Adherent buckle woven fabric

A fabric and gluing technology, applied in the direction of fabrics, textiles, fasteners, etc., can solve the problems of no consistent direction, poor hooking ability, and easy hooking to other clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

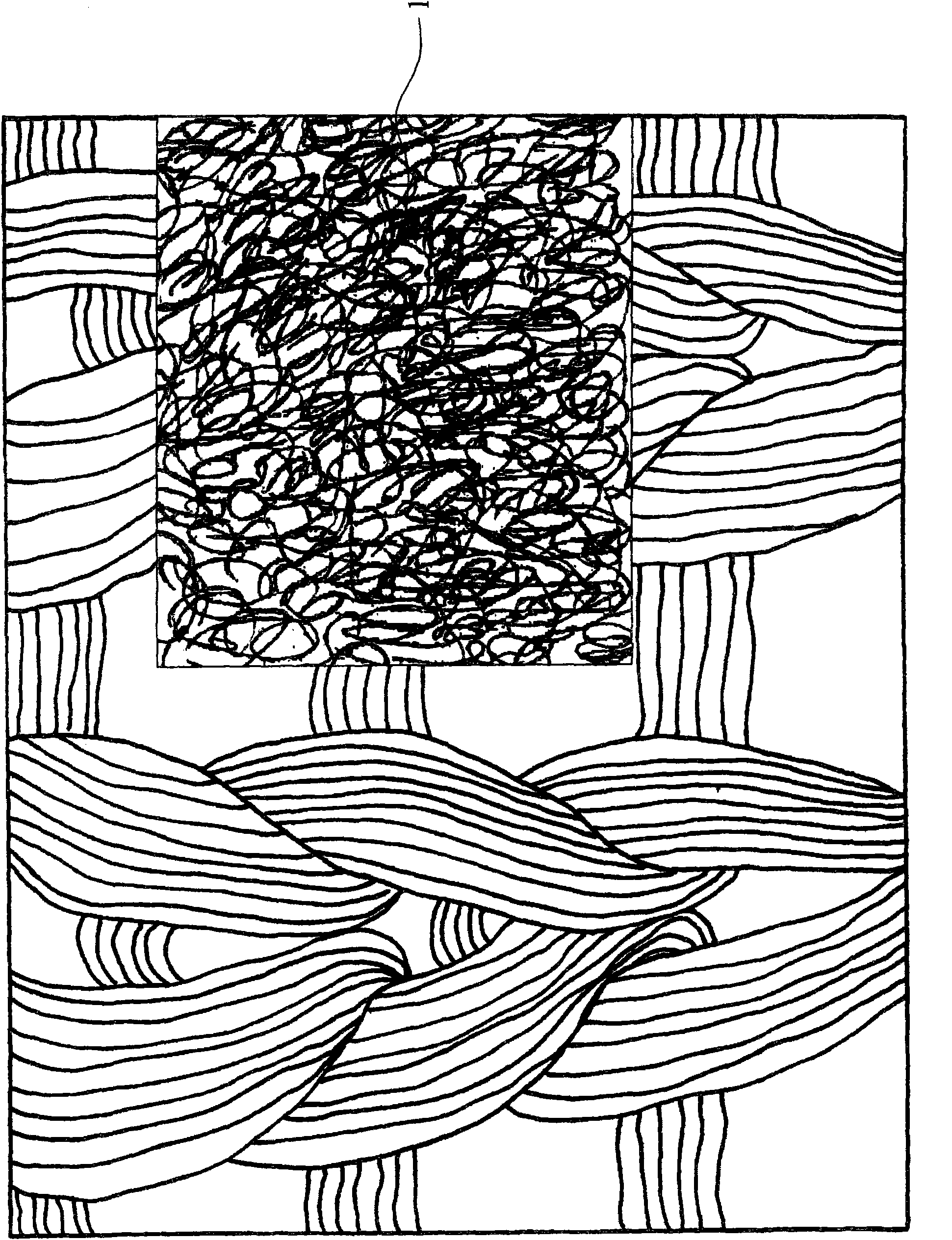

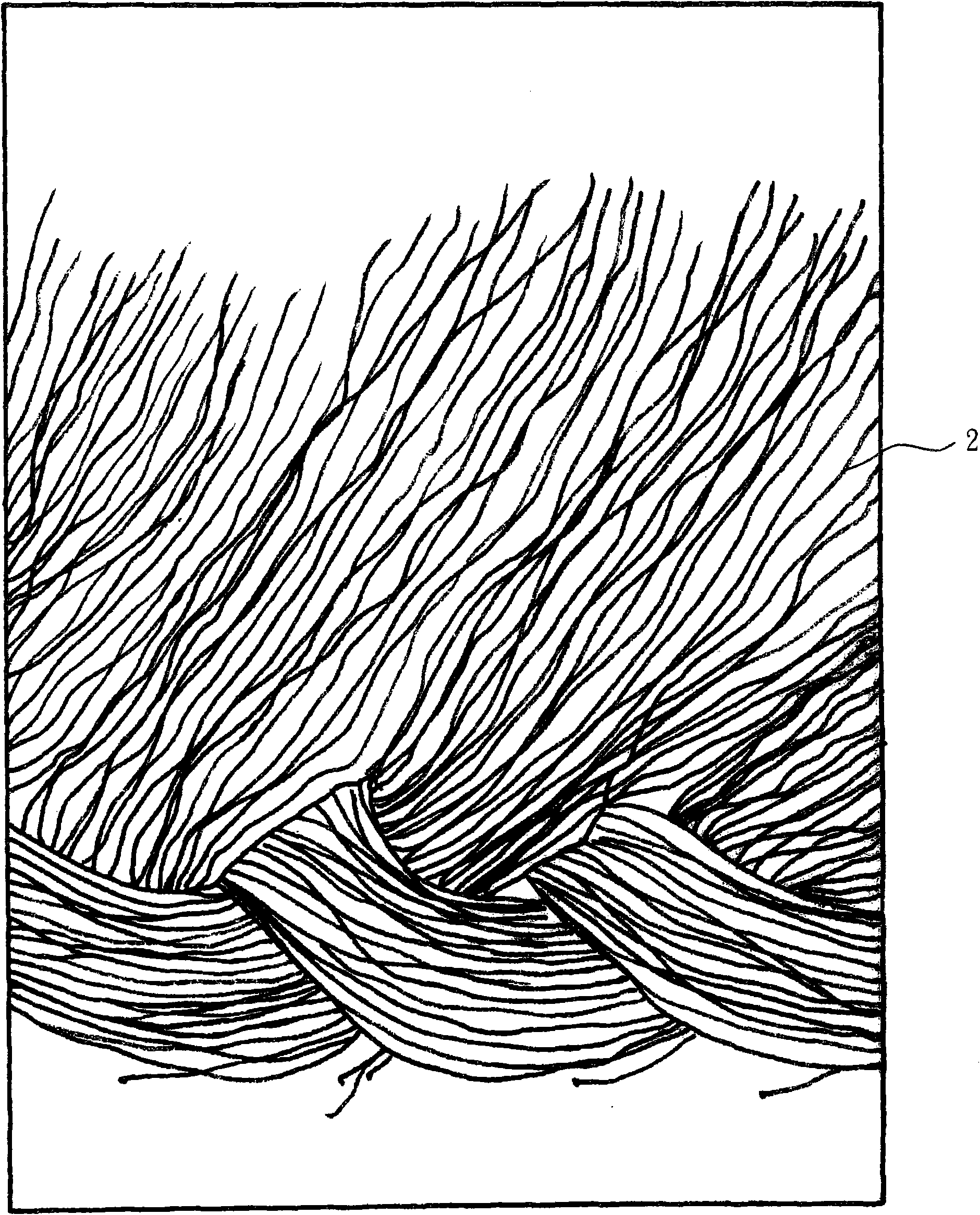

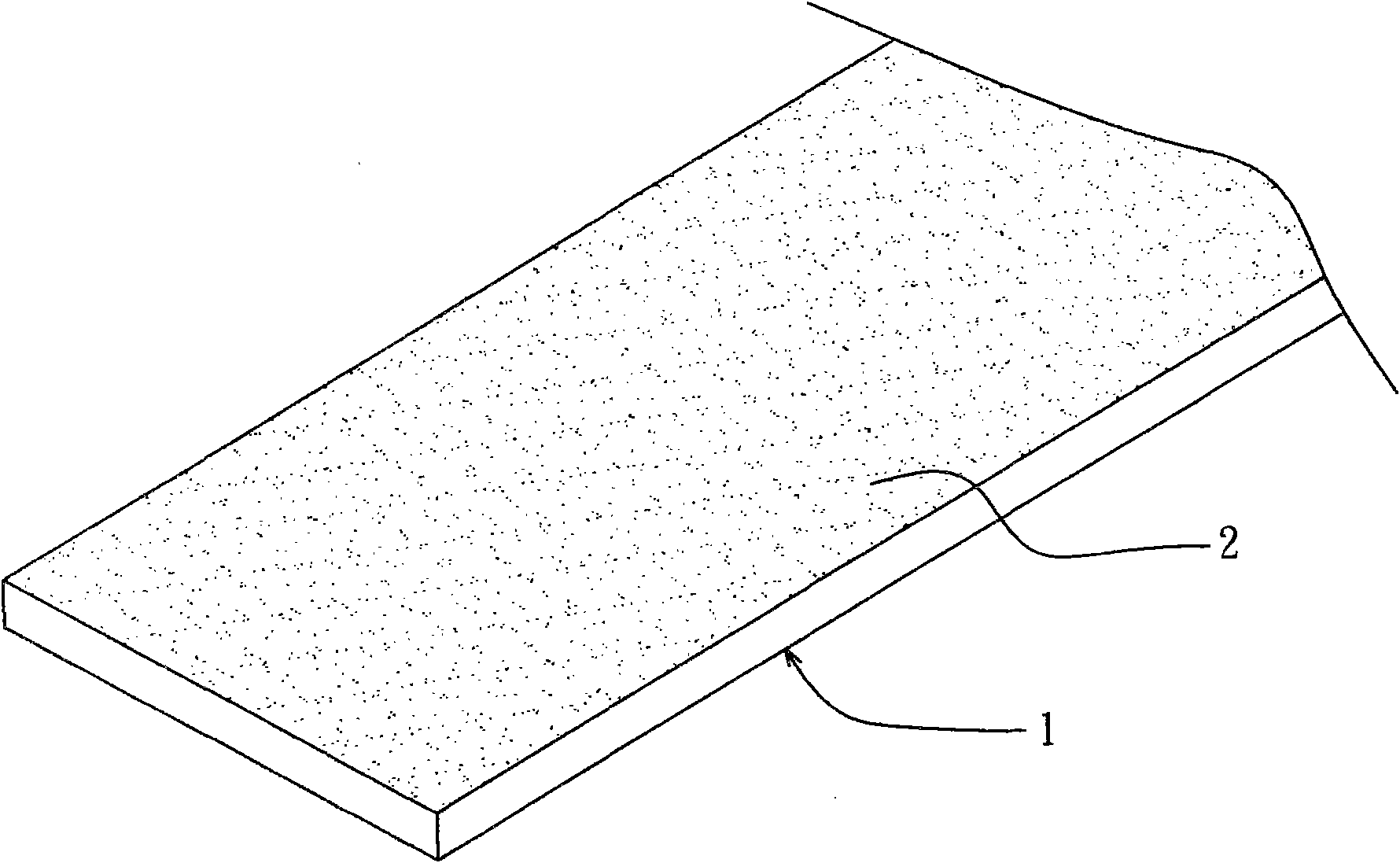

[0017] Such as figure 1 and figure 2 As shown, basically, the Velcro fabric of the present invention is composed of a loop fabric 1 and a hook fabric 2 .

[0018] see figure 1 , The loop fabric 1 is to form a single fiber buckle that is itself dense and loose between two interweaving points of the yarn, and its function is like the loop (loop) of a known hook and loop fastener. When this loop fabric 1 is implemented, it is better to be the superfine fiber of composite spinning, and described superfine fiber refers to that the denier number of fiber is below 1; And the method for making of superfine fiber is very mature technology, such as figure 1 As shown, the general adopter is to compound and spin two kinds of polymer fibers of different materials to form composite filaments, and then separate them (generally called fiber opening) to obtain ultrafine fibers. Therefore, the loop fabric 1 of the present invention is woven with superfine fiber yarns, and then subjected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com