Mounting structure for switch cover and small lamp of automobile

A technology of installation structure and switch cover, which is applied in the direction of light installation, vehicle interior lighting device, signal device, etc. It can solve the problems of improper installation, unfavorable disassembly of switch cover or small lamps, and inability to completely eliminate looseness, so as to achieve reliable fixation, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

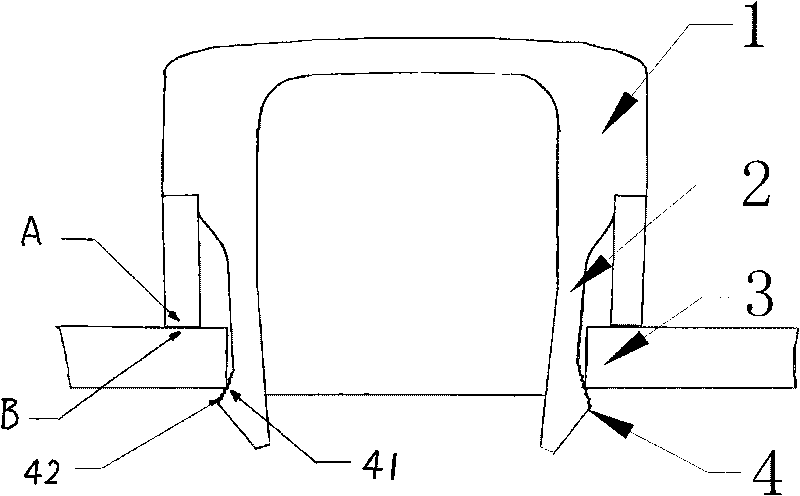

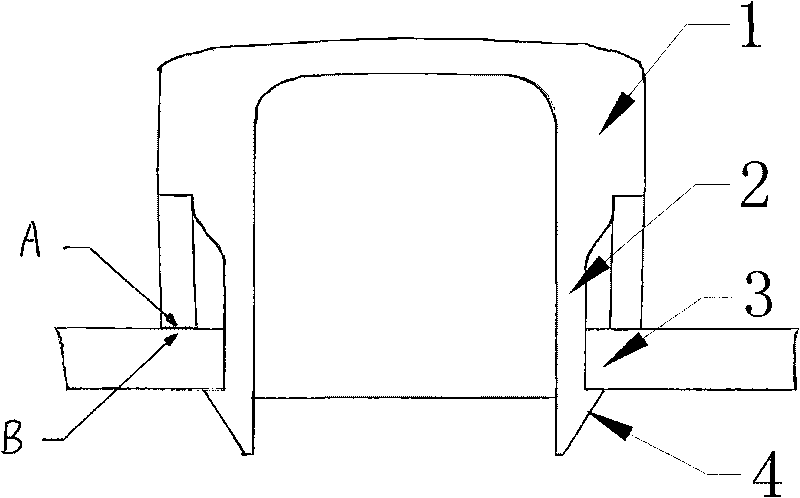

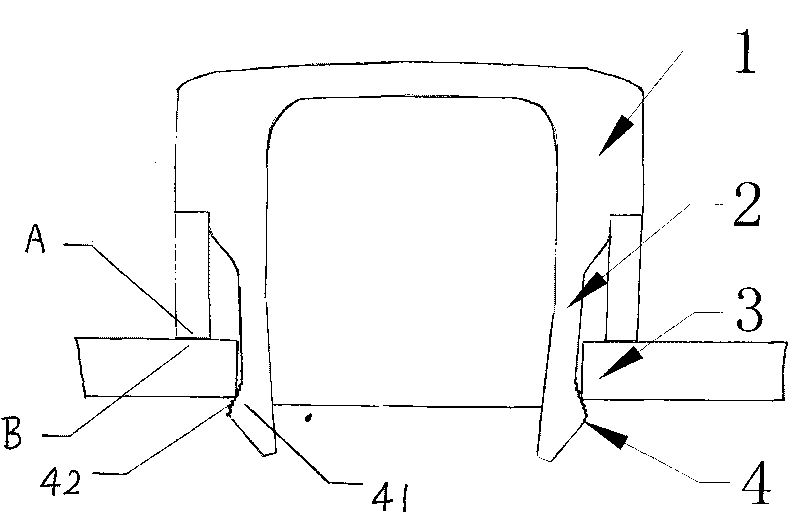

[0013] exist figure 1 In the shown embodiment, the car switch cover or small lamp 1 is installed through the elastic clip arm 2 with barbs on the back and the mounting hole 3 on the car body. Elastic clip arms 2 are evenly and symmetrically distributed along the circumferential direction on the back of the switch cover or small lamp 1, one on the left and one on the left, and a positioning surface A is provided on the back of the switch cover or small lamp 1 to fit with the installation surface B of the mounting hole 3. In this structure, the working surface of the barb 4 at the front end of the elastic arm 2 on the back of the switch cover or the small lamp 1 is designed as a 30° slope surface 41, and the distance between the two symmetrical slope surfaces 41 must be greater than that of the installation hole 3 aperture. At the same time, anti-slip stripes 42 parallel to the installation surface are provided on the slope surface 41 of the barb.

[0014] When installing, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com