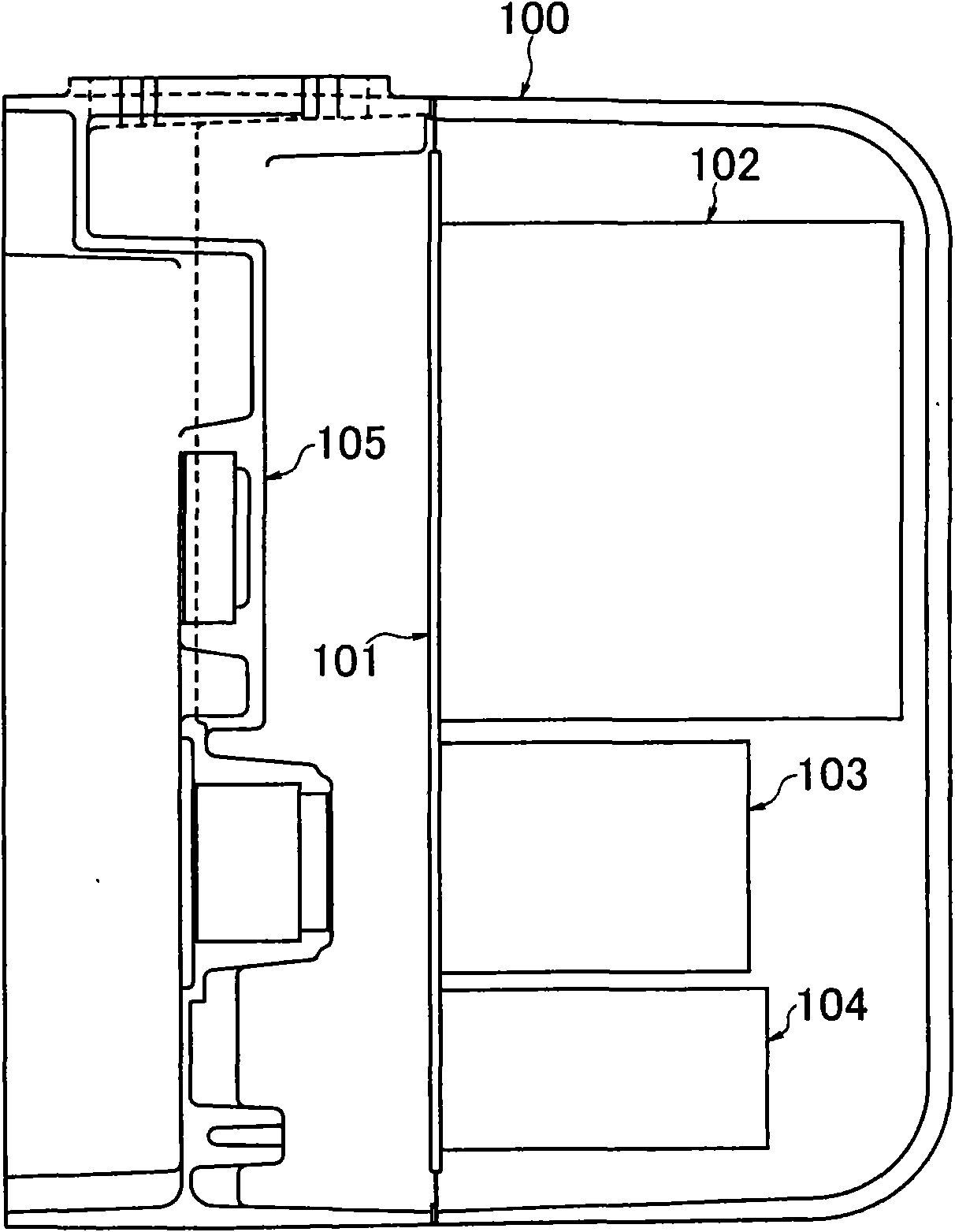

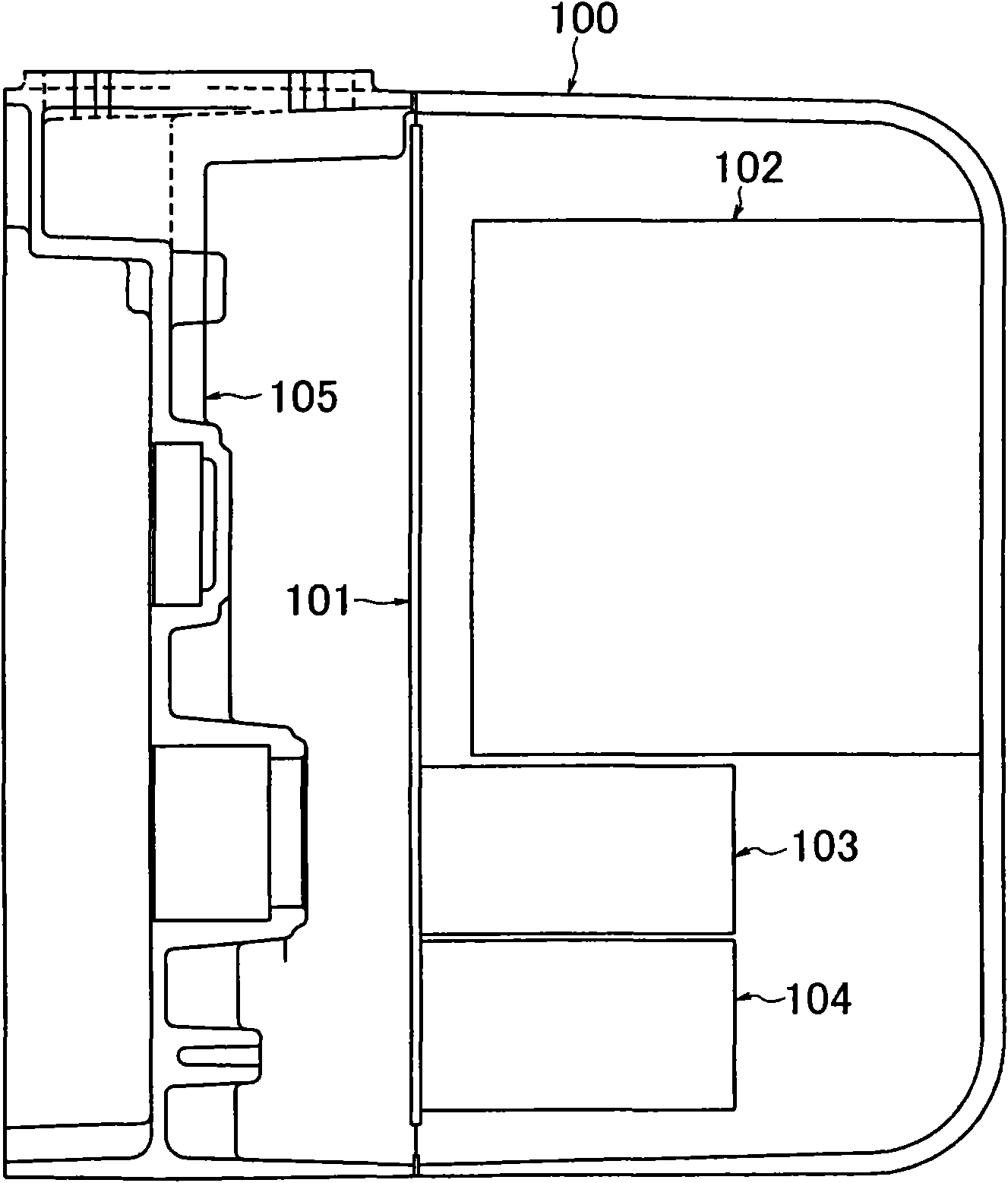

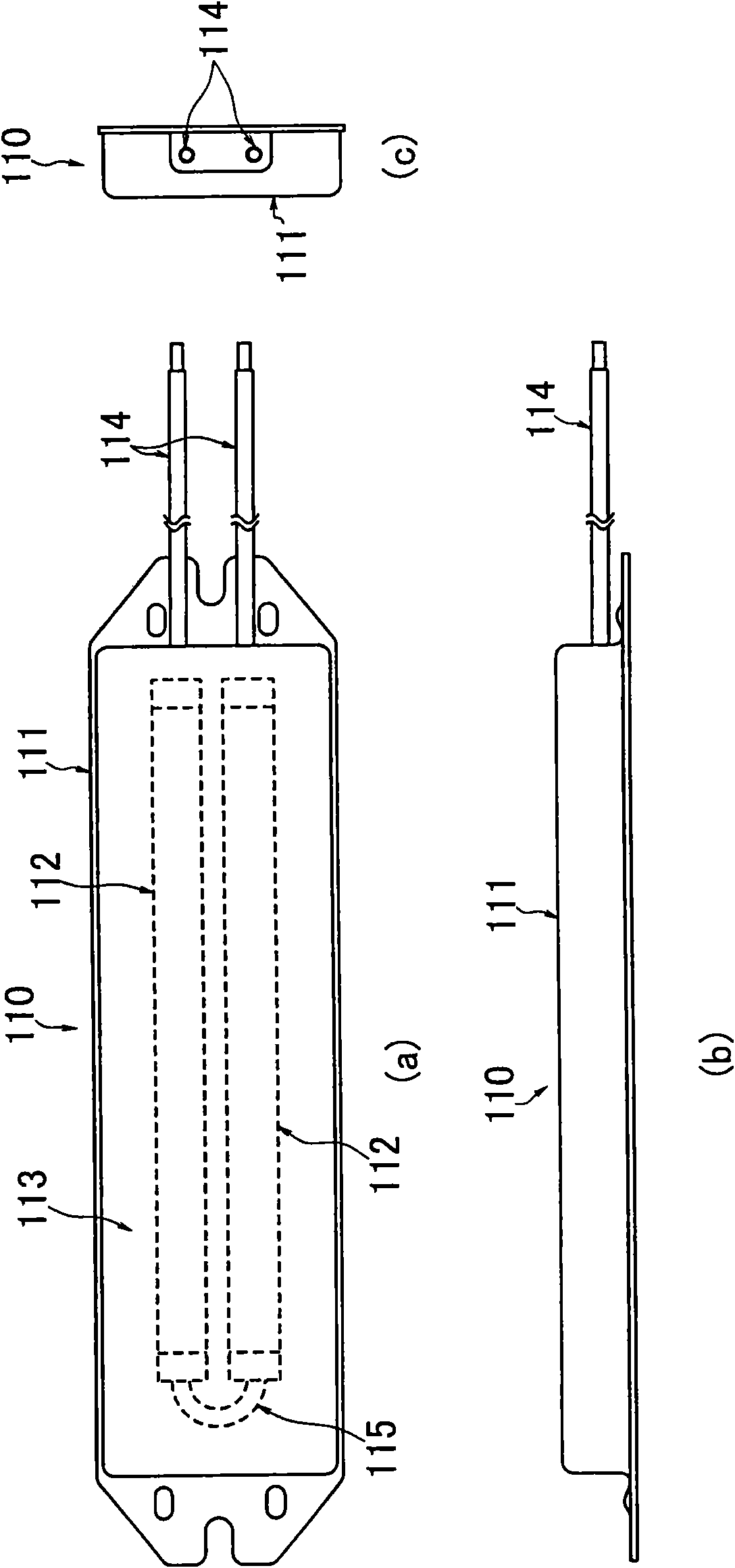

[0053] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Figure 5 It is a plan sectional view showing an example of the internal structure of the control box of the electric chain block of the present invention. As shown in the figure, the inverter 12 is directly mounted on the reduction mechanism housing 15 . At this time, the contact surfaces of the inverter 12 and the speed reduction mechanism case 15 are formed flat with each other, and both are mounted in close contact (in close contact with each other). The reduction mechanism case 15 is formed by aluminum die-casting, and lubricating oil (not shown) for lubricating gears and the like (not shown) constituting the reduction mechanism is housed in the reduction mechanism case 15 .

[0054] In addition, an electromagnetic switch 13 and a transformer 14 mounted on a steel panel 11 are arranged in the control box 10 . In the case of high-frequency operation of the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com