Time sequence single-phase-control three-unit three-phase asynchronous motor device and method thereof

A three-phase asynchronous, electric motor technology, applied in the direction of controlling multiple AC motors, can solve the problems of construction difficulty and cost increase, new system failures, etc., to save material costs and construction costs, reduce equipment failure rate, and improve operation conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

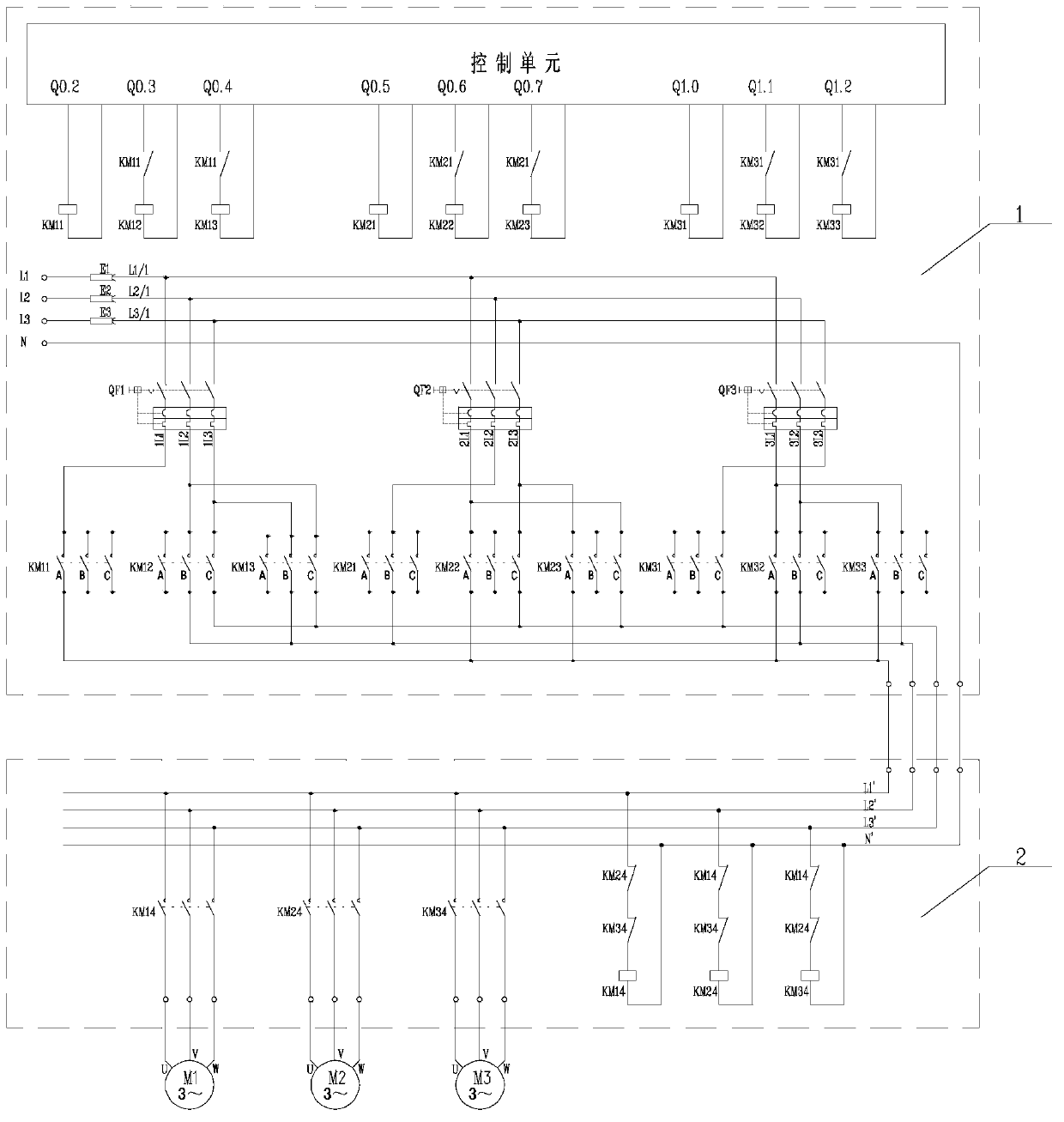

[0035] The time-sequential single-phase control device for three three-phase asynchronous motors of the present invention is composed of a main control box 1, an auxiliary control box 2 and a three-phase asynchronous motor M.

[0036] The main control box 1 includes a control unit, a fuse E, an automatic switch QF, a contactor KM and a three-phase four-wire power line.

[0037] The auxiliary control box 2 includes a contactor KM and a three-phase four-wire system power line.

[0038]The three fuses E1, E2 and E3 in the main control box 1 are connected to the incoming side of the live wires L1, L2 and L3 of the three-phase four-wire system power line, and the live wires at the output terminals of the three fuses E1, E2 and E3 are in turn L1 / 1, L2 / 1, L3 / 1; automatic switches QF1, QF2, QF3 are respectively connected to three-phase live wires L1 / 1, L2 / 1, L3 / 1 through wires; the output line of automatic switch QF1 is a three-phase power line 1L1, 1L2, 1L3; automatic switch QF2 ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com