Method and device for dividing brittle substrate

A brittle substrate, substrate technology, applied in glass cutting devices, transportation and packaging, conveyors, etc., can solve problems such as poor segmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

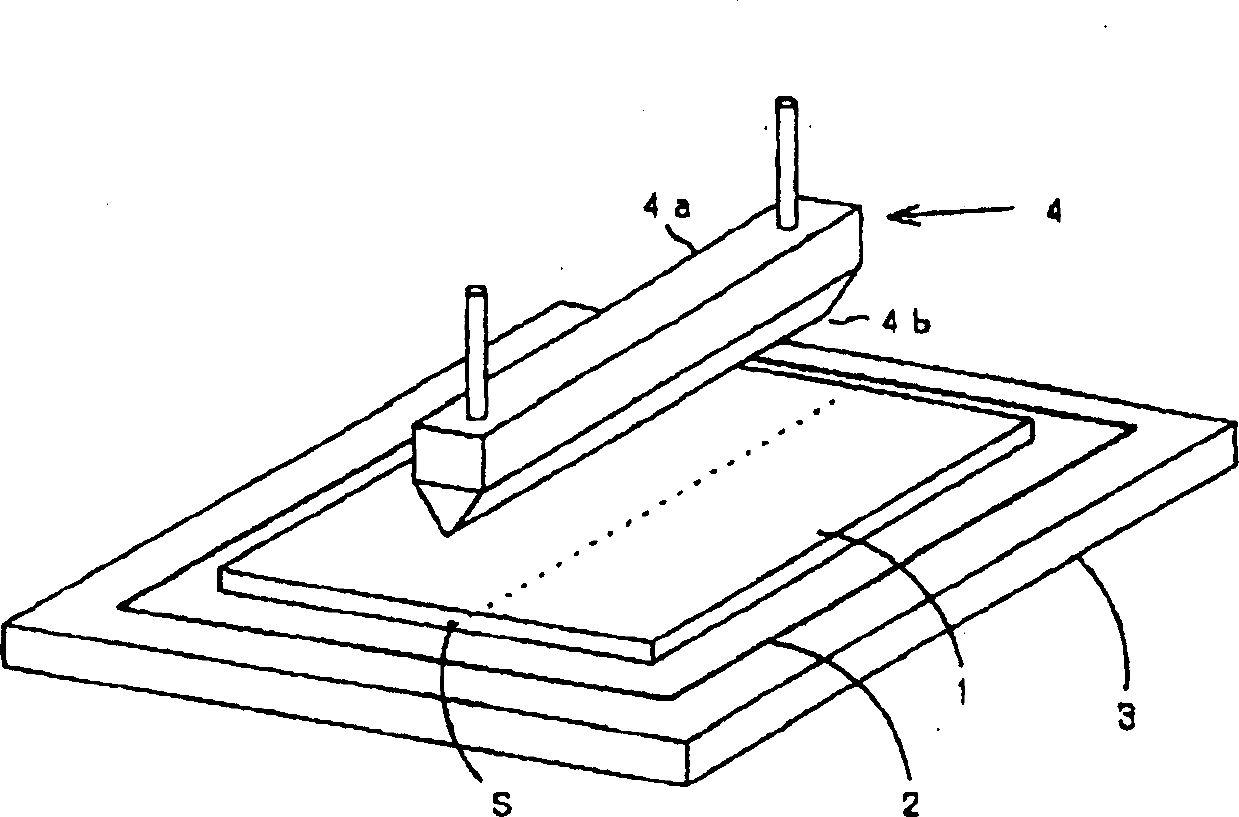

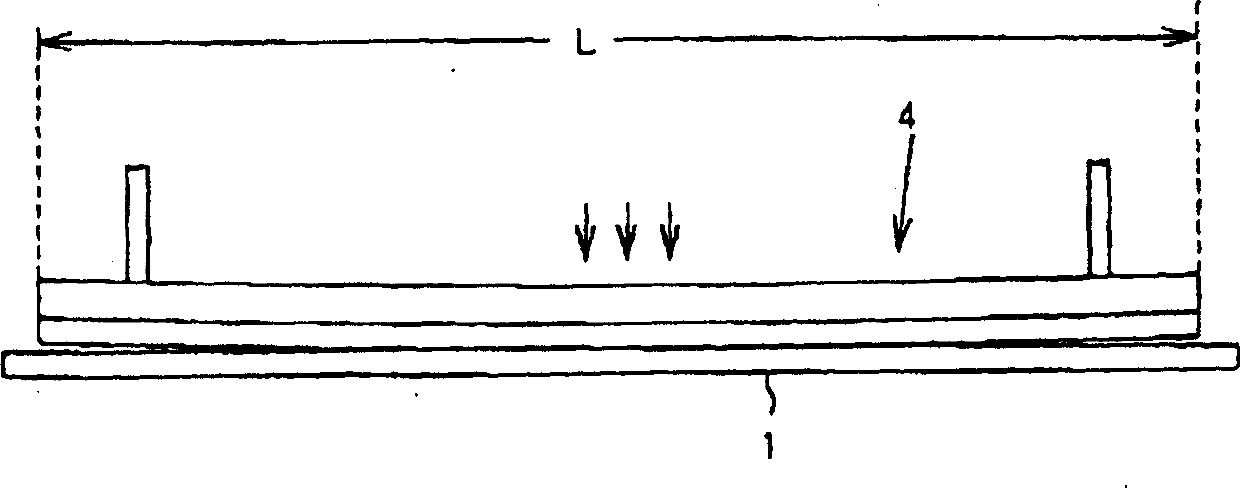

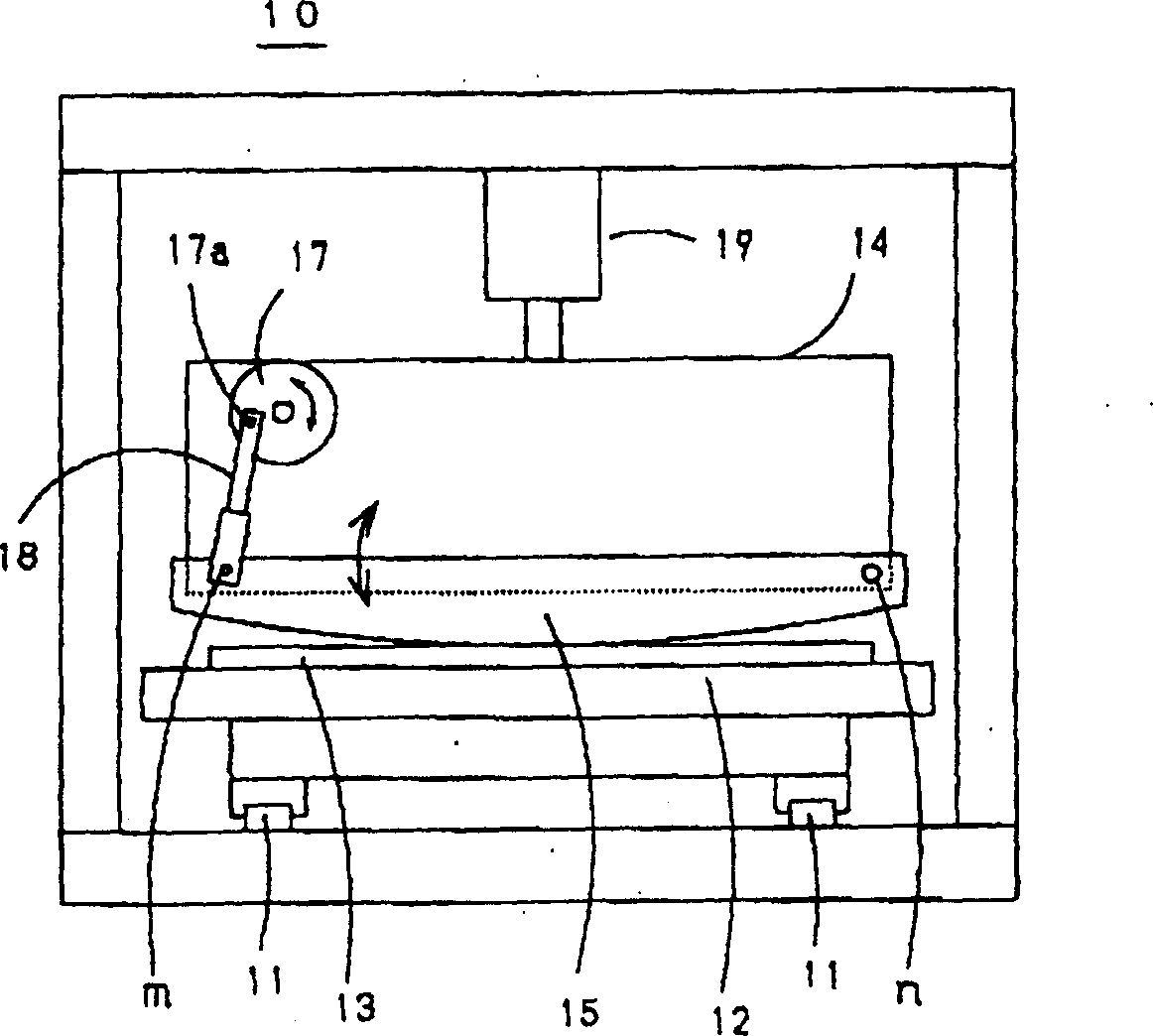

[0020] image 3 It is a front view of a brittle substrate dividing apparatus 10 according to the first embodiment of the present invention. Figure 4 It is a side view of the dividing apparatus 10 for a brittle substrate, and only an enlarged view of a main part related to the present invention is shown. In the Y direction ( image 3 On the movable workbench 12 in the vertical direction of the paper plane), a pair of guide members 11 is used to install a glass plate 13 with the drawn score line facing downward. A flat split rod support body 14 is positioned above the workbench 12 in an inverted state, and a split rod 15 is provided at the lower portion of the split rod support body 14 .

[0021] The dividing rod 15 as Figure 5 As shown, it consists of a bow-like curved base 15a below and a hard rubber 15b joined thereunder.

[0022] Pin holes m and n are formed at both ends of the split rod 15 , and the split rod 15 is provided so as to be rotatable relative to the split ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com