Device for measuring weight of liquid asphalt

A technology for liquid asphalt and asphalt, applied in the field of equipment for measuring the weight of liquid asphalt, can solve the problems of large fluctuation in the quality of asphalt mixture, uncontrollable below 2%, and decreased measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

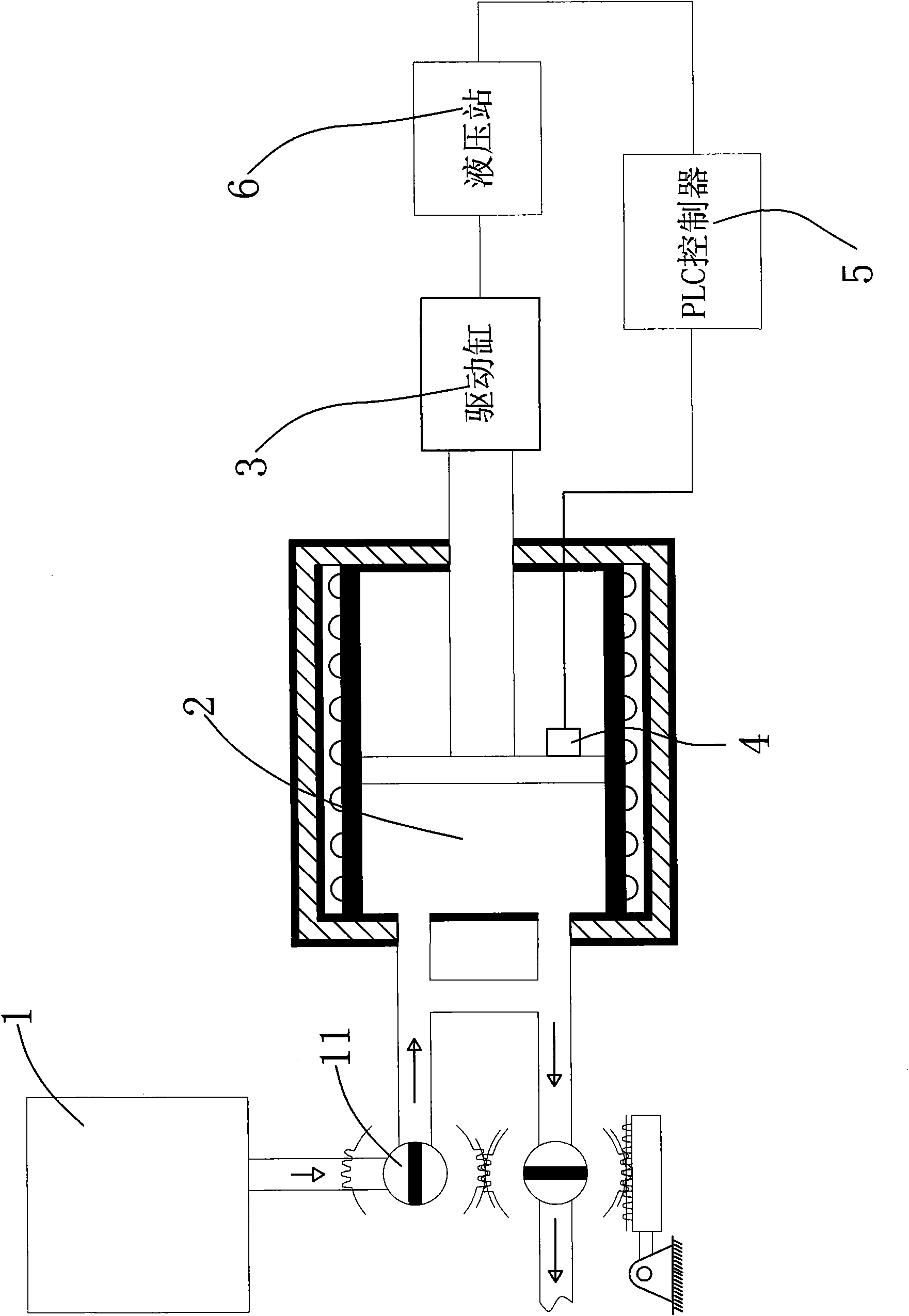

[0007] from figure 1 It can be seen that the equipment for measuring the weight of liquid asphalt provided by the present invention includes an asphalt tank 1, an asphalt measuring cylinder 2, and a drive cylinder 3. The asphalt tank 1 is connected with the asphalt measuring cylinder 2 through a switch valve 11, and the asphalt measuring cylinder The piston of 2 is driven by the drive cylinder 3, the piston or piston rod of the asphalt metering cylinder 2 is equipped with a displacement sensor 4, the displacement sensor 4 is connected with the PLC controller 5, and the PLC controller 5 controls the drive cylinder 3 through the hydraulic station 6.

[0008] When the present invention is used, the operator first inputs the required asphalt weight value into the PLC controller 5, and the PLC controller 5 converts the weight value into the designated distance that the piston in the asphalt measuring cylinder should move according to the density of the liquid asphalt and stores it, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap