Magnetic head folded-piece combined general tray and general tray combination thereof

A tray and magnetic head technology, applied in magnetic recording, instruments, record carrier structural parts, etc., can solve problems such as high cost and reduce production efficiency, and achieve the goal of reducing workstations and operators, improving production efficiency and reducing manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

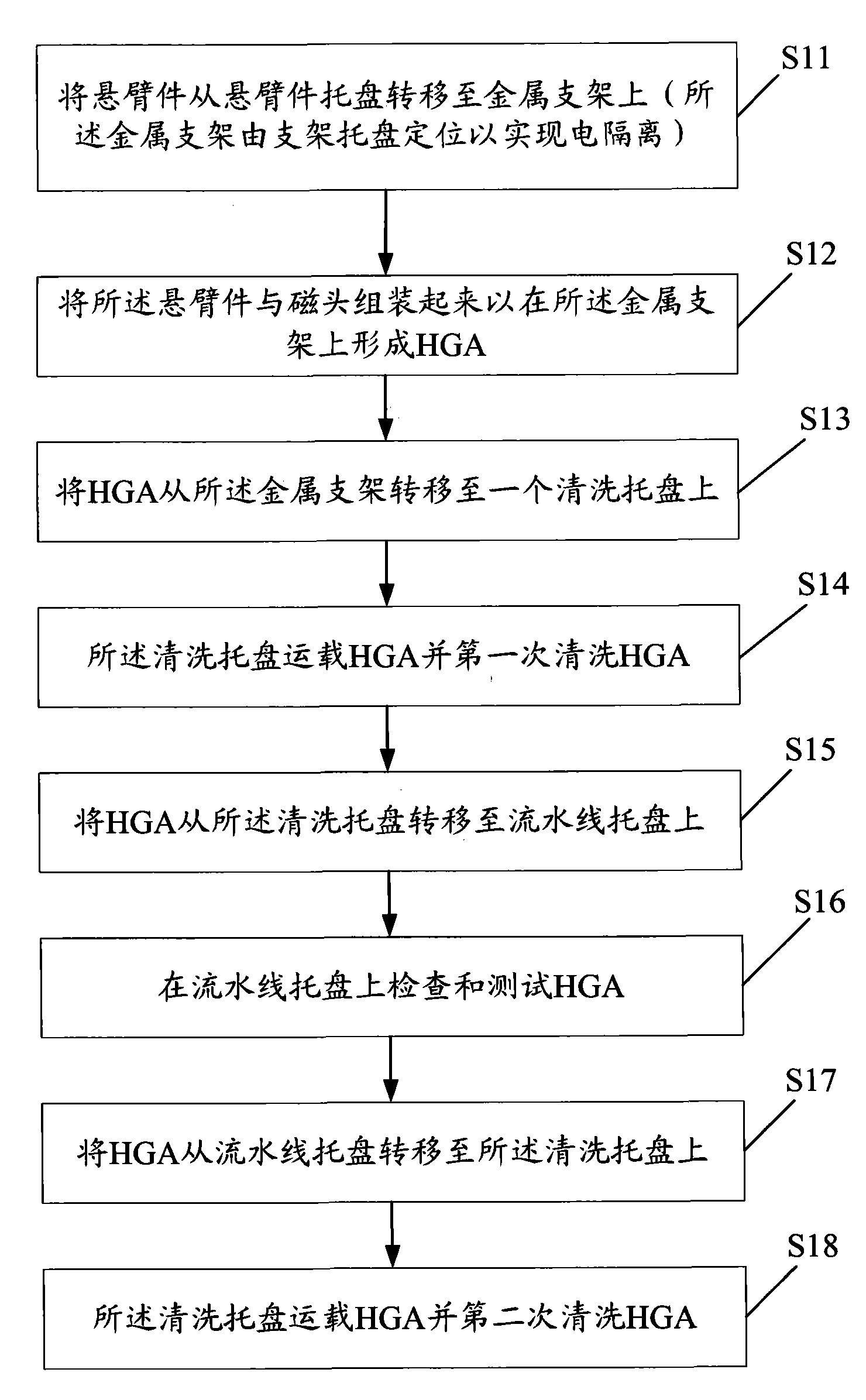

[0026] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As described above, the present invention provides a HGA universal tray and its universal tray assembly, which can replace the five trays used in the traditional HGA manufacturing process to carry, clean and test the HGA of the hard disk drive. Therefore, pallet cost is reduced, manufacturing process is simplified and production efficiency is improved. A detailed description will be given below.

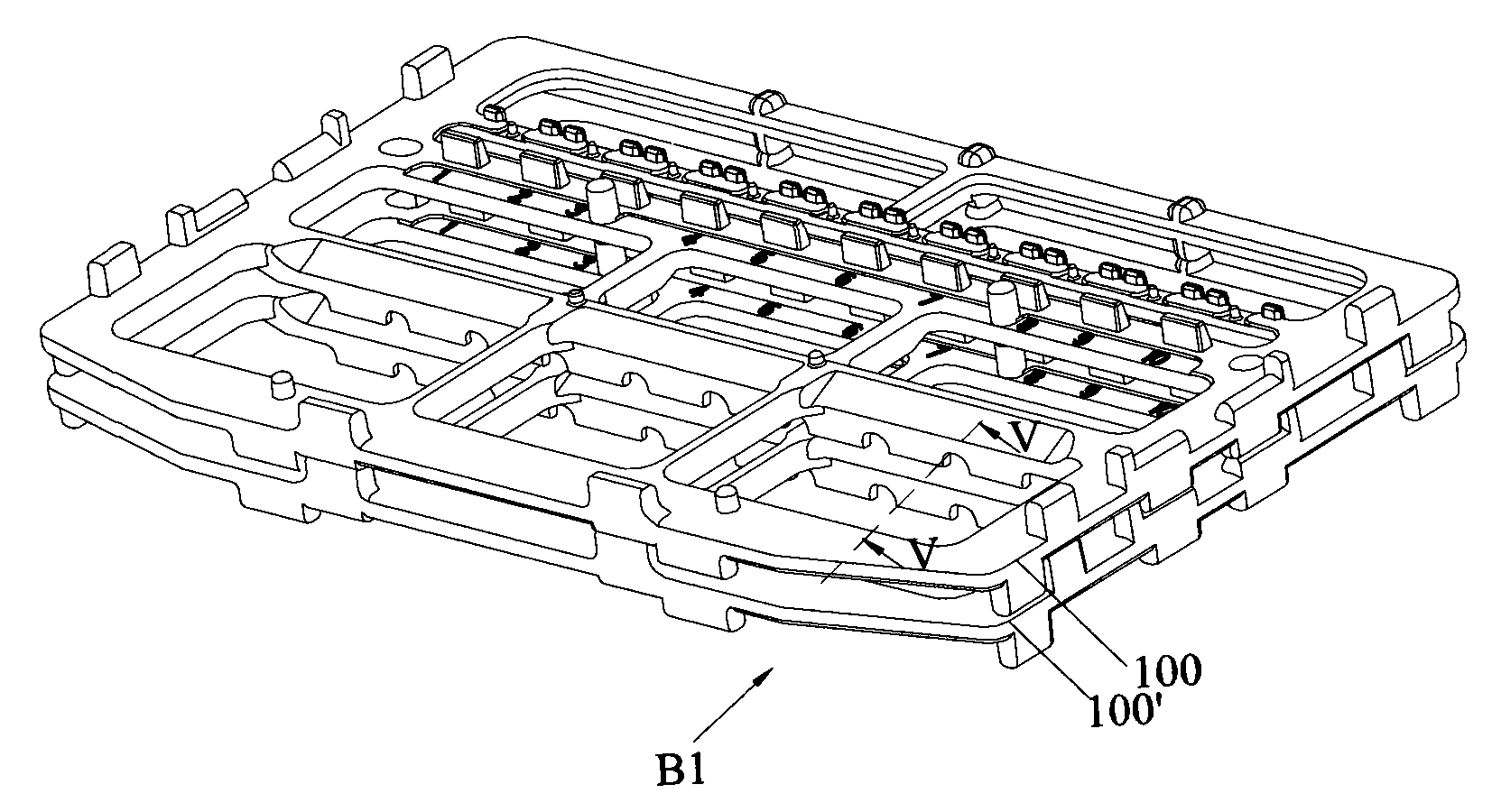

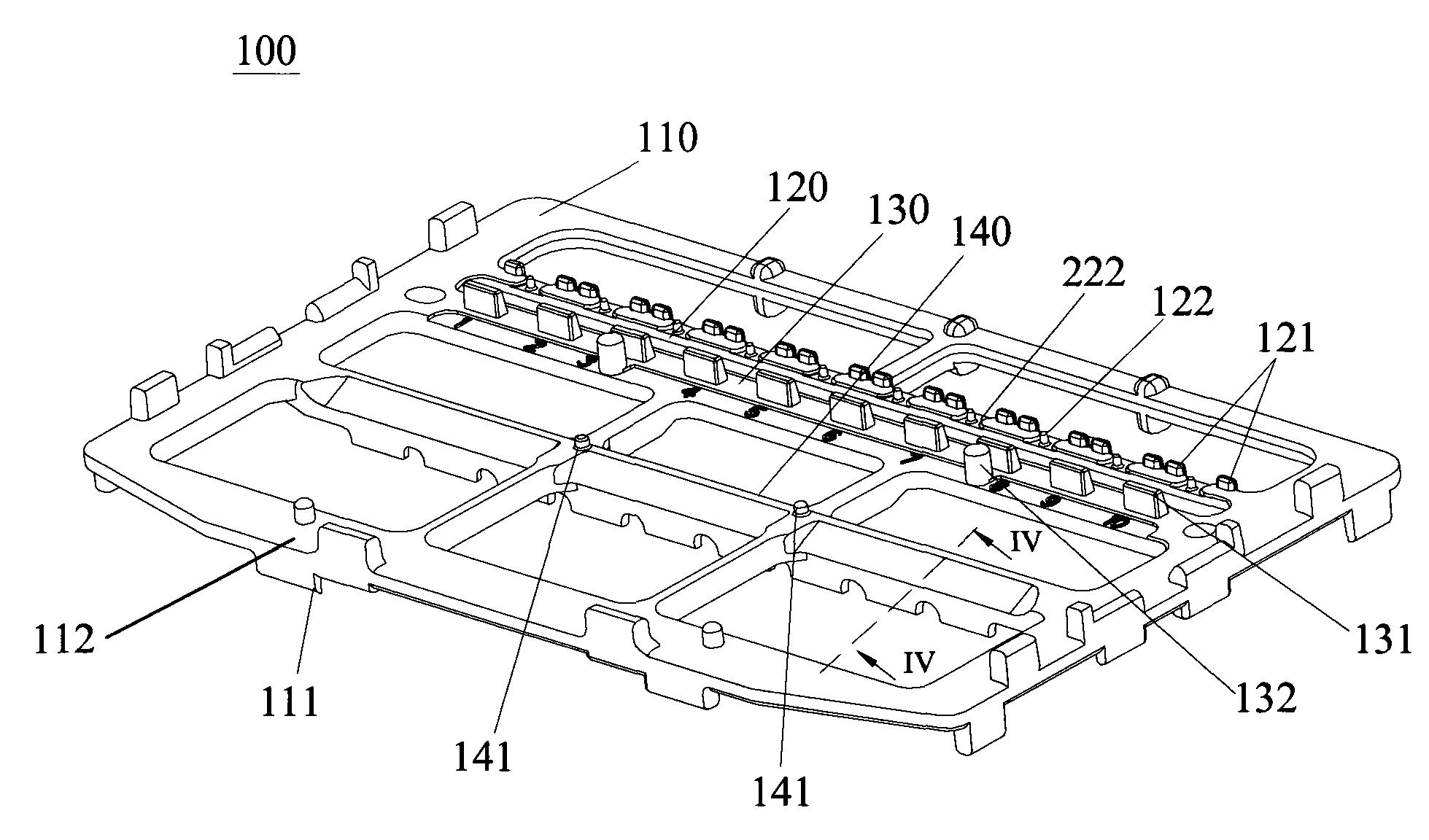

[0027] Such as figure 2 As shown, the universal tray assembly of the HGA of the present invention includes several universal trays with the same structure. In this embodiment, the universal pallet assembly includes two stacked universal pallets 100, 100'. The structure of the universal tray 100 will be described below. refer to image 3 , the universal tray 100 includes an outer frame 110 having at least two opposite sides, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com