A process for preparing Soong-Neung in aseptic package

A convenient and roasted rice technology, applied in food heat treatment, food science, etc., can solve the problems of Soong-Neung flavor loss, Soong-Neung quality deterioration, Soong-Neung can not be preserved for a long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

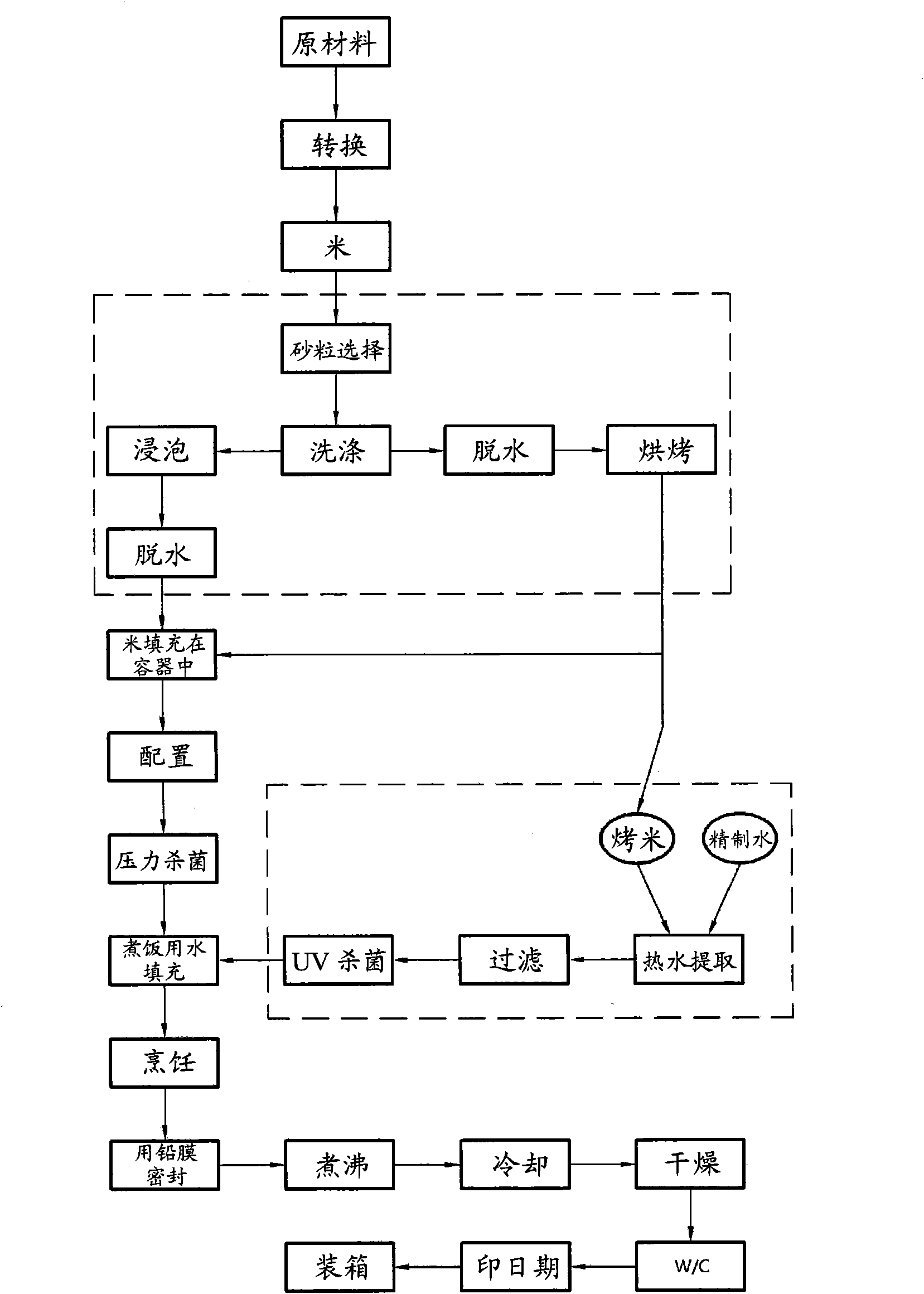

Method used

Image

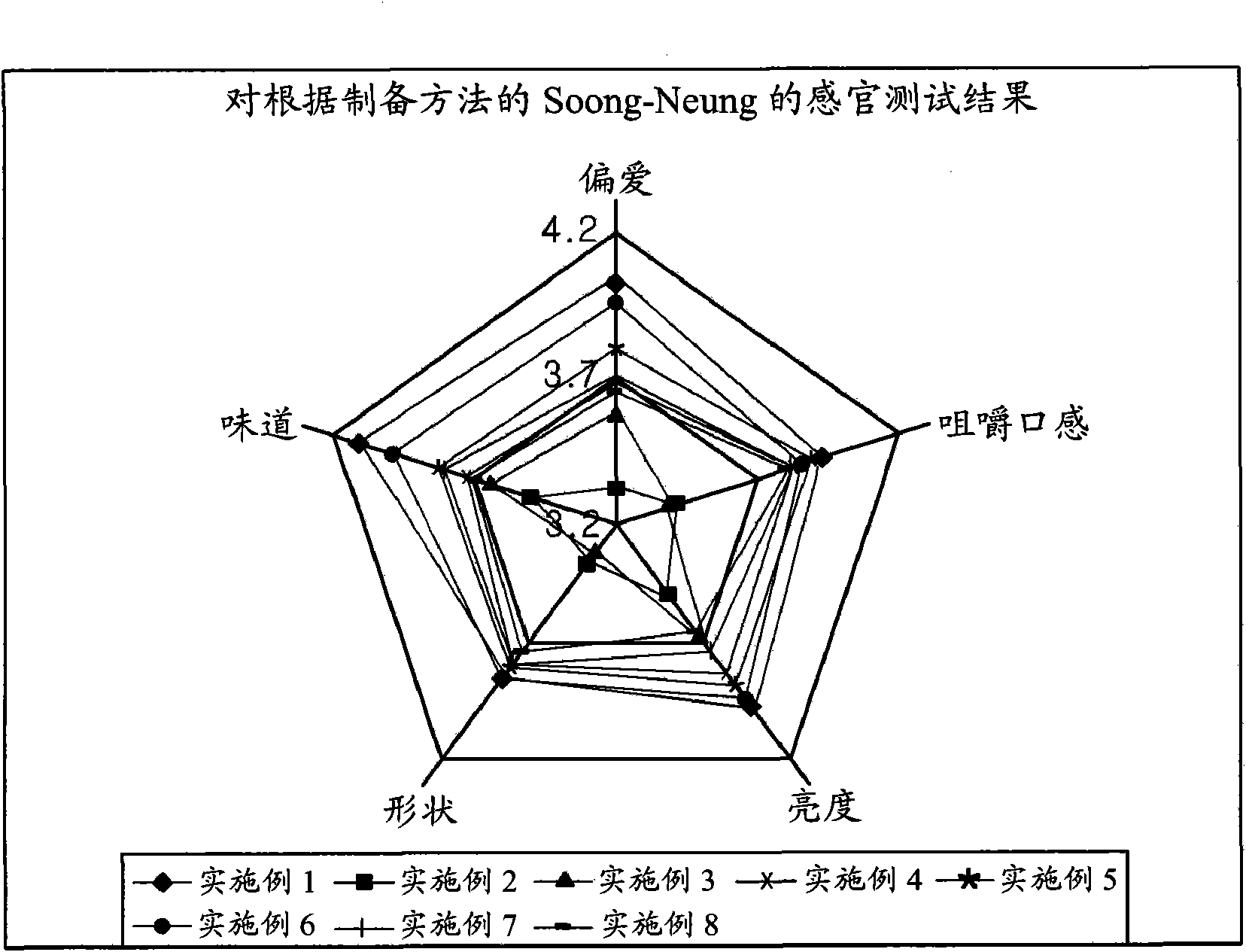

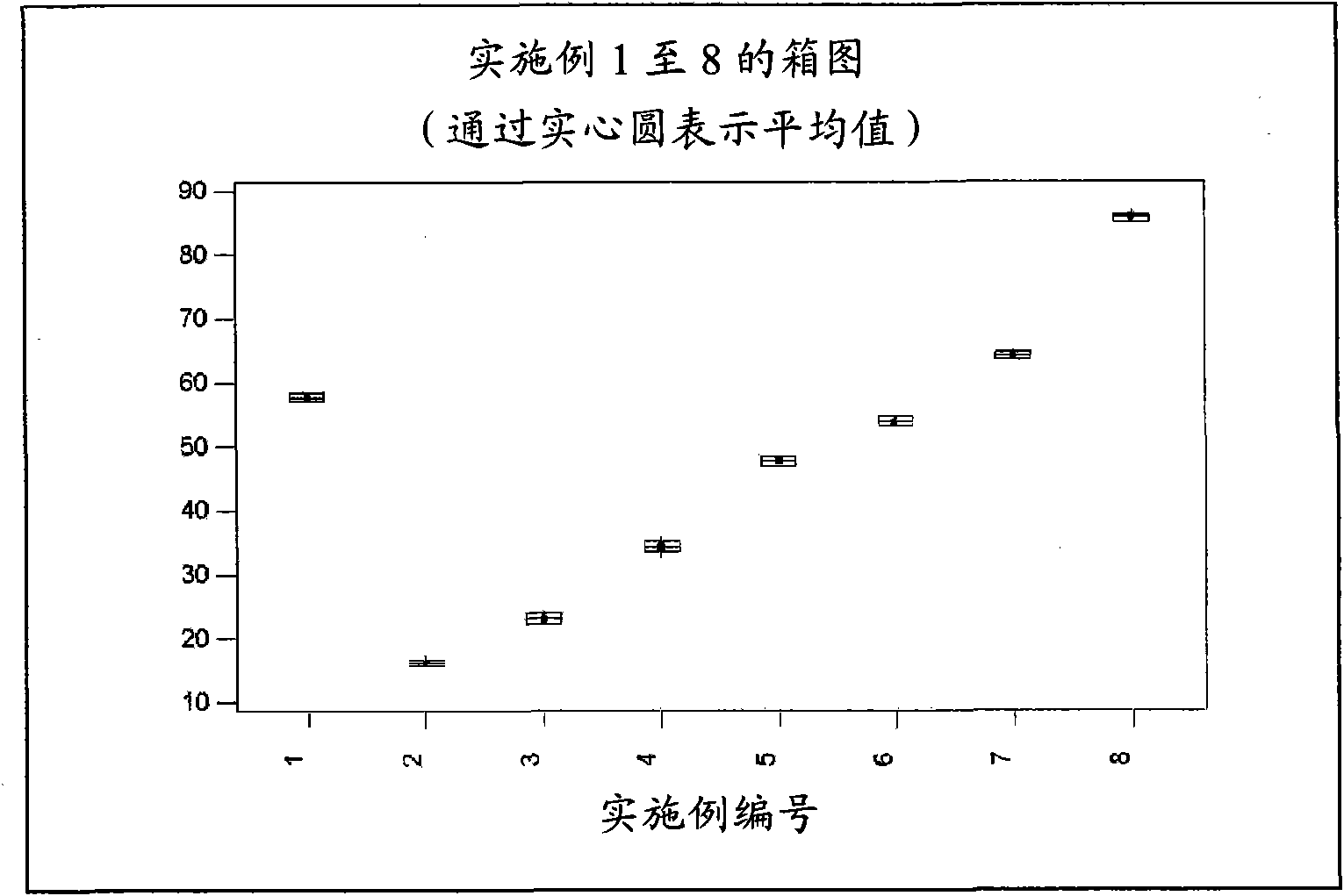

Examples

Embodiment 1

[0034] Wash 200 g of polished rice with water 5 times, soak it in water for 1 hour, and then remove water in a fine introduction net.

[0035] Nurunggi is prepared by adding 160 g of water to 200 g of polished rice and heating for 30 minutes. 230 g of water was added to 20 g of the obtained Nurunggi and 20 g of the cooked rice and heated for 10 minutes to prepare Soong-Neung.

Embodiment 2

[0037] Wash 200 g of polished rice with water 5 times, soak it in water for 1 hour, and then remove water in a fine introduction net.

[0038]20 g of polished rice and 20 g of commercially available (commercially available) Nurunggi were made into the container, and then the container was put into and sealed in a high-temperature and high-pressure sterilizer (Shinwa CO. High pressure steam for 5.0 seconds to sterilize. These high temperature steam sterilization processes were repeated 7 times.

[0039] After the high-temperature steam sterilization process, 230 g of rice cooking water (ordinary water) was added to each sterilized container. The container was uniformly kept in a rice cooker (rice cooker) at a steam temperature of 100° C. for 30 minutes to prepare Soong-Neung.

[0040] After completion of rice cooking (rice steaming), the container was sealed with a lead film and boiled for 12 minutes under aseptic conditions, and then Soong-Neung was prepared by cooling in wa...

Embodiment 3

[0042] Wash 200 g of polished rice with water 5 times, soak it in water for 1 hour, and then remove water in a fine introduction net.

[0043] The container was charged with 20 g of polished rice and 20 g of commercially available Nurunggi, and then the container was placed and sealed in a high-temperature and high-pressure sterilizer (Shinwa CO. Ltd,), followed by blowing high-pressure steam at 140 to 143° C. for 5.0 seconds to sterilize. These high temperature steam sterilization processes were repeated 7 times.

[0044] As a separate process, to 30 g of commercially available Nurunggi, 1000 g of water was added and hot water extracted at 90° C. for 30 minutes to prepare rice cooking water.

[0045] After the high temperature steam sterilization process, 230 g of rice cooking water was added to each sterilized container. The container was evenly kept in a rice cooker at a steam temperature of 100° C. for 30 minutes to prepare Soong-Neung.

[0046] After rice cooking was c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com