Hydraulic driving system for active heave compensation crane

A wave compensation and drive system technology, applied in cranes and other directions, can solve problems such as insufficient response time, poor system dynamic characteristics, and low natural frequency, and achieve the effects of preventing heavy objects from sliding, high precision, and large adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

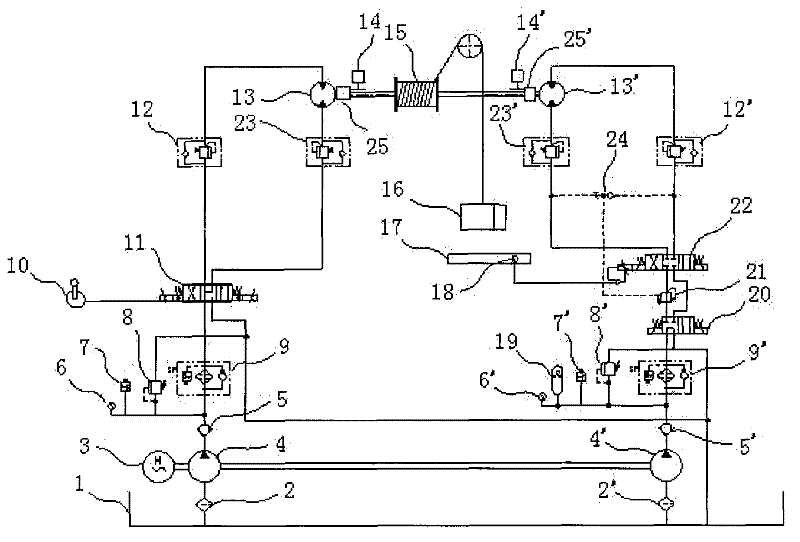

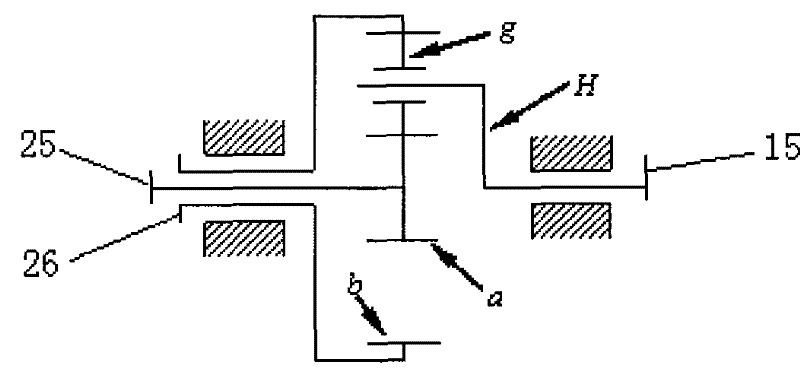

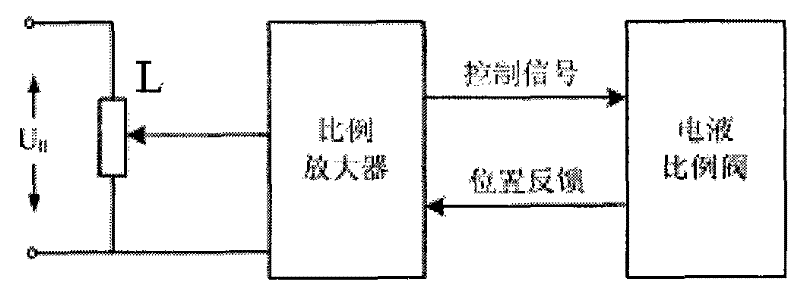

[0016] The structure of the present invention is as figure 1 As shown, it is composed of oil tank 1, lifting oil circuit and compensation oil circuit; lifting oil route suction filter 2, hydraulic pump 4, one-way valve 5, relief valve 8, pressure relay 7, pressure gauge 6, high pressure filter 9 , Electro-hydraulic proportional valve 11, oil inlet and outlet balance valves 12, 23 and hydraulic motor 13 and other hydraulic components, the connection of each component according to the oil flow route is: oil suction filter 2- hydraulic pump 4- one-way valve 5- High-pressure filter 9-electro-hydraulic proportional valve 11-inlet balance valve 12-hydraulic motor 13-outlet balance valve 23, relief valve 8, pressure relay 7, and pressure gauge 6 are installed at the outlet of check valve 5; The compensation oil route is suction filter 2', hydraulic pump 4', one-way valve 5', relief valve 8', pressure relay 7', accumulator 19, pressure gauge 6', high-pressure filter 9', solenoid valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com