Assembling and testing device and method thereof

A technology for assembly testing and lens modules, which is applied in testing optical performance, optics, instruments, etc., can solve problems affecting the efficiency of lens module assembly and testing, and achieve the effect of saving eccentricity adjustment time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

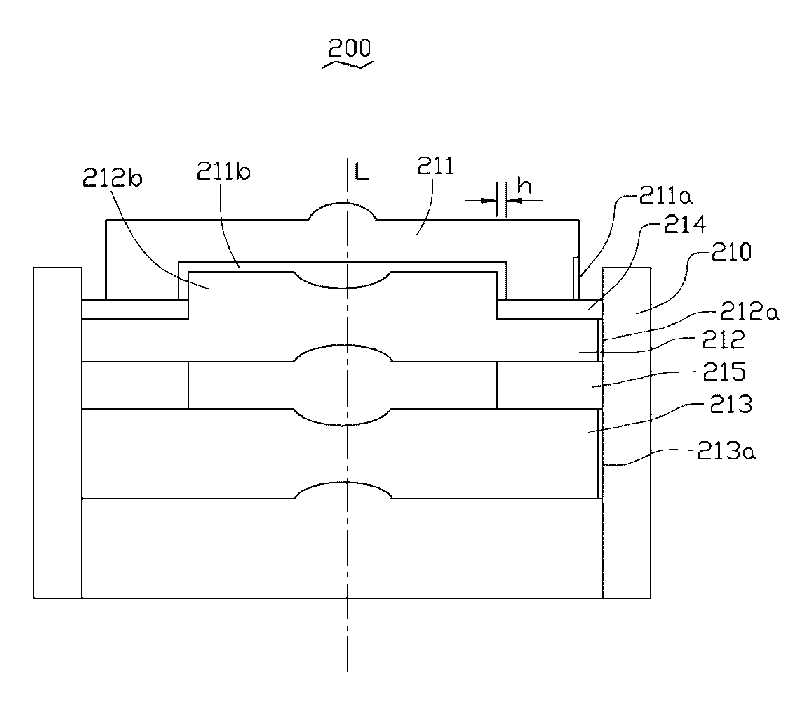

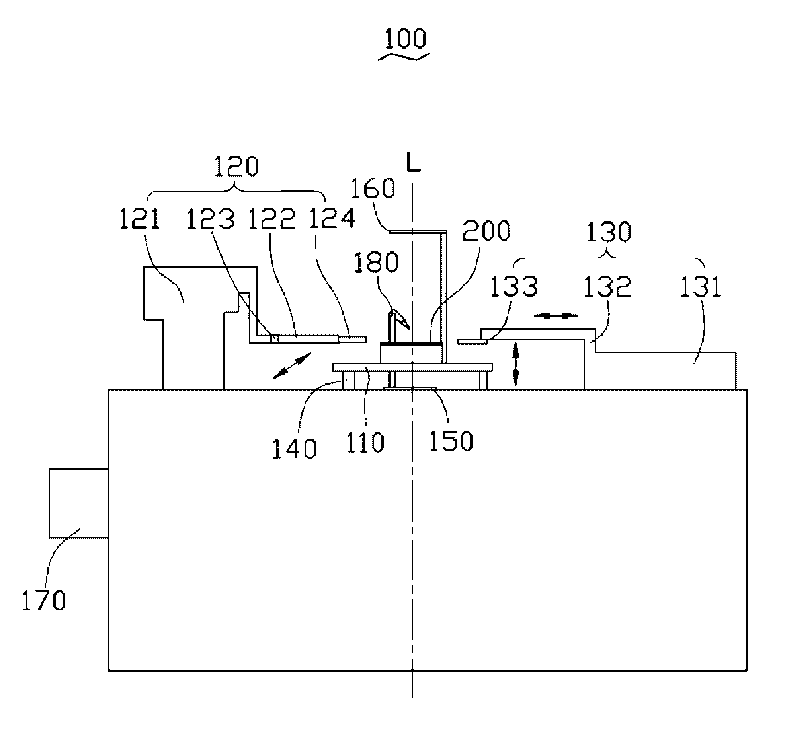

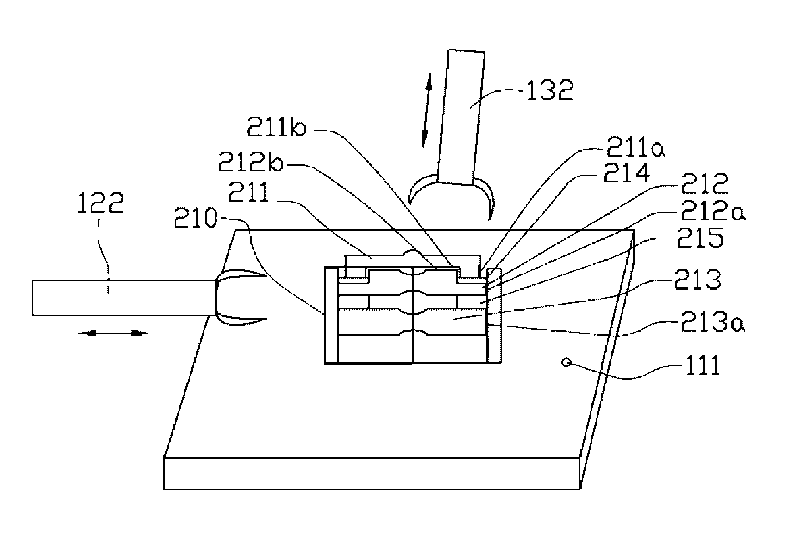

[0014] see figure 1 and figure 2 The lens module 200 tested by the assembled testing device 100 provided by the present invention includes a lens barrel 210 , a first lens 211 , a second lens 212 , a third lens 213 , a first spacer ring 214 and a second spacer ring 215 .

[0015] The first lens 211 , the first spacer ring 214 , the second lens 212 , the second spacer ring 215 and the third lens 213 are sequentially accommodated in the lens barrel 210 from the object side to the image side. The first lens 211 , the second lens 212 and the third lens 213 are all formed by injection molding, and the edges of the first lens 211 , the second lens 212 and the third lens 213 all have gate traces 211 a , 212 a and 213 a. The gate traces 211a, 212a and 213a all point to the same radial direction. The first lens 211 can move radially relative to the second lens 212...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com