16-way Modular Adjacent Mutual Control Configuration Paper Break Detection Control Method for Newspaper Offset Press

A technology of detection control and offset printing machine, which is applied in the direction of printing and printing devices, can solve the problems of cost increase, excess resources, insufficient channels, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

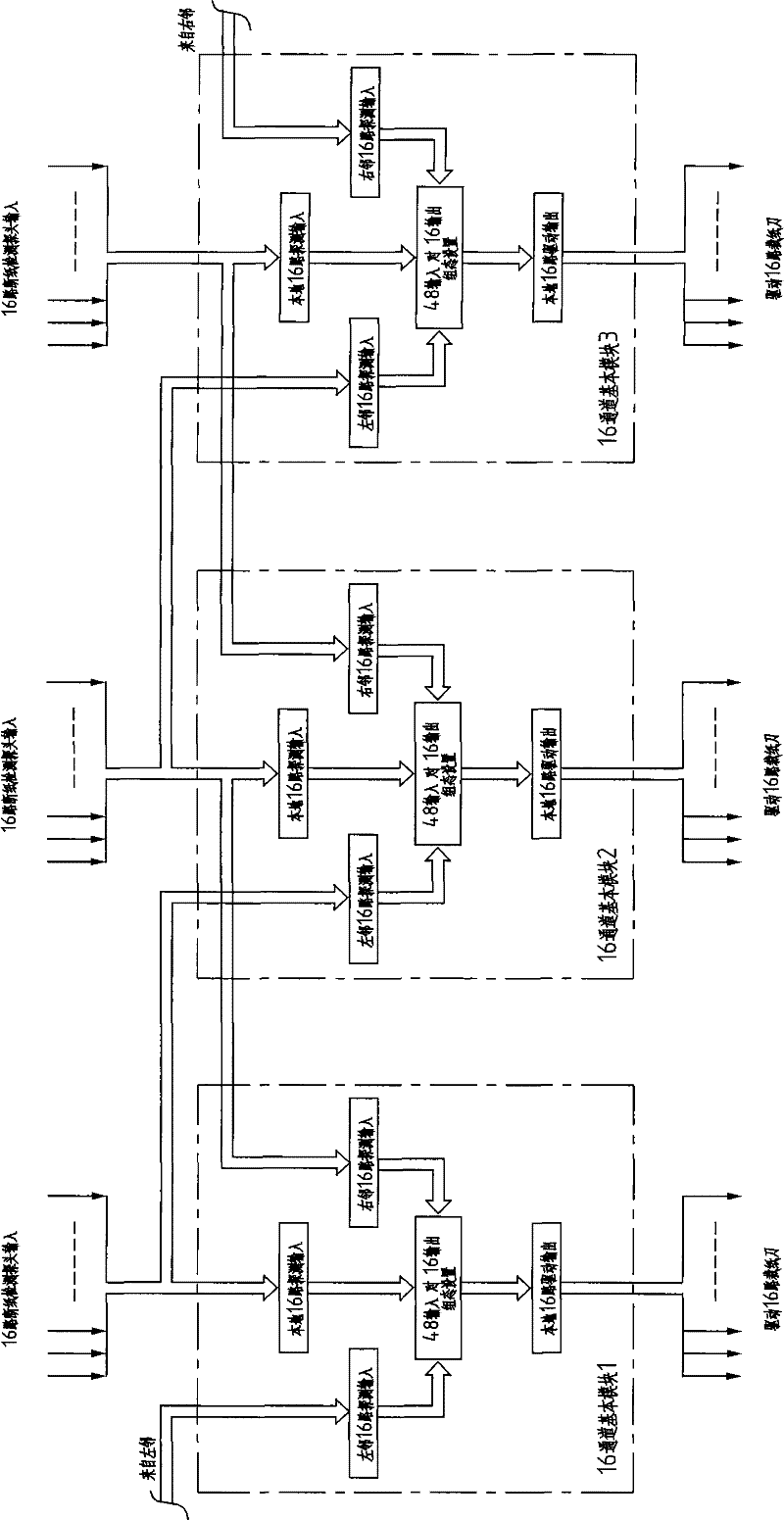

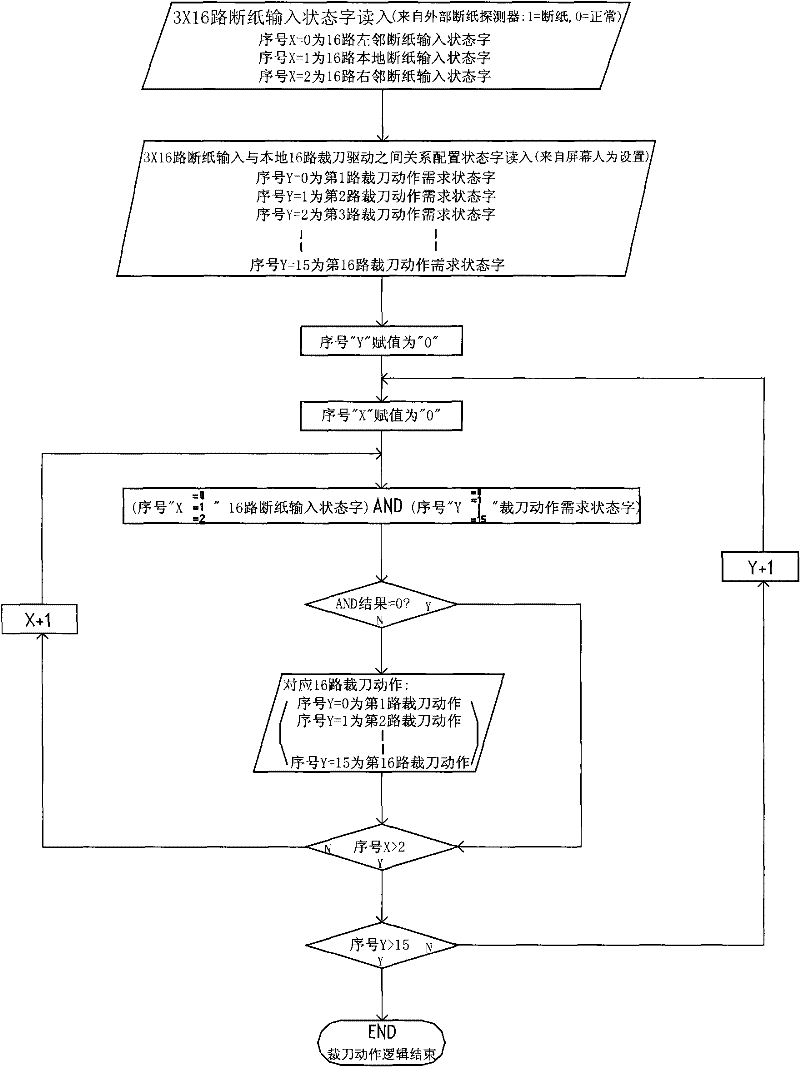

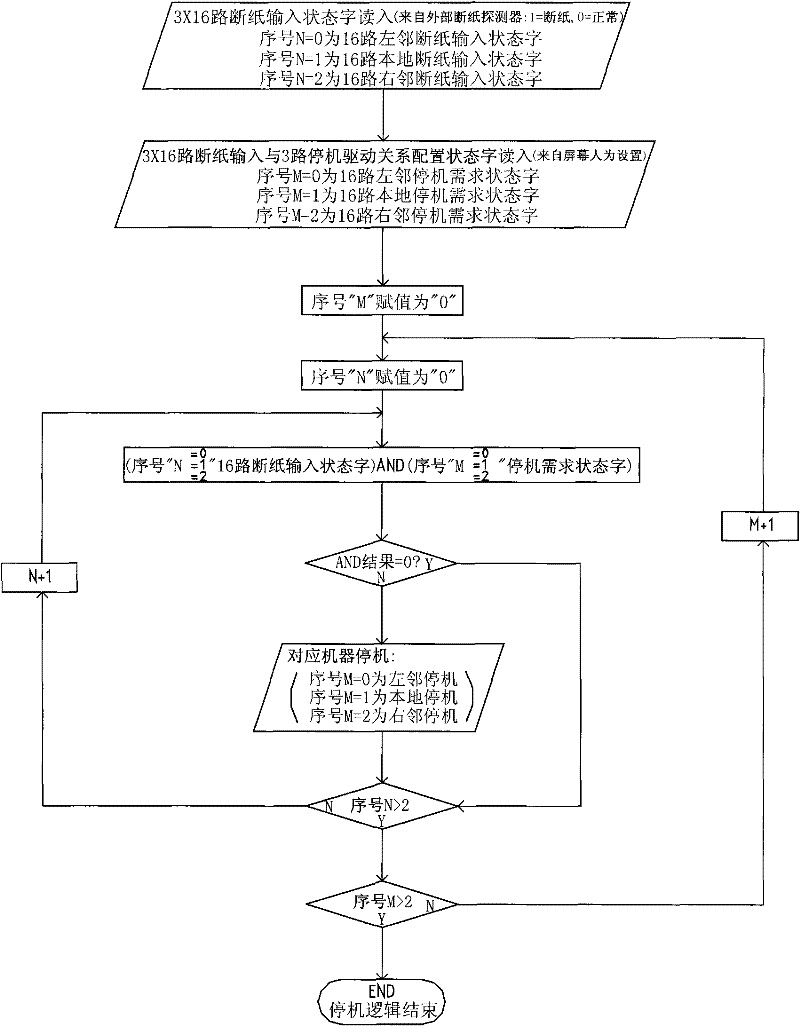

[0022] see figure 1 , a newspaper offset printing machine 16-way modular adjacent mutual control configuration paper break detection control method,

[0023] First, construct the basic module, which includes a microcomputer PC and a programmable logic controller PLC with 16 pairs of I / O input and output ports communicating with it, and the 16 pairs of I / O input and output ports are respectively connected to 16-channel Paper break detection head and 16-channel paper knife drive system, through the PC keyboard or screen, can freely configure 16 detection head inputs and 16 paper knife drive outputs; such a basic module itself has at least 4 The matching capability of the printing tower (16 printing units) for all production modes of the printing unit can cover the requirements of most small and medium-sized units for the paper path production mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com