Overweight loading detection method for rail wagon

A technology of bearing weight and detection method, which is applied in the direction of weighing, measuring devices, instruments, etc., can solve the problems of affecting the efficiency of railway freight transportation, easy subjective judgment, complicated operation, etc., and achieve the effect of convenient overloading and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

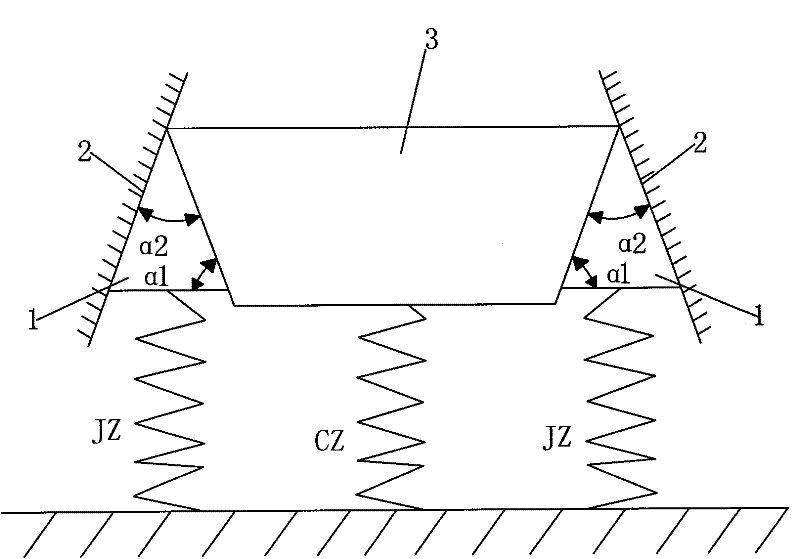

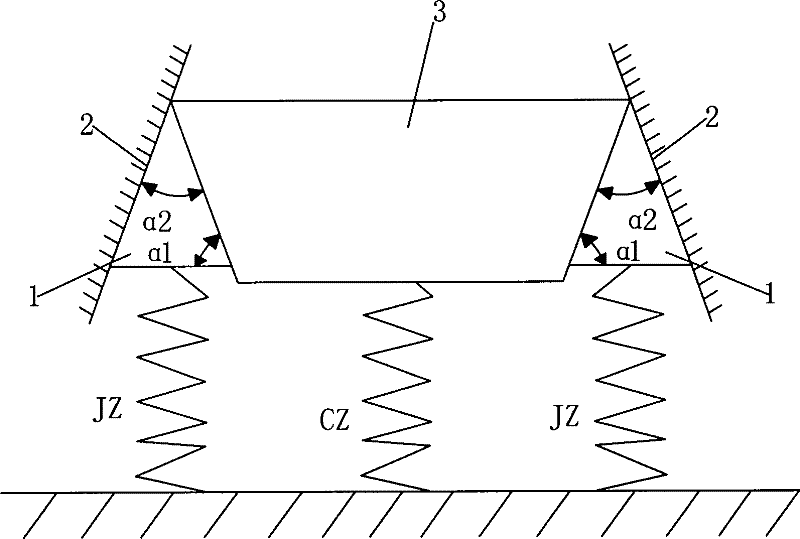

Method used

Image

Examples

Embodiment Construction

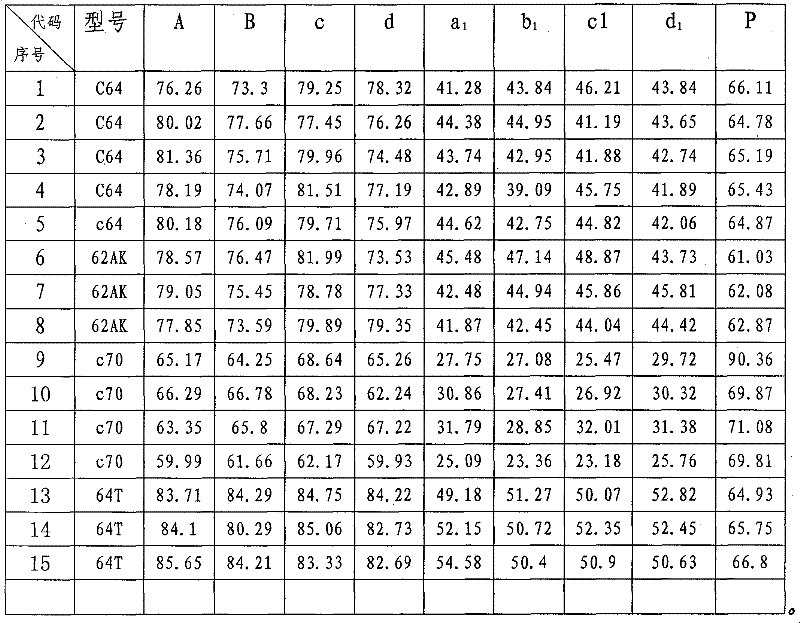

[0048] The height values of the spring set a, b, c, d when the car is empty and the height value a of the spring set when the car is heavy are measured in the following table 1 , b 1 , c 1 , d 1 , for example:

[0049] a

b

c

d

a 1

b 1

c 1

d 1

p

p 1

76.26

73.3

79.25

78.32

41.28

43.84

46.21

43.24

66.1

66.11

[0050] G 1 =(a+b+c+d) / 4, G 1 =(76.26+73.3+79.25+78.32) / 4=76.78

[0051] G 2 =(a 1 +b 1 +c 1 +d 1 ) / 4, G 2 =(41.28+43.84+46.21+43.84) / 4=43.79

[0052] F=76.78-43.79=32.99

[0053] S=F-D S=32.99-33=-0.01

[0054] U=SIGN(S)=-1

[0055] k=ROUND(493.5-(-1×(0.01+0.765)×10), 2)=501

[0056]P=ROUND(501×32.99)×4 / 1000=66.11t

[0057] Track scale weight: 66.1 difference 0.01kg

[0058] Several sets of actual test data are as follows: (P is the weight of the track scale)

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com