Semiconductor packaging structure and heat radiating fin thereof

A technology for semiconductors and heat sinks, which is applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., and can solve problems such as package structure damage and package structure that cannot achieve the expected heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

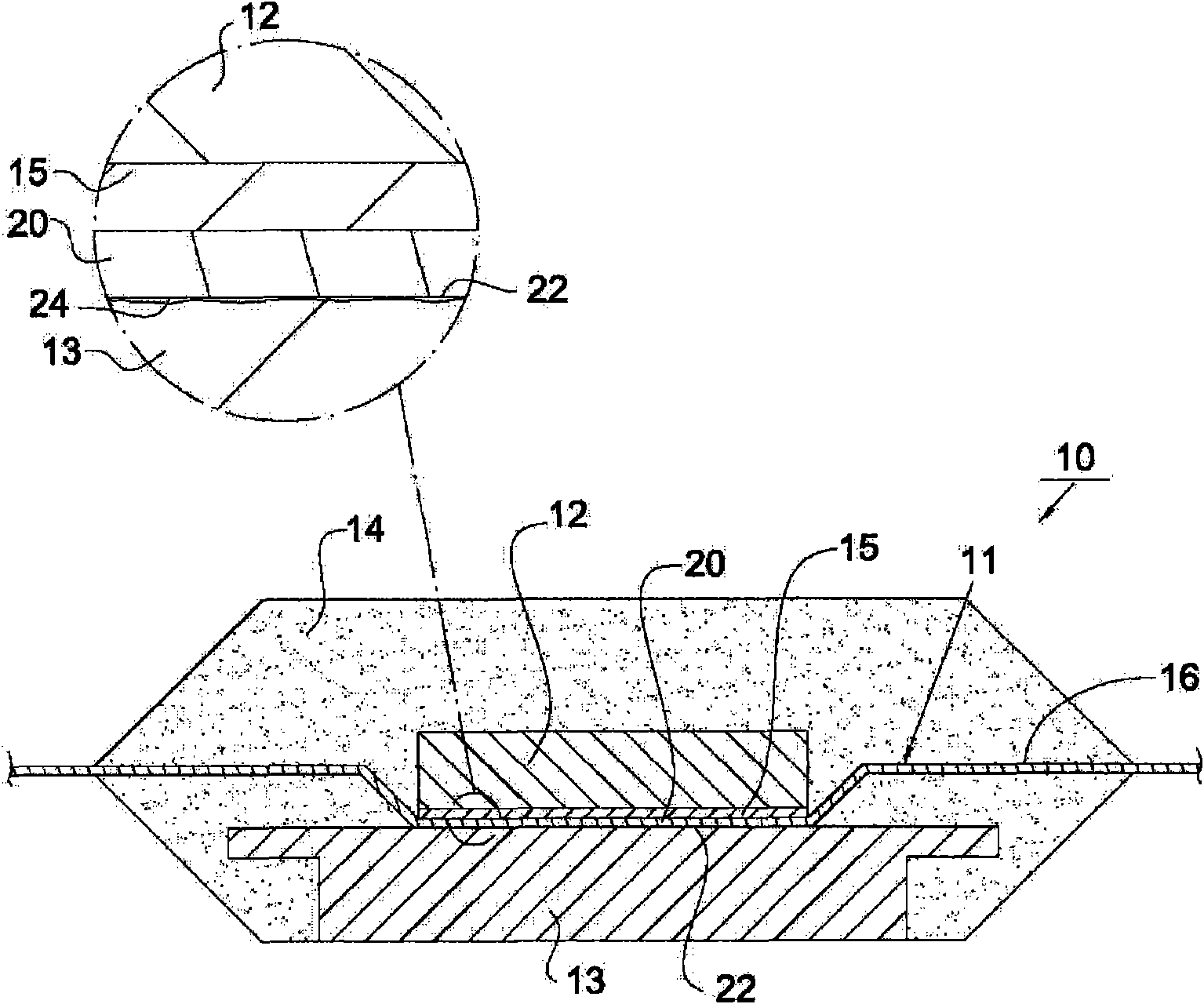

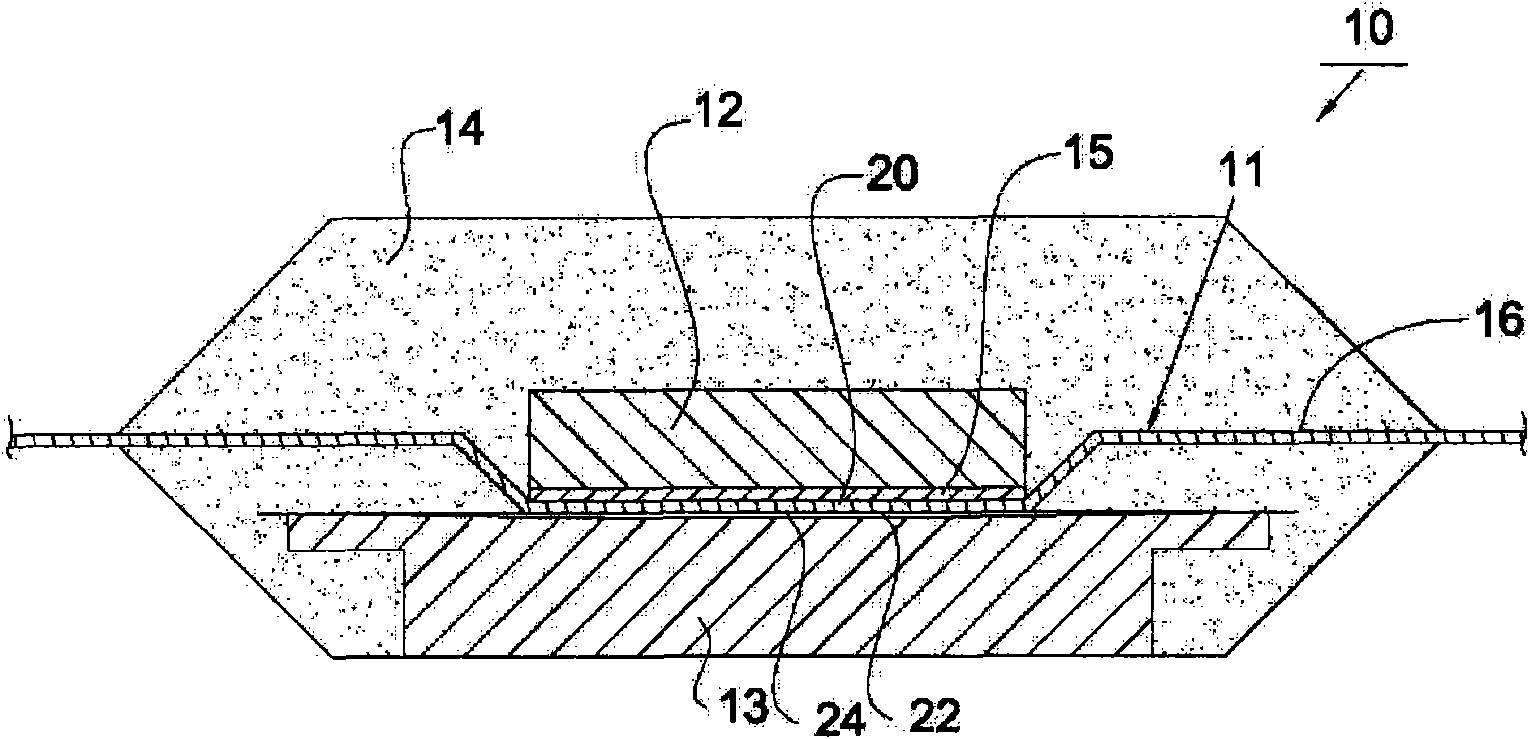

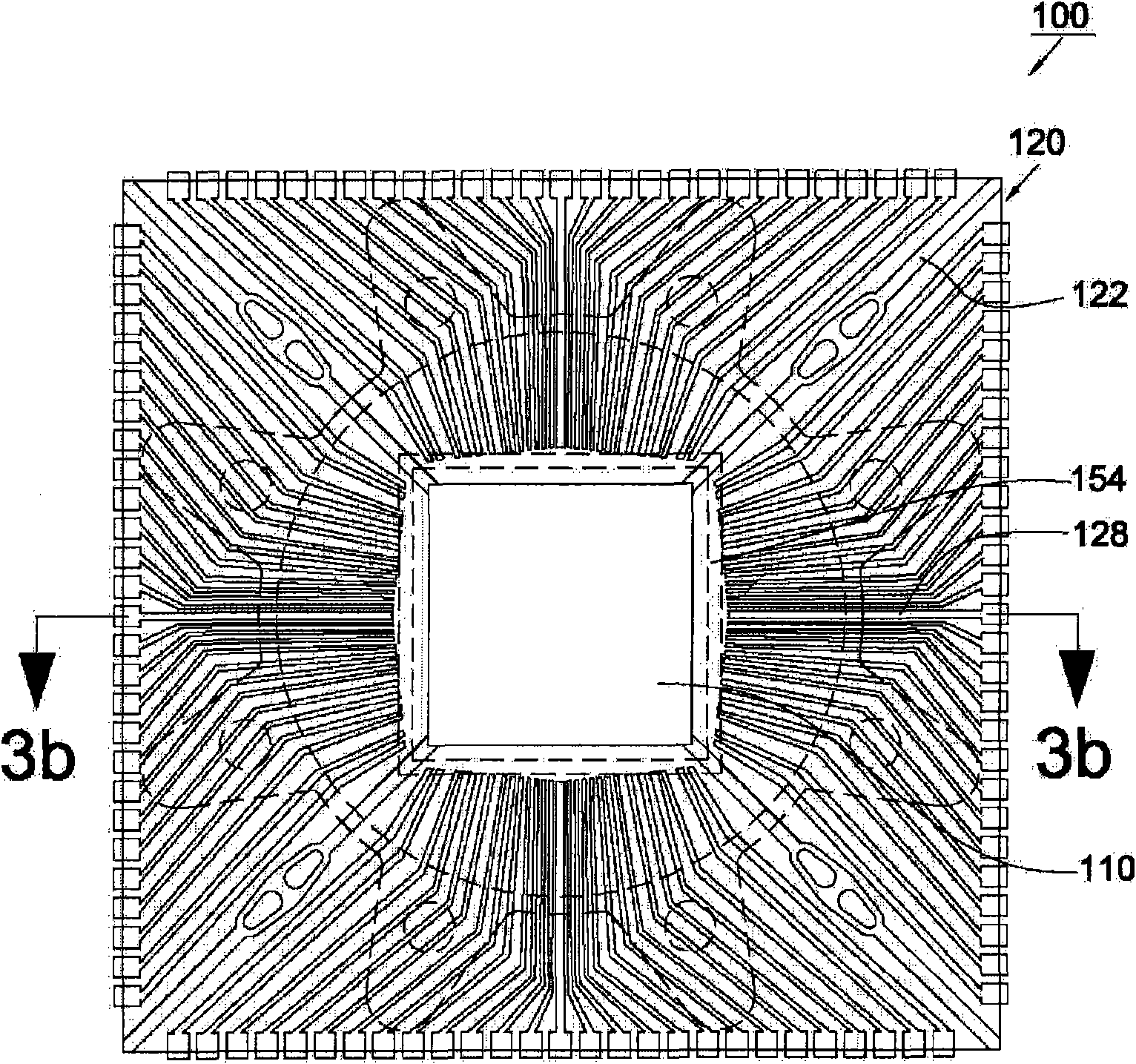

[0030] refer to Figure 3a and 3b , which shows a semiconductor package structure 100 according to an embodiment of the present invention. The semiconductor package structure 100 includes a chip 110 , a lead frame 120 , a heat sink 150 and an encapsulant 160 . The lead frame 120 includes four supporting ribs 122 and a chip holder 124 , the supporting rib 122 is connected to a corner of the chip holder 124 , and the chip holder 124 is used for carrying the chip 110 . The chip 110 is fixed on the upper surface 126 of the chip holder 124 of the lead frame 120 through the adhesive 112 , and is electrically connected to the pins 128 of the lead frame 120 through bonding wires (not shown). The heat sink 150 is attached to the lower surface 130 of the chip holder 124 for conducting the heat generated by the chip 110 to the outside. The heat sink 150 includes a body 152 and an annular strip-shaped protrusion 154 . The body 152 has an upper surface 156 and a lower surface 158 , wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com