Method for non-destructive measurement and calculation of casting length of anchor bolt

A bolt and attenuation coefficient technology, applied in measuring devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve problems such as unclear technical solutions, complex guided waves, and large frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

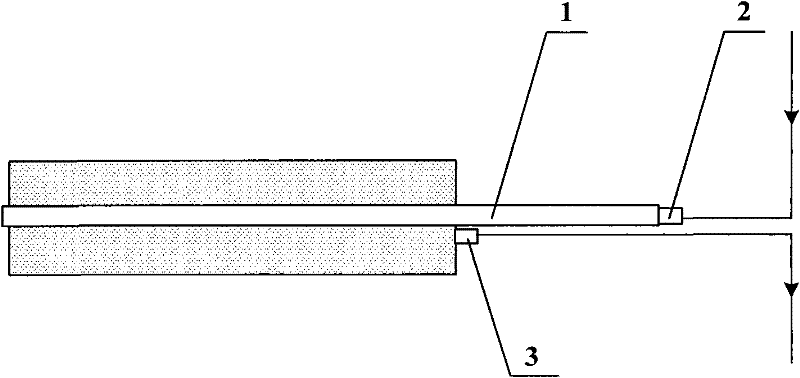

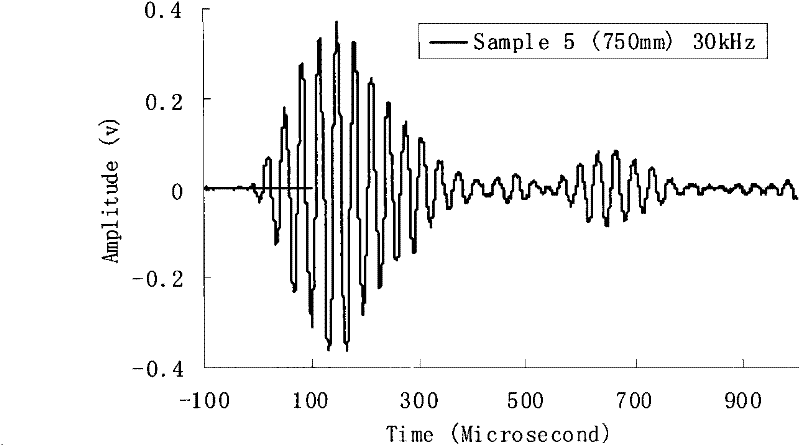

[0086] like figure 1 , figure 2 , image 3 shown.

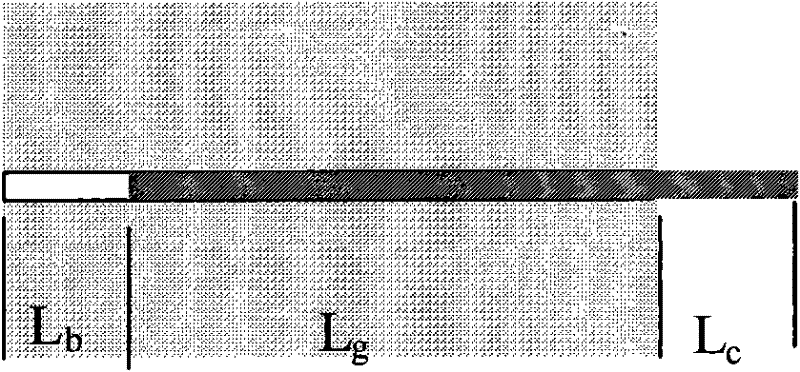

[0087] Select three anchor rods with the same material, diameter, and processing method, number them sample 1, sample 2, and sample 3, and pour the three anchor rods with the same material and process. After pouring, the relationship between each part of the bolt and the rock is as follows: figure 1 Shown, where L is the total length of the bolt, L g is the length of the pouring part of the anchor rod, L f is the length of the unconsolidated part of the anchor rod, L=L g +L f ; Unconsolidated part of the anchor rod L f Consists of two parts, Lf =L b +L c , L b is the length of the unconsolidated part of the anchor rod in the hole (L b = 0 when the bolt is completely poured), L c is the part of the anchor rod protruding from the hole (L c = 0, the bolt is completely embedded in the rock). The anchor parameters of each sample after pouring are shown in Table 1.

[0088] Table 1 Geometric parameters of bolt sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com