Rabbit cage and manufacturing method thereof

A production method and technology of rabbit cages, applied in the field of rabbit cages, can solve the problems of damaged appearance, complicated breeding technology, weak disease resistance, etc., and achieve the effect of avoiding mutual biting, preventing entry, and reasonable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention can be explained in more detail through the following examples, but the present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

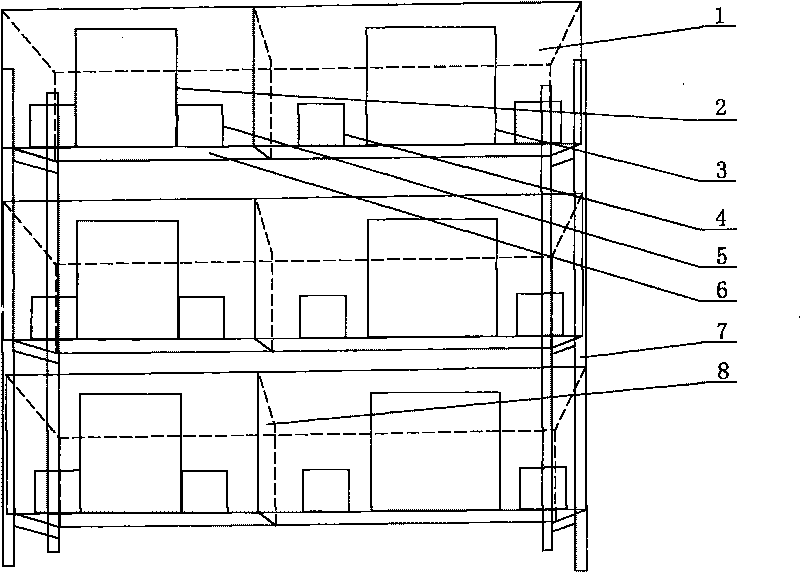

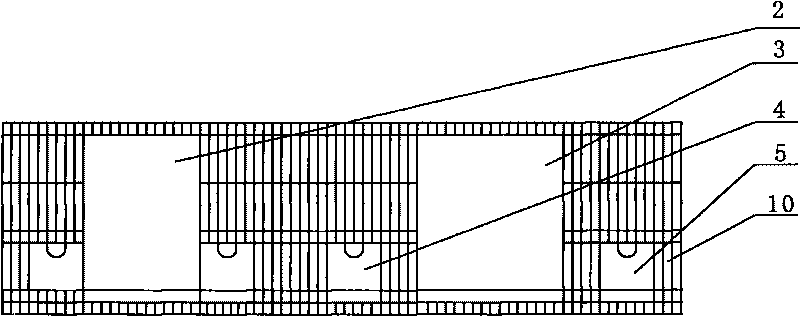

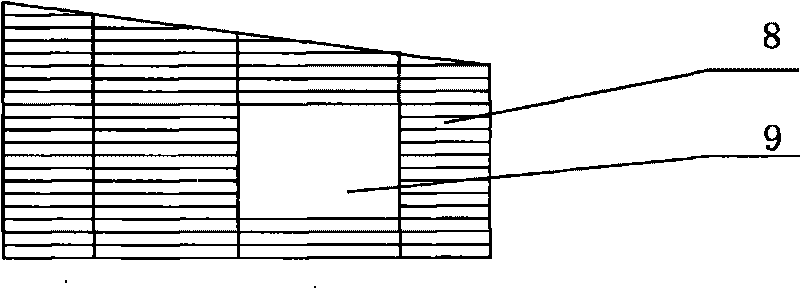

[0029] Such as figure 1 , Figure 4 Shown anti-pika rabbit cage, anti-bite rabbit cage and production method thereof, described anti-pika rabbit cage 1, anti-bite rabbit cage 11 all comprise mesh, support frame 7 and bottom grate 6, and described mesh comprises front net sheet, rear mesh, top mesh, side mesh and spacer; the bottom grate 6 is lapped on the support frame 7, and the rabbit cage formed by the connection of the mesh is arranged on the bottom grate 6, that is, the front mesh, the rear The inner volume part of the mesh supports the bottom grate; figure 2 As shown, at least two cage door holes are provided on the front mesh m10 of the mouse-proof rabbit cage 1, a cage door ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com