Protection method and protection device thereof when using punch

A technology of protection device and punching machine, which is applied in the field of punching and stamping, can solve problems such as complicated operation, large space occupation, and reduced production efficiency, and achieve the effects of rapid response process, high reliability, and safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

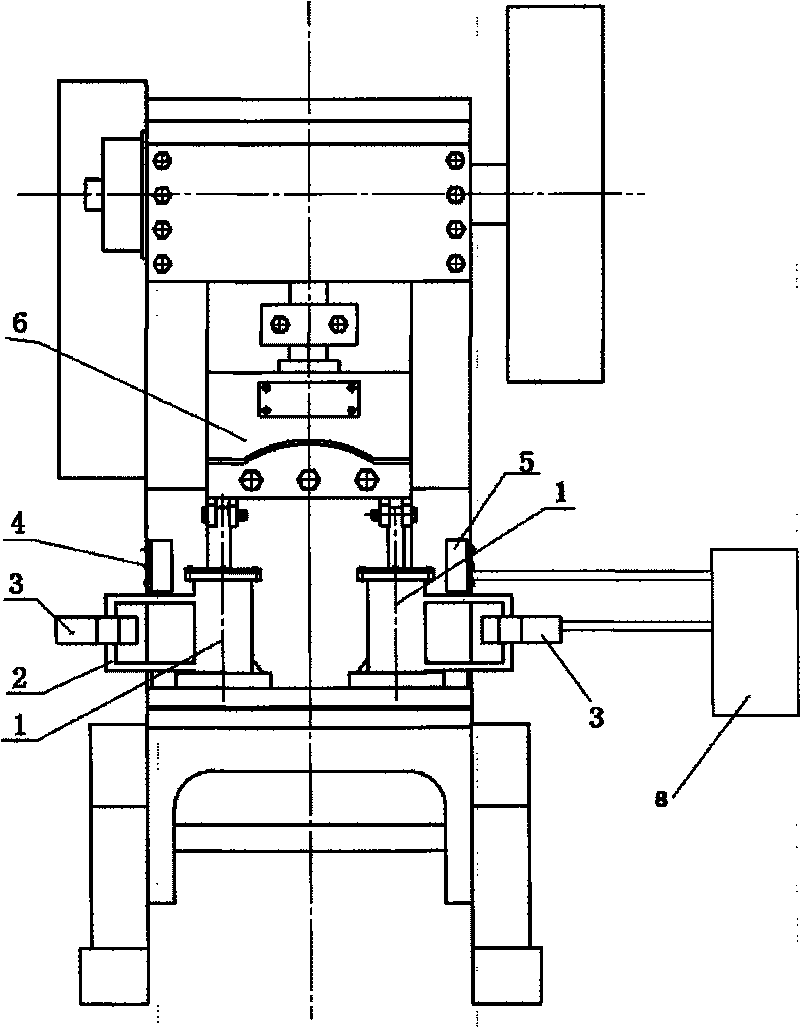

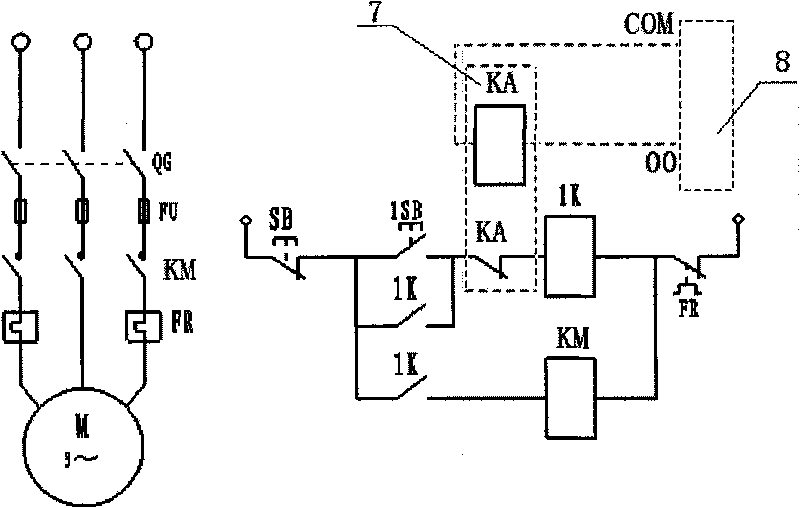

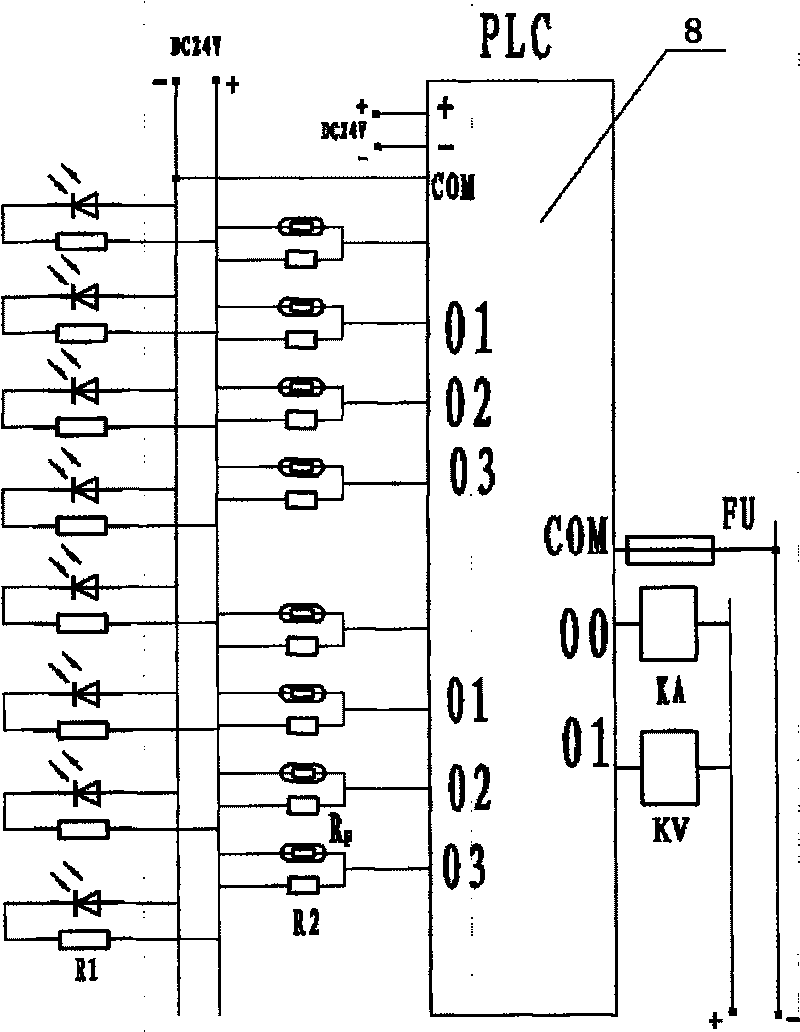

[0032] Implement the punch photoelectric liquid protection device of the present invention, mainly be made up of photoelectric detection part, electric control part, hydraulic device, wherein photoelectric detection part comprises light source 4, photoelectric sensor 5; Electric control part comprises relay 6, and programmable logic controller (PLC) ) 8; the hydraulic brake device includes a hydraulic cylinder 1, an oil circuit 2, and an electromagnetic valve 3.

[0033] The light source 4 and the photoelectric sensor 5 are respectively installed on both sides of the press workbench, the photoelectric sensor 5 is connected with the input end of the programmable logic controller (PLC) 8 of the electrical control part through wires, and an output of the programmable logic controller (PLC) 8 One end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com