Hafu joint

A technology of half joints and occlusal teeth, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of poor high pressure resistance and water hammer resistance, poor sealing performance of half joints, etc. Achieve the effect of improving high pressure resistance and water hammer resistance, improving sealing performance and increasing installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

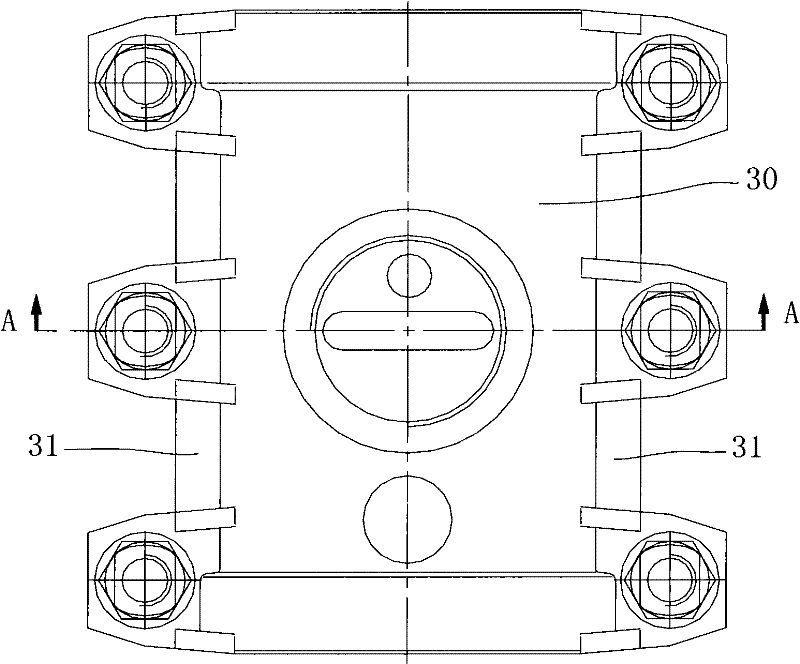

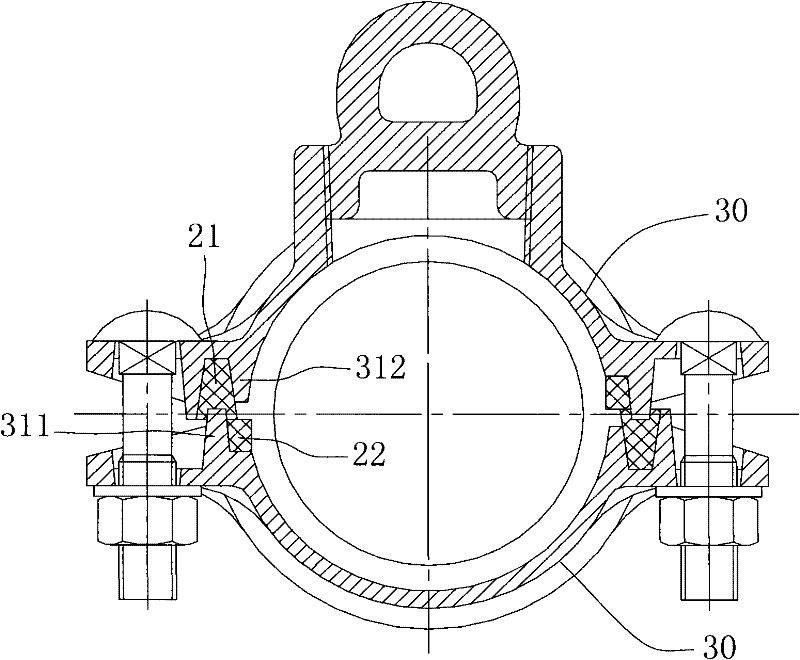

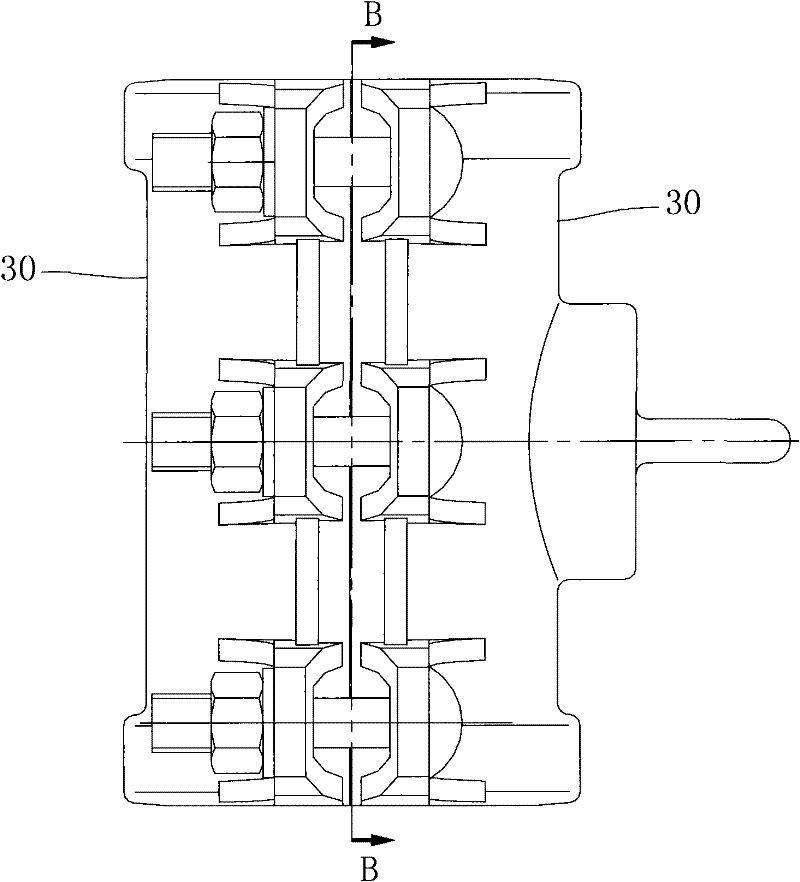

[0016] like Figure 1~5 As shown, a Huff joint includes two oppositely installed housings 30, and both sides of the housing 30 along the axial direction are provided with outwardly extending flanges 31, and the two flanges 31 are The occlusal teeth 311 and the occlusal bed 312 are respectively provided, and the two shells 30 are connected together by the occlusal teeth 311 and the occlusal beds 312 interlocking.

[0017] The shapes of the two housings 30 are the same, that is, each housing 30 is provided with two flanges 31, one flange 31 is provided with occlusal teeth 311, and the other flange 31 is provided with an occlusal bed 312, such as figure 2 , 4 , 5 shown. During construction and installation, the two housings 30 are installed opposite to each other, and the occlusal teeth 311 of one housing 30 are engaged with the occlusal bed 312 of the other housing 30, and then the bolts are sequentially passed through the two housings 30 opposite to each other. Flange edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com