Explosion dynamic-load fracturing simulation test device

A simulation test and fracturing technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that large-sized rock samples cannot be accommodated, cannot be used for explosive fracturing tests, etc., and achieve large sample size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

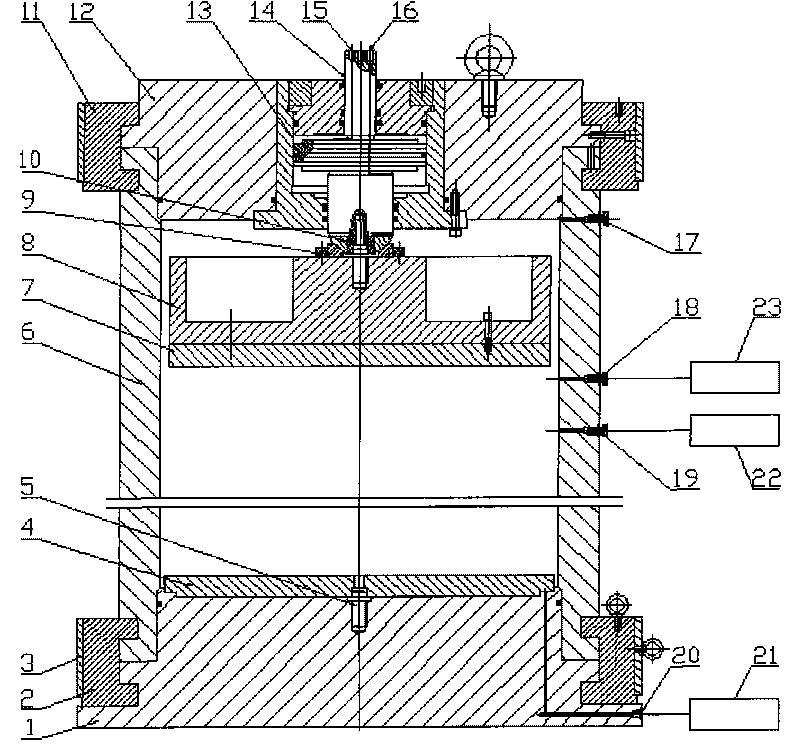

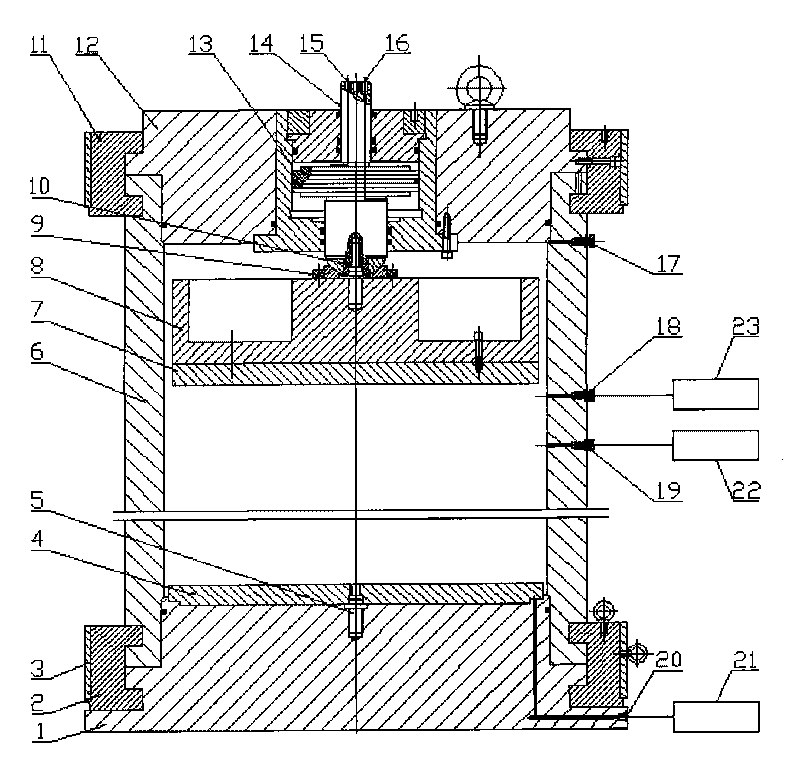

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0012] As shown in the figure, a lower pressure pad 4 is installed on the base 1 with grooves, and an oil inlet hole 20 is opened on the base 1. The oil inlet hole is connected to the hydraulic control system 21 with a high-pressure pipeline, and the base 1 is connected to the cylinder body of the pressure chamber. 6 is connected and fixed by the lower ferrule 2 and the snap ring 3. During the test, the sample is placed on the lower pressure pad 4 and positioned by the positioning pin 5. After the sample is placed, lead the explosive lead out from the lead hole 18 on the pressure chamber cylinder body 6 and connect it to the ignition control system 23. Connected to the data acquisition system 22. Place the upper pressure pad 7 and the upper pressure plate 8 on the sample in sequence. The positioning ring 9 and the positioning pad 10 arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com