Precise-amount seed dibbing machine

A seeding machine and precision technology, which is applied to the machinery, planting methods and applications of interval quantitative seeding, can solve the problems of low work efficiency, time-consuming and laborious, inaccurate seeding, etc., and achieve high work efficiency and prevent emptying. The effect of increasing the acupoint rate and high precision rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

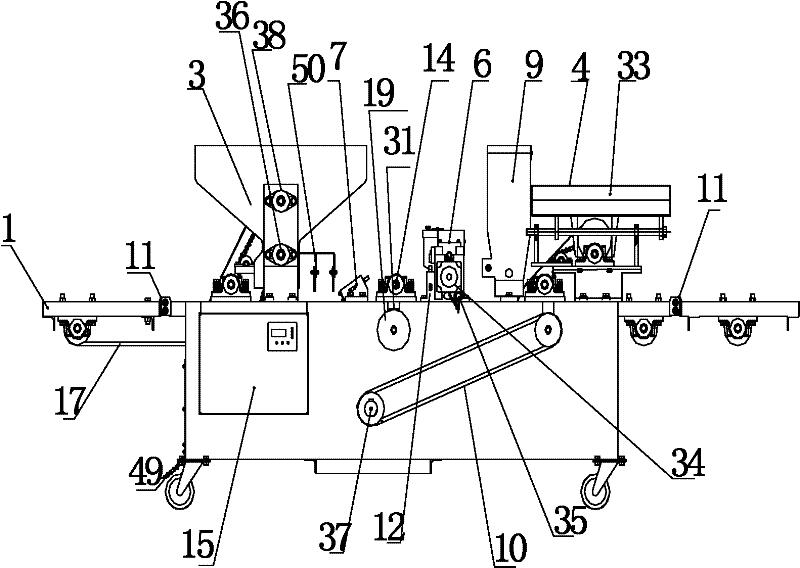

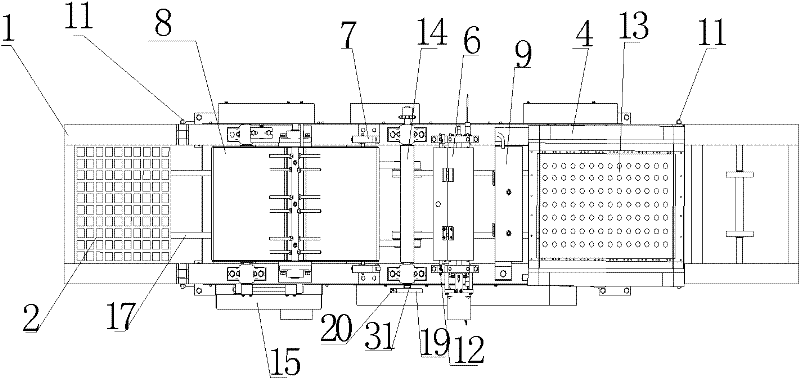

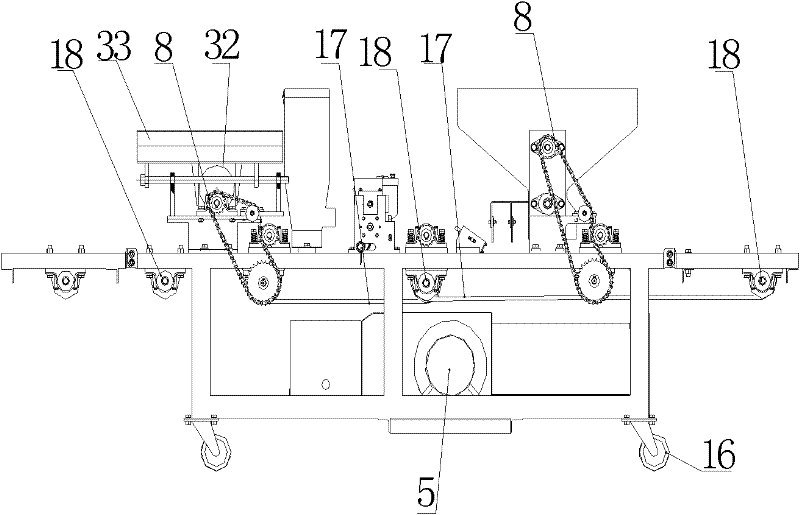

[0034] like figure 1 , figure 2 , image 3 , Figure 4 , which is a schematic diagram of the structure of the precision spotting machine of the present invention, including a controller 15, a frame 1, a motor 5, a transmission assembly 8 arranged on the frame, a covering bucket 3, a spotting assembly 6, and a soil covering assembly 4 , a synchronization unit, a water spray assembly 9, and two scrapers 50 for scraping off excess substrate on the seedling raising tray 2;

[0035] The controller is used to control the rotation speed of the stepping motor. The upper end of the controller 15 is movably connected to the side of the frame through hinges; the two ends of the frame are connected to the middle of the frame through hinges and bolts, which can be flattened or lowered at any time for easy transportation. ; There are moving wheels under the frame;

[0036] The motor 5 drives the transmission assembly 8 to rotate;

[0037]The transmission assembly 8 can drive the seedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com