Automatic sizing machine

A glue applicator, automatic technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of uneven dispensing, difficult quality assurance, low production efficiency, etc., to avoid waste, improve production efficiency, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

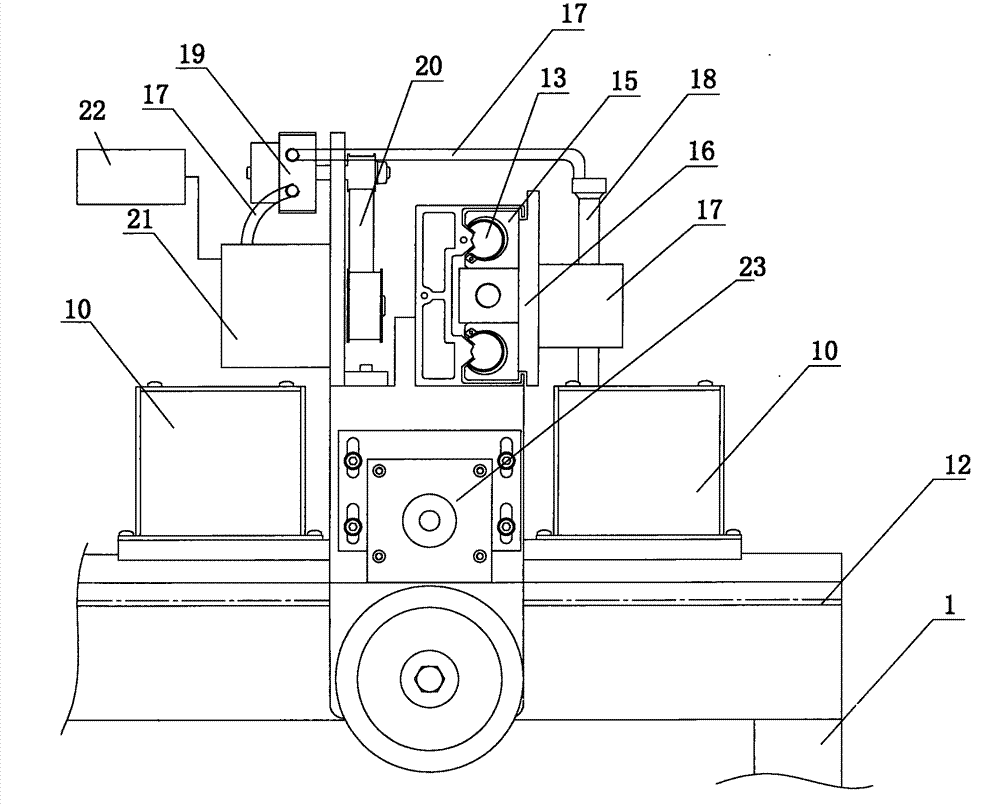

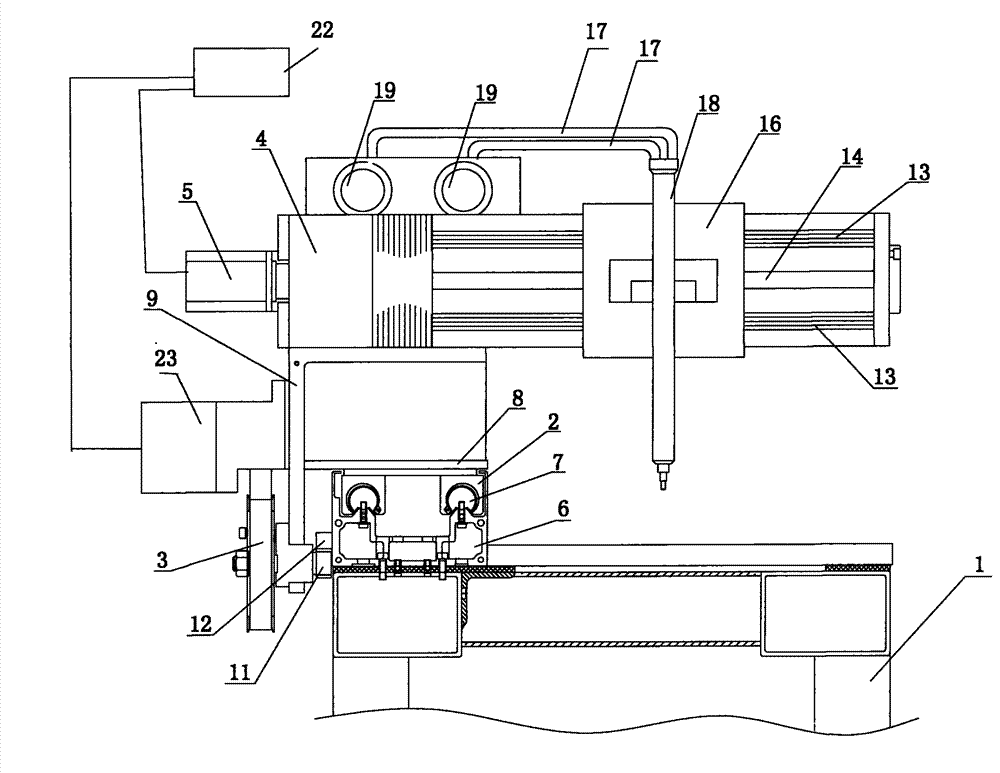

[0024] Automatic sizing machine structure of the present invention is as Figure 1 ~ Figure 2 As shown, it includes a Y-axis sliding mechanism that can slide along the glue application direction, a cantilever mechanism, a control device 22 for controlling automatic glue feeding and a Y-axis sliding mechanism, an automatic glue feeding system and a glue mixing and sizing device 18; the cantilever mechanism includes Z-axis column frame 9, X-axis straight cantilever 4; Y-axis sliding mechanism includes Y-axis guide rail seat 6 fixed on the gluing table 1, Y-axis guide rail 7 fixed on the Y-axis guide rail seat 6, clamped on the Y-axis The Y-axis sliding seat 2 and the Y-axis sliding driving device 3 on the guide rail 7; the Y-axis sliding driving device 23 (a commonly used stepping motor can be used) is connected with the large gear 3 fixed on the Z-axis column frame 9 through a synchronous belt; The large gear 3 drives the secondary pinion 11 to mesh with the rack 12 fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com