Device and method for time sequence open-phase control of three three-phase asynchronous motors

A three-phase asynchronous, motor technology, applied in the direction of controlling multiple AC motors, can solve the problems of new system failure, construction difficulty, construction cost increase, etc., to reduce equipment failure rate, save material costs and construction costs, improve Effects of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

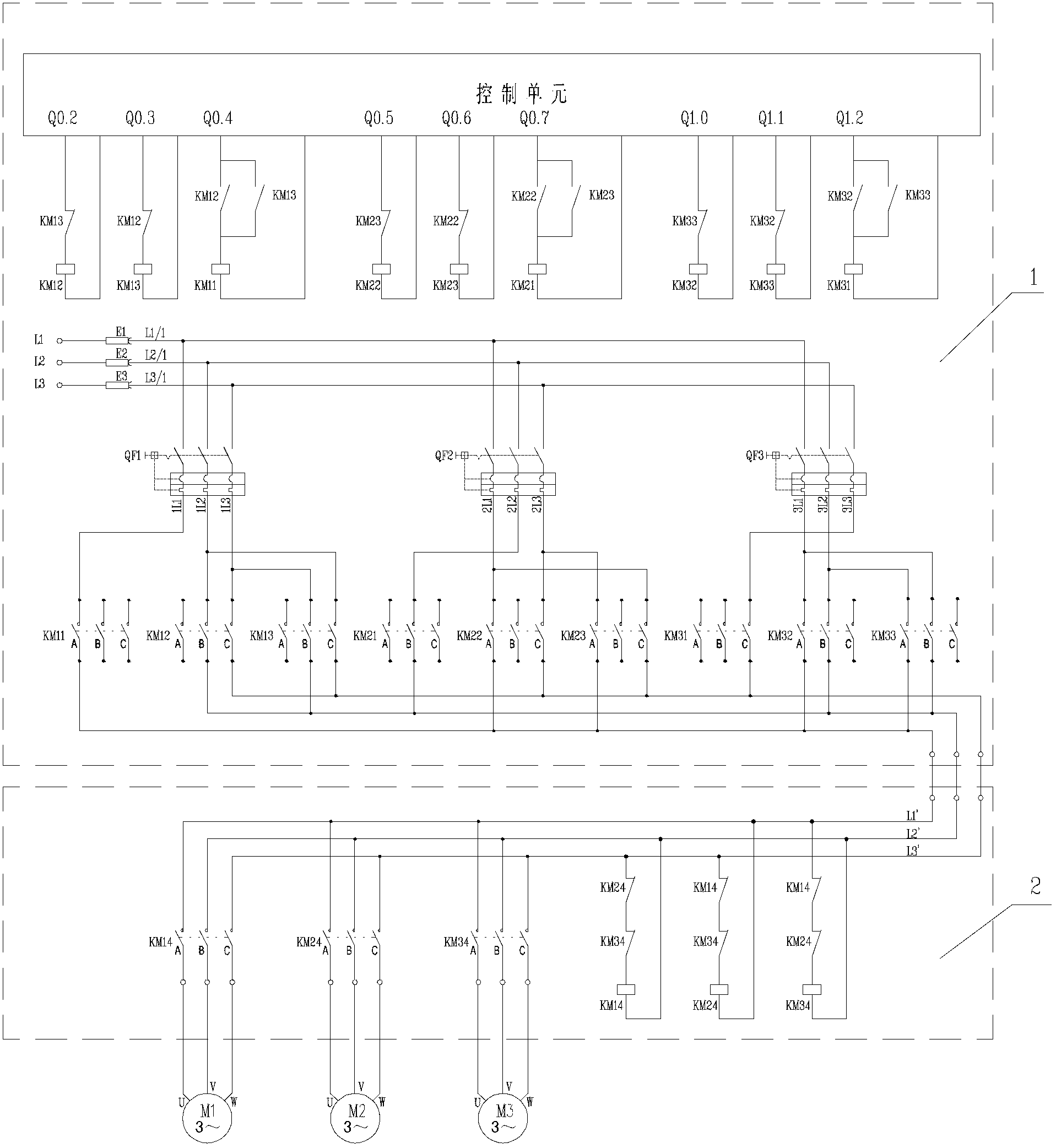

[0034] The device of the present invention controls three three-phase asynchronous motors with time-sequential phase loss, and is composed of a main control box 1, a sub-control box 2 and a three-phase asynchronous motor M.

[0035] The main control box 1 includes a control unit, a fuse E, an automatic switch QF, a contactor KM and a three-phase three-wire system power line L-L.

[0036] The auxiliary control box 2 includes an AC contactor KM and a three-phase three-wire power line L-L.

[0037]Three sets of fuses E1, E2, and E3 in the main control box 1 are sequentially connected to the live wire inlet sides L1, L2, and L3 of the three-phase three-wire system power line, and the live wires at the output terminals of fuses E1, E2, and E3 are L1 / 1, L2 / 1, L3 / 1; automatic switch QF1, automatic switch QF2, automatic switch QF3 use wires and connect to three-phase live wires L1 / 1, L2 / 1, L3 / 1; automatic switch QF1 output line is a three-phase power line 1L1, 1L2, 1L3; automatic swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com