Belt dropping detection method for motor of drum washing machine or washing-drying integrated machine

A technology of a drum washing machine and a detection method is applied to other washing machines, control devices of washing machines, washing devices, etc., and can solve problems such as inability to spin dry, hidden dangers, and wrinkles on clothes, and achieve the effect of eliminating hidden dangers and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

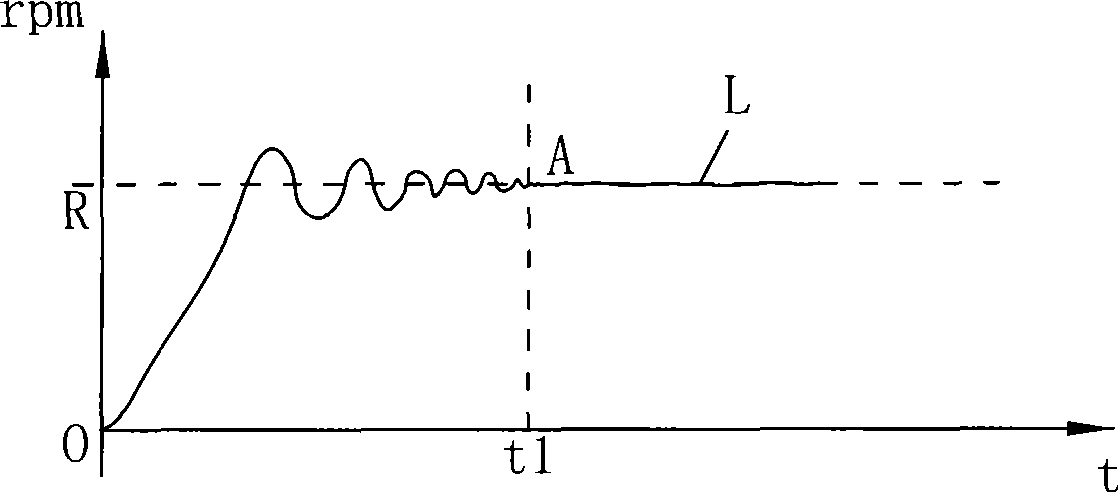

[0020] According to the present invention, the method for detecting motor belt shedding of drum washing machine and washer-dryer integrated machine. After starting to work, the main control board CPU of the washing machine sends pulses to adjust the conduction angle of the thyristor so that the drive motor runs at the set speed. The conduction angle of the thyristor during the rotation of the motor is detected to determine the relationship between the motor and the belt, so as to determine whether the motor and the belt are connected normally.

[0021] Generally speaking, after the drum washing machine or the washer-dryer works, the motor will start to rotate through a process of unstable speed, such as figure 1 As shown, the abscissa t represents the rotation time of the motor, the ordinate rpm represents the motor speed, and the curve represents the speed adjustment process when the motor rotates. After a period of operation t1, the motor speed begins to stabilize, and the speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com