Method and device for producing a multi-colored composite thread

A composite yarn and equipment technology, which can be used in feeding solution to spinnerets, melt spinning, transportation and packaging, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

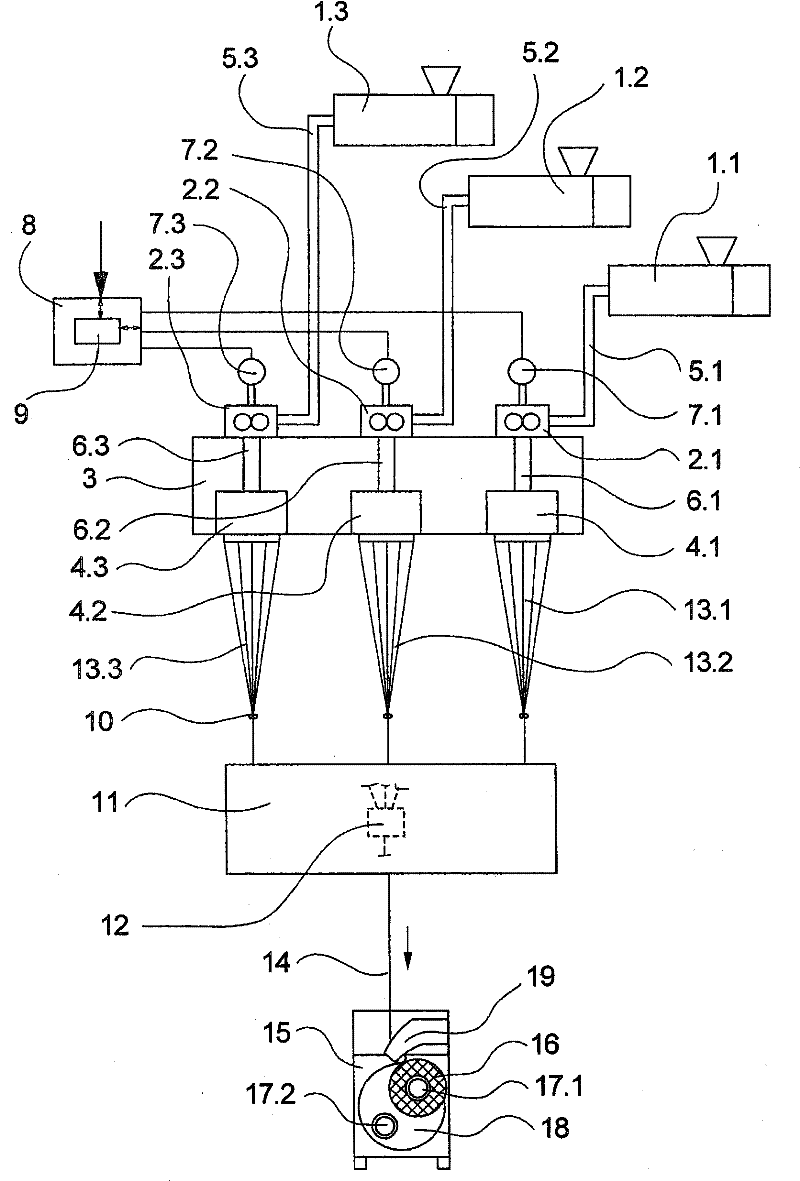

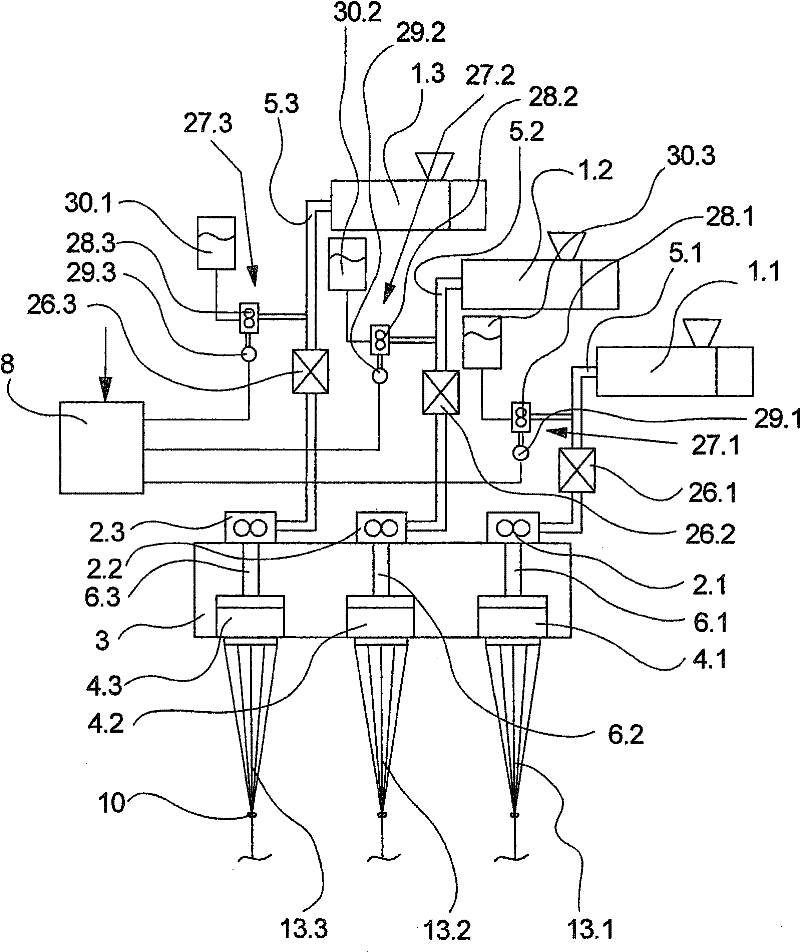

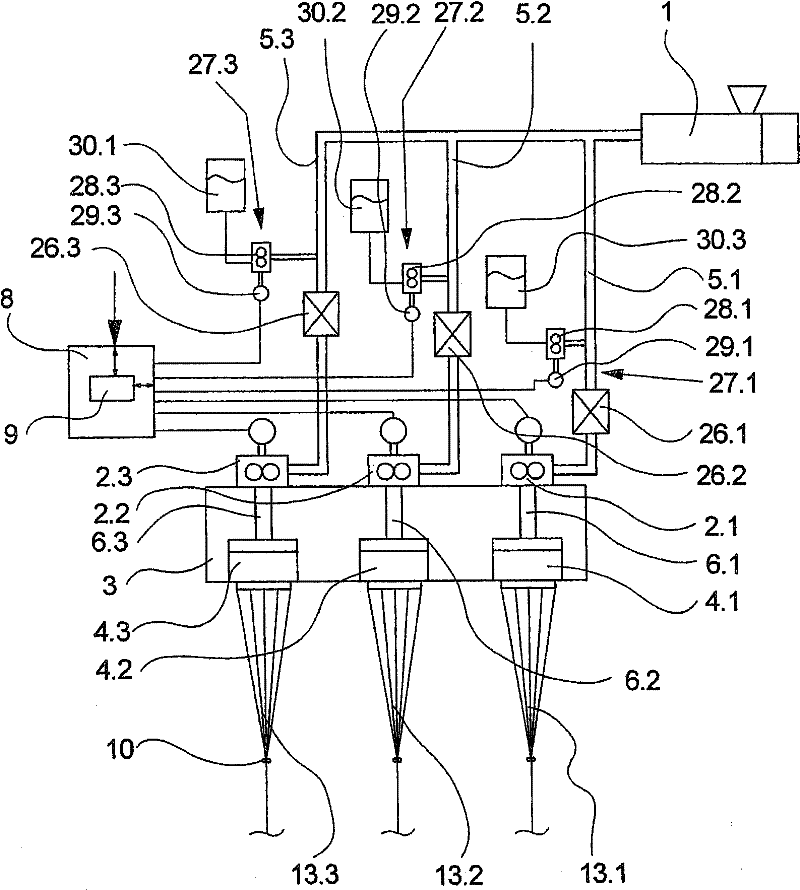

[0040] figure 1 A first embodiment of the device of the invention for performing the method of the invention is schematically shown. In order to extrude multiple colored monofilament bundles, the device has multiple spinnerets 4.1, 4.2 and 4.3. Spinnerets 4.1, 4.2 and 4.3 are arranged on the underside of the heated spinning box 3. In order to extrude a plurality of fine monofilaments respectively guided into monofilament bundles 13.1, 13.2 and 13.3, the spinnerets 4.1, 4.2 and 4.3 have spinnerets on their undersides, these spinnerets contain a plurality of spinneret holes . Such spinnerets are well-known, and therefore will not be described in more detail here.

[0041] In order to extrude the monofilaments, colored polymer melts are fed to the spinnerets 4.1, 4.2 and 4.3 respectively. To this end, each spinneret 4.1, 4.2, and 4.3 is equipped with a spinning pump 2.1, 2.2, and 2.3, respectively. The spinning pumps 2.1, 2.2, and 2.3 transfer the corresponding polymer melt throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com