Sticky buckle fabric

A fabric and sticky button technology, which is applied in the direction of fabric, textile, fasteners, etc., can solve problems such as poor hooking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

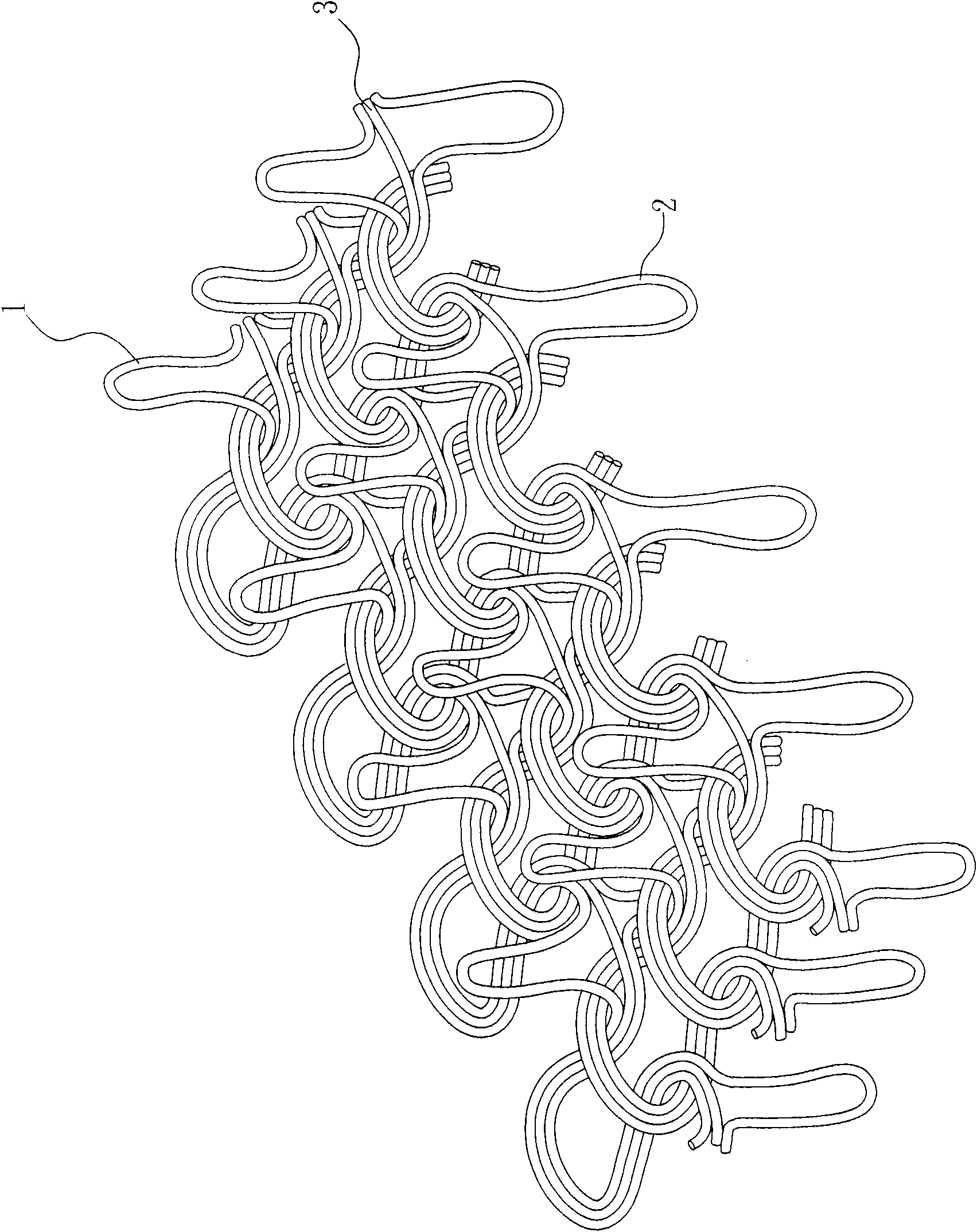

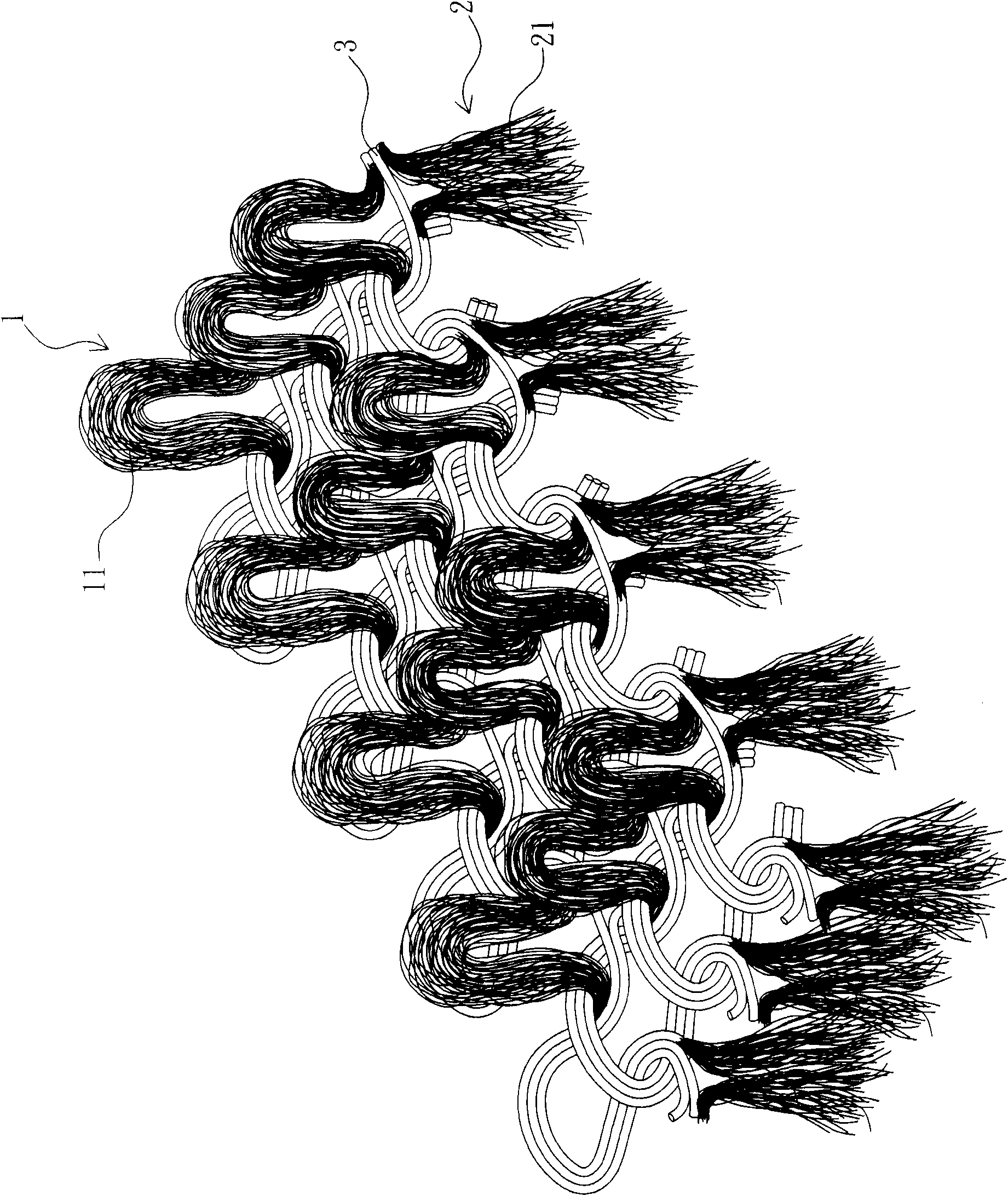

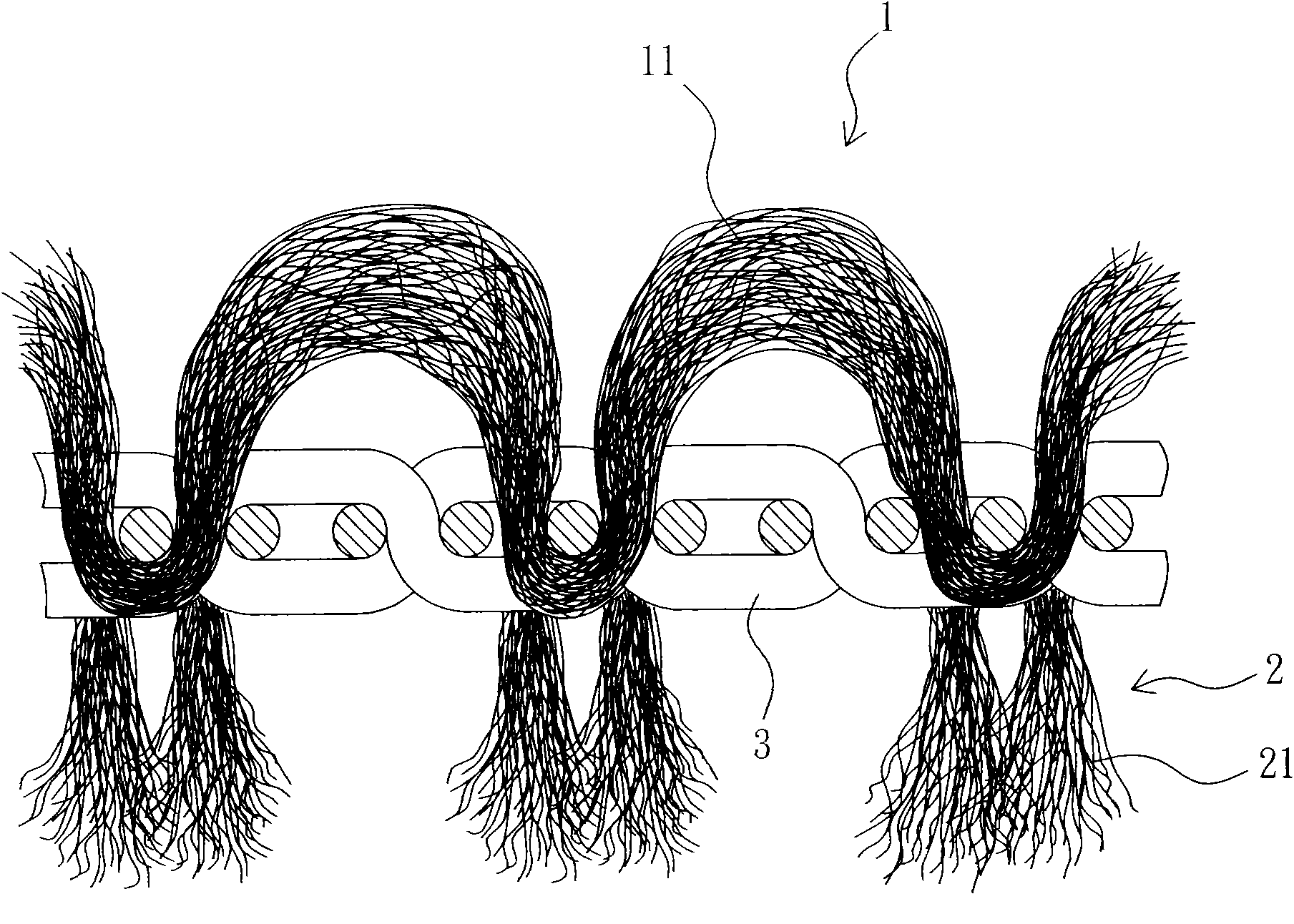

[0020] In order to further disclose the specific technical content of the present invention, first please refer to the drawings, wherein, figure 1 It is a partially enlarged schematic diagram of the double-faced loop knitted fabric of the present invention without fiber opening treatment of the ring structure and unshearing treatment of the hook structure, figure 2 It is a partially enlarged schematic diagram of the double-faced loop knitted fabric of the present invention with the loop tissue treated by fiber opening and the hook tissue processed by shearing, image 3 It is a schematic diagram of different faces of the same woven fabric weaving the ring structure and the hook structure in the present invention, Figure 4 It is a schematic diagram of different positions of the loop weaving and the hook weaving on the same side of the fabric of the same shuttle for the present invention, Figure 5 It is a schematic diagram of two different woven fabrics that weave the loop st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com