Display cell

A display unit and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of inability to separate the useless substrate W, broken CF substrate 130, weak strength, etc., and achieve the effect of suppressing poor segmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

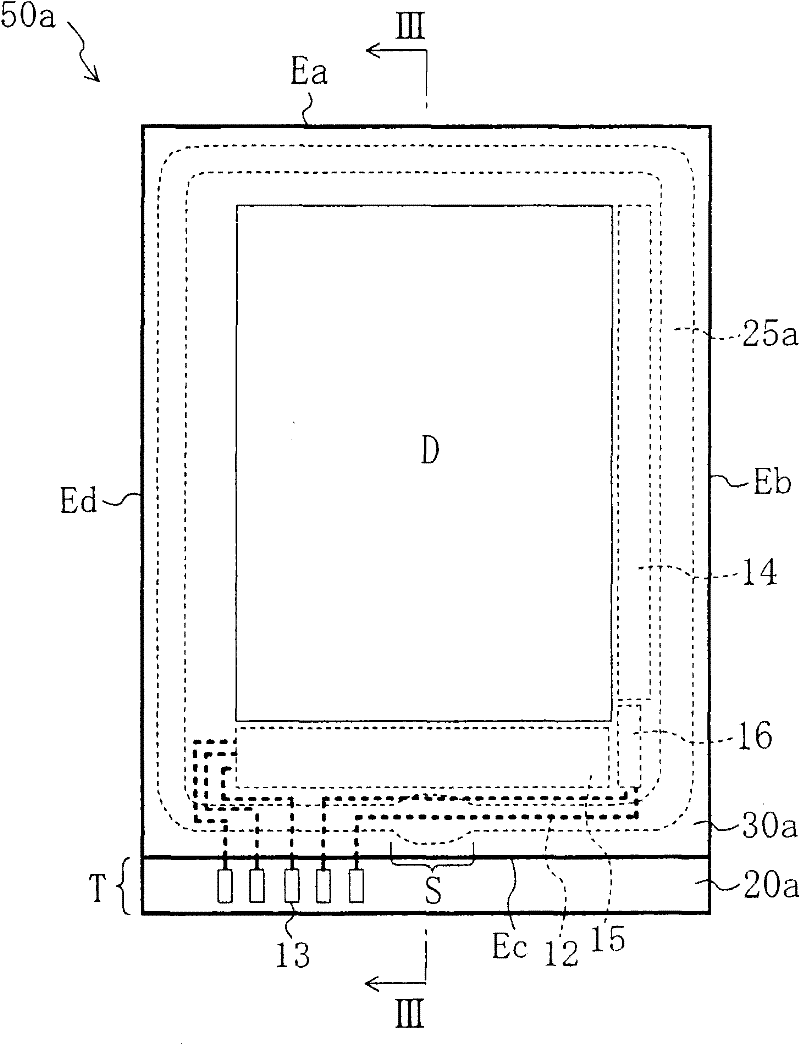

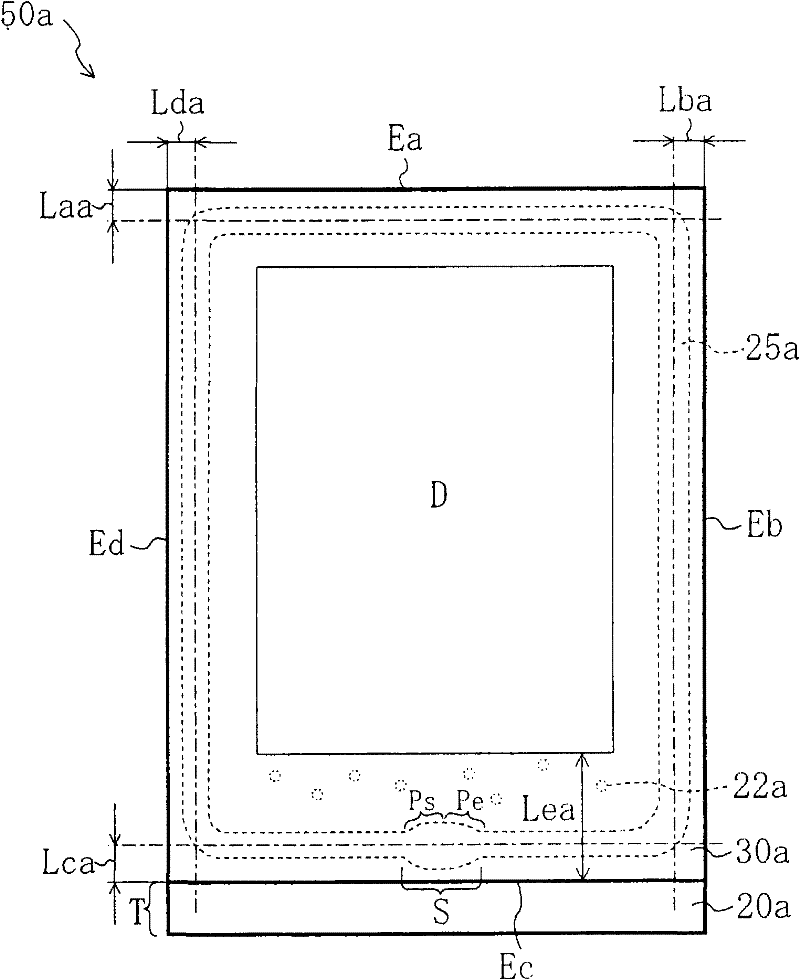

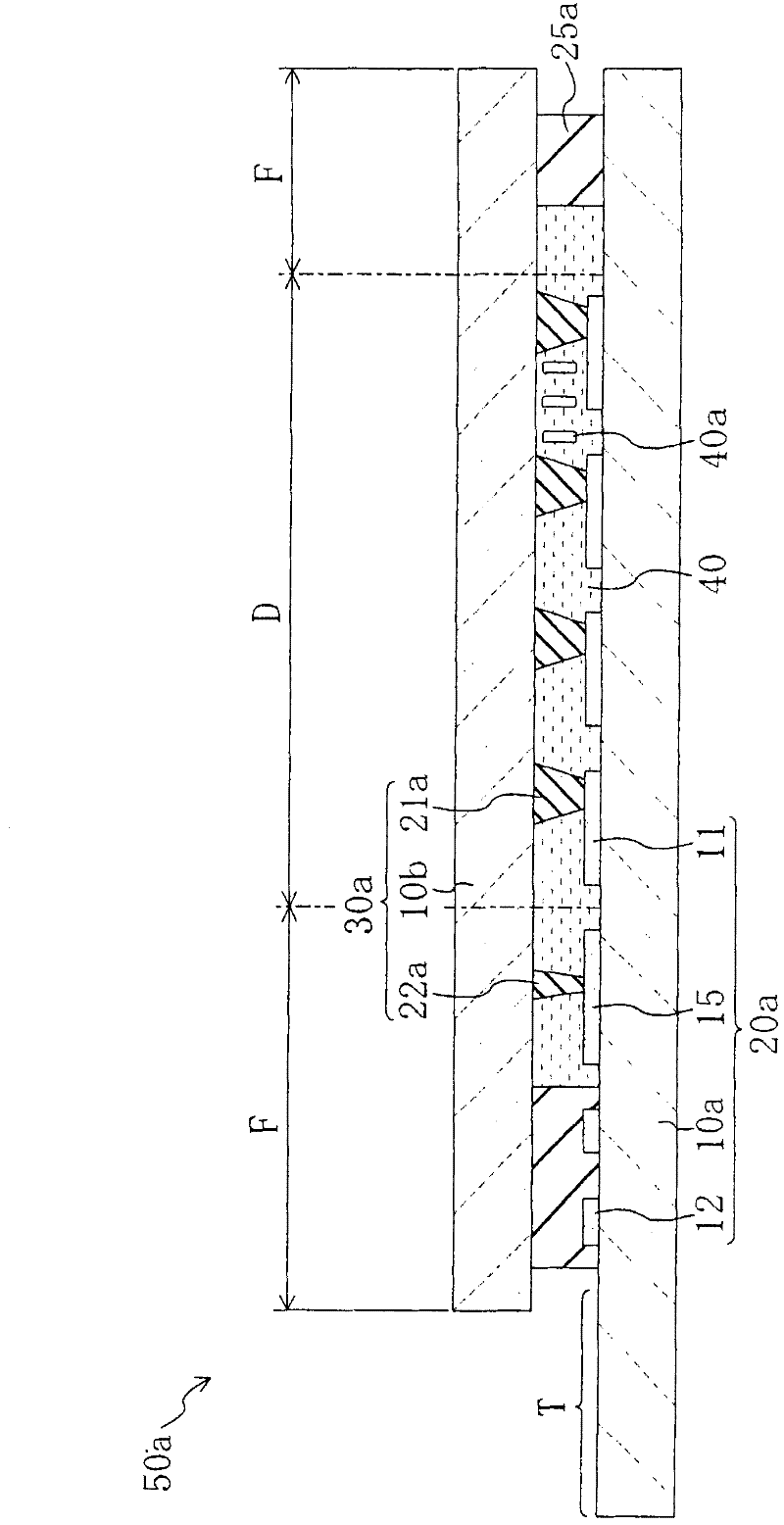

[0069] Figure 1 ~ Figure 3 Embodiment 1 of the display unit (liquid crystal unit) of the present invention is shown.

[0070] Specifically, figure 1 is a plan view of the liquid crystal cell 50a of this embodiment, figure 2 is a plan view for explaining the structure of the sealing material 25a of the liquid crystal cell 50a, and image 3 is along figure 1 A cross-sectional view of the liquid crystal cell 50a on line III-III.

[0071] Such as Figure 1 ~ Figure 3 As shown, the liquid crystal unit 50a includes: a TFT substrate 20a as a first substrate, a CF substrate 30a as a second substrate disposed opposite to the TFT substrate 20a, a liquid crystal layer 40 between the TFT substrate 20a and the CF substrate 30a, and a TFT The substrate 20 a and the CF substrate 30 a are bonded to each other, and a frame-shaped sealing material 25 a of the liquid crystal layer 40 is sealed between the TFT substrate 20 a and the CF substrate 30 a.

[0072] Additionally, if Figure ...

Embodiment approach 2

[0114] Figure 4 ~ Figure 6 Embodiment 2 of the display unit (liquid crystal unit) of the present invention is shown. In addition, in each of the following embodiments, with Figure 1 ~ Figure 3 For the same parts, the same symbols are used, and detailed description thereof will be omitted.

[0115] In Embodiment 1 described above, the structure in which the gate driver circuit 14 and the source driver circuit 15 are monolithically formed was exemplified, but the present invention is not limited to this structure.

[0116] Specifically, Figure 4 is a plan view of the liquid crystal cell 50b of this embodiment, Figure 5 is a plan view for explaining the structure of the sealing material 25a of the liquid crystal cell 50b, and Figure 6 is along Figure 4 A cross-sectional view of the liquid crystal cell 50b on line VI-VI.

[0117] Such as Figure 4 ~ Figure 6 As shown, the liquid crystal unit 50b has: a first substrate, namely a TFT substrate 20b; a second substrate di...

Embodiment approach 3

[0139] Figure 7 Embodiment 3 of the display unit (liquid crystal unit) of the present invention is shown. Specifically, Figure 7 It is a plan view which shows the liquid crystal cell 50c of this embodiment.

[0140] In each of the above-mentioned embodiments, the sealing material 25a on one side having the sealing joint S is uniformly far from the end of the CF substrate from one end to the other end of the side, but in this embodiment, only the sealing material 25a having the sealing joint S A part of one side of the sealing material 25b is bent toward the display region D side, and a sealing joint S is formed at this part.

[0141] According to the liquid crystal cell 50c of this embodiment, since the sealing joint part S of the sealing material 25b is away from the edge part of the CF board|substrate 30a similarly to each of the above-mentioned embodiment, the division defect by the sealing joint part S can be suppressed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com