Wheel wear resistance combined test stand of rail vehicle

A comprehensive test bench and rail vehicle technology, applied in the field of rail vehicle wheel wear resistance comprehensive test bench, can solve the problems of restricting rapid development, long research cycle of wheel wear resistance, low efficiency, etc., and achieve the effect of shortening the research cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

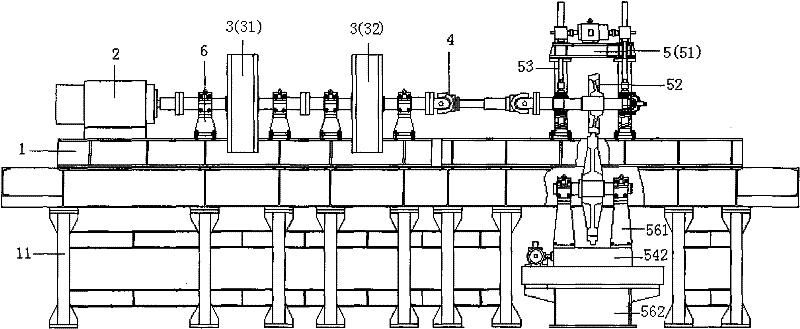

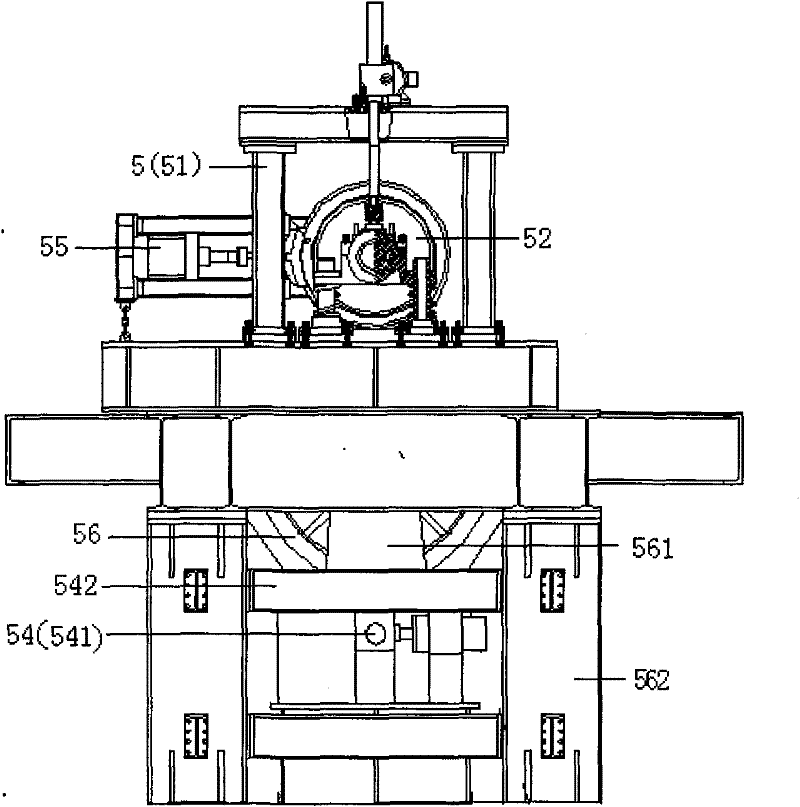

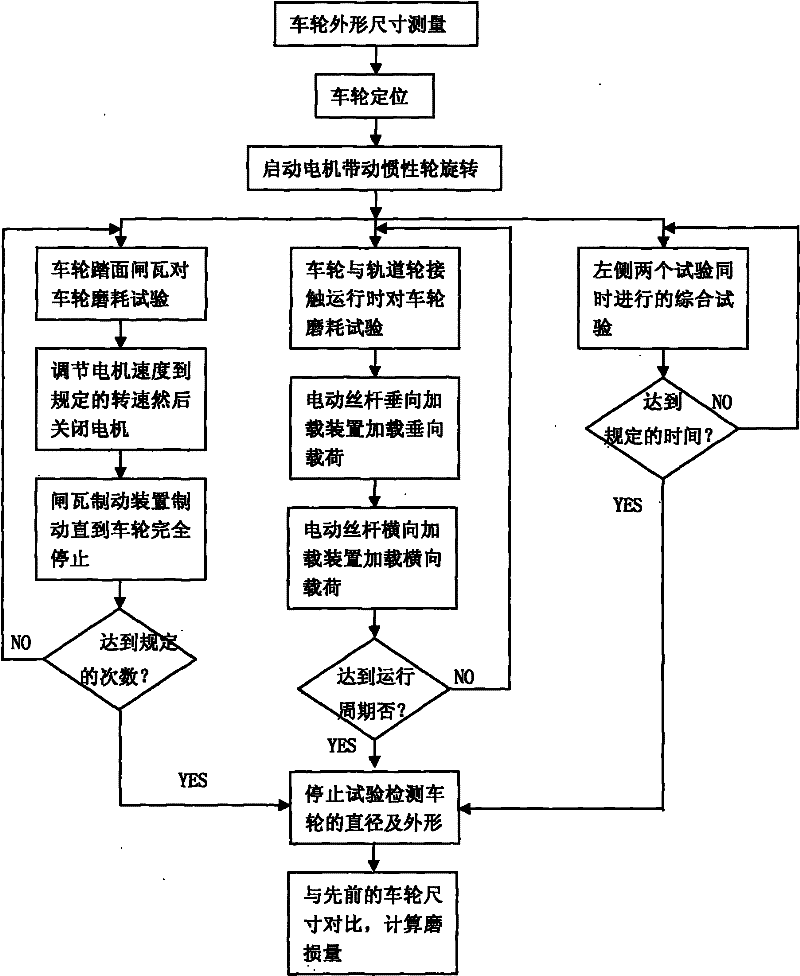

[0019] like figure 1 , 2 As shown, the mechanical assembly of the present invention is mainly composed of an underframe 1, a motor and its speed regulating device 2, an inertial wheel set 3, a universal coupling 4, and a wheel test device 5. The wheel test device is mainly composed of a frame body 51, a test wheel 52 installed on the frame body, an electric vertical loading actuator 53 for the test wheel, a lateral loading actuator 54, a brake shoe brake 55, and a track wheel 56. Described inertial wheel set 3 is provided with first inertial wheel set 31 and second inertial wheel set 32 of equal size. Between the first inertial wheel set and the second inertial wheel set, between the first inertial wheel set and the output shaft of the motor, between the second inertial wheel set and the universal shaft coupling, bearings and bearing seat supporting columns 6 are arranged, and the bottom of the supporting column is located at On the bottom frame 1, the bottom frame 1 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com