Driving mechanism

A technology of a transmission mechanism and a rotating disk, which is applied to transmission parts, mechanical equipment, instruments, etc., can solve the problems of inability to perform more precise self-locking position control, less self-locking times, and complex mechanism design, and achieve fine scrolling positioning. Effect, the effect of multiple self-locking times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention. Furthermore, the same elements are denoted by the same reference numerals in each drawing.

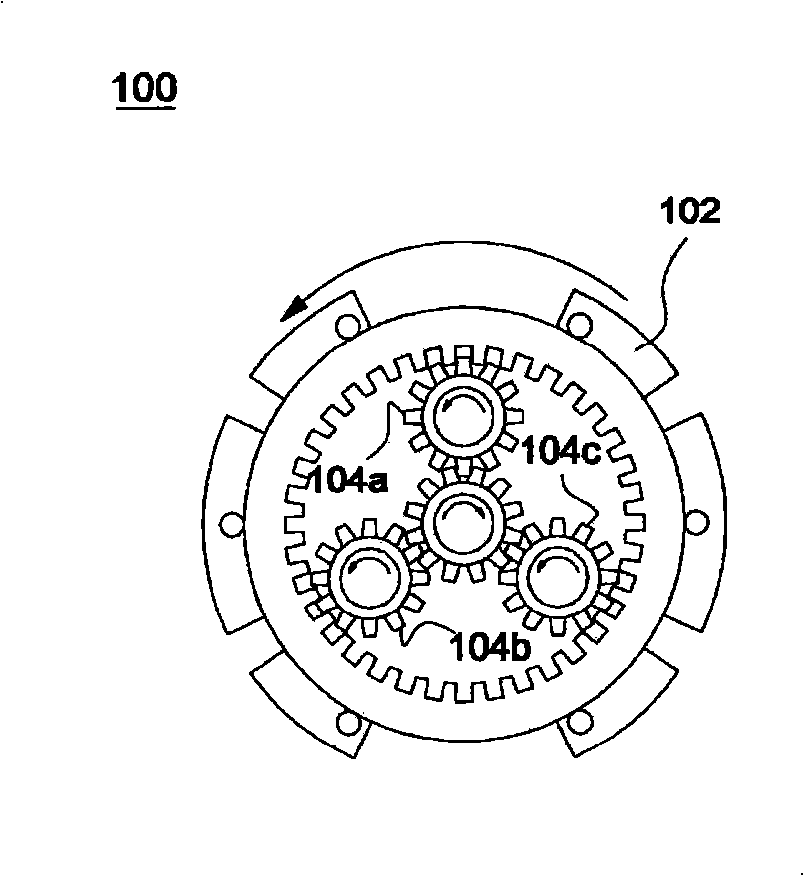

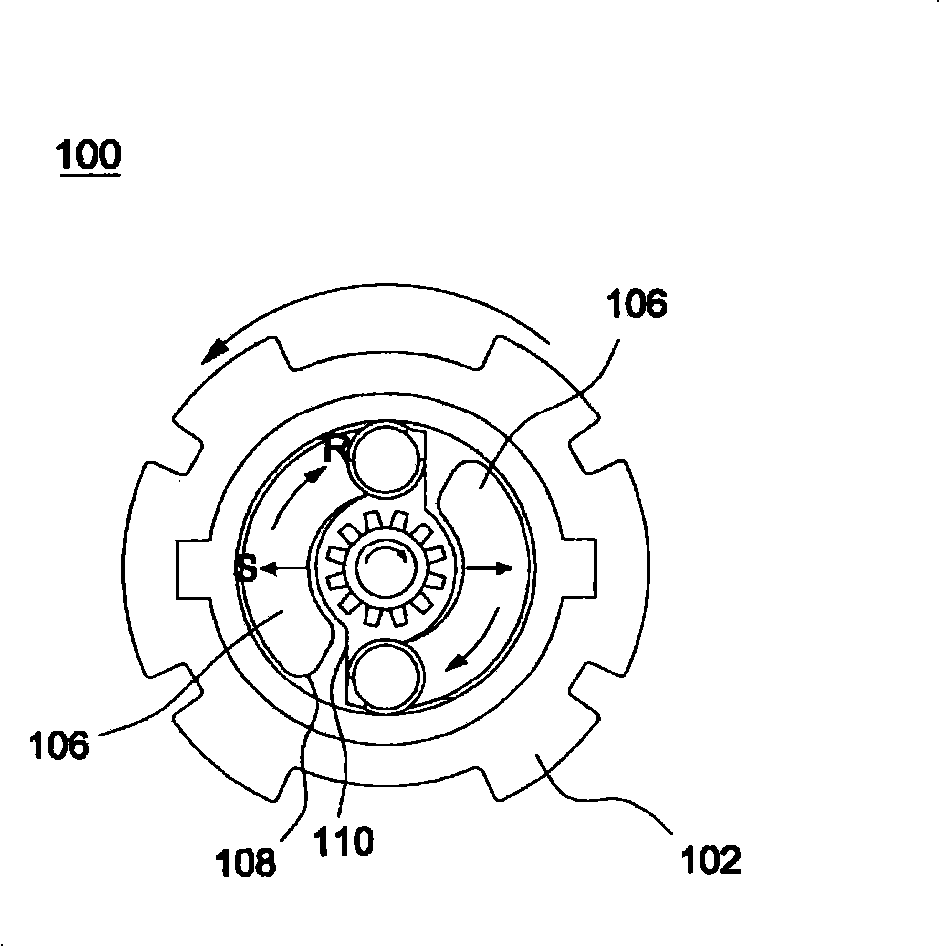

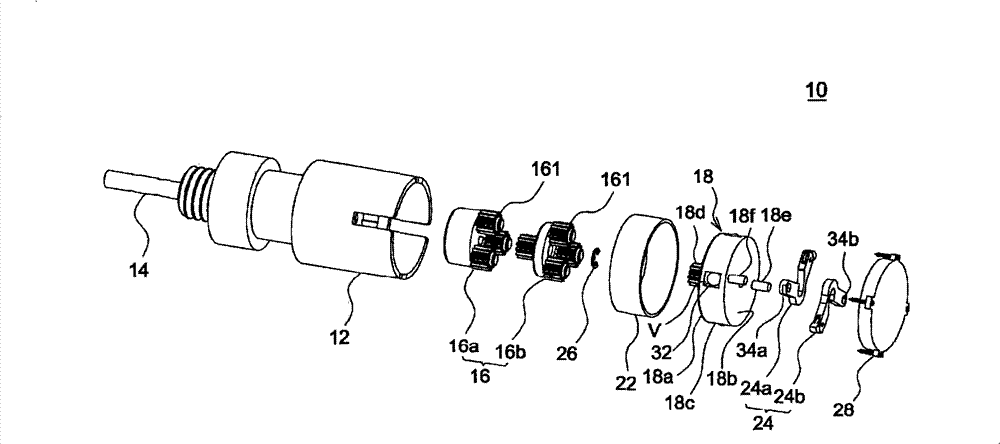

[0064] figure 2 According to an embodiment of the present invention, an exploded view showing a transmission mechanism 10 with deceleration and self-locking functions, image 3 It is an enlarged schematic diagram of the transmission mechanism 10 after assembly. The transmission mechanism 10 can be applied to a projection curtain, for example. When a projection curtain is manually pulled down or retract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com