Shunt device

The technology of a shunt device and a shunt cone, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of decreased mechanical properties and uneven organization of pipe products, and achieves the effect of less obvious traces and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

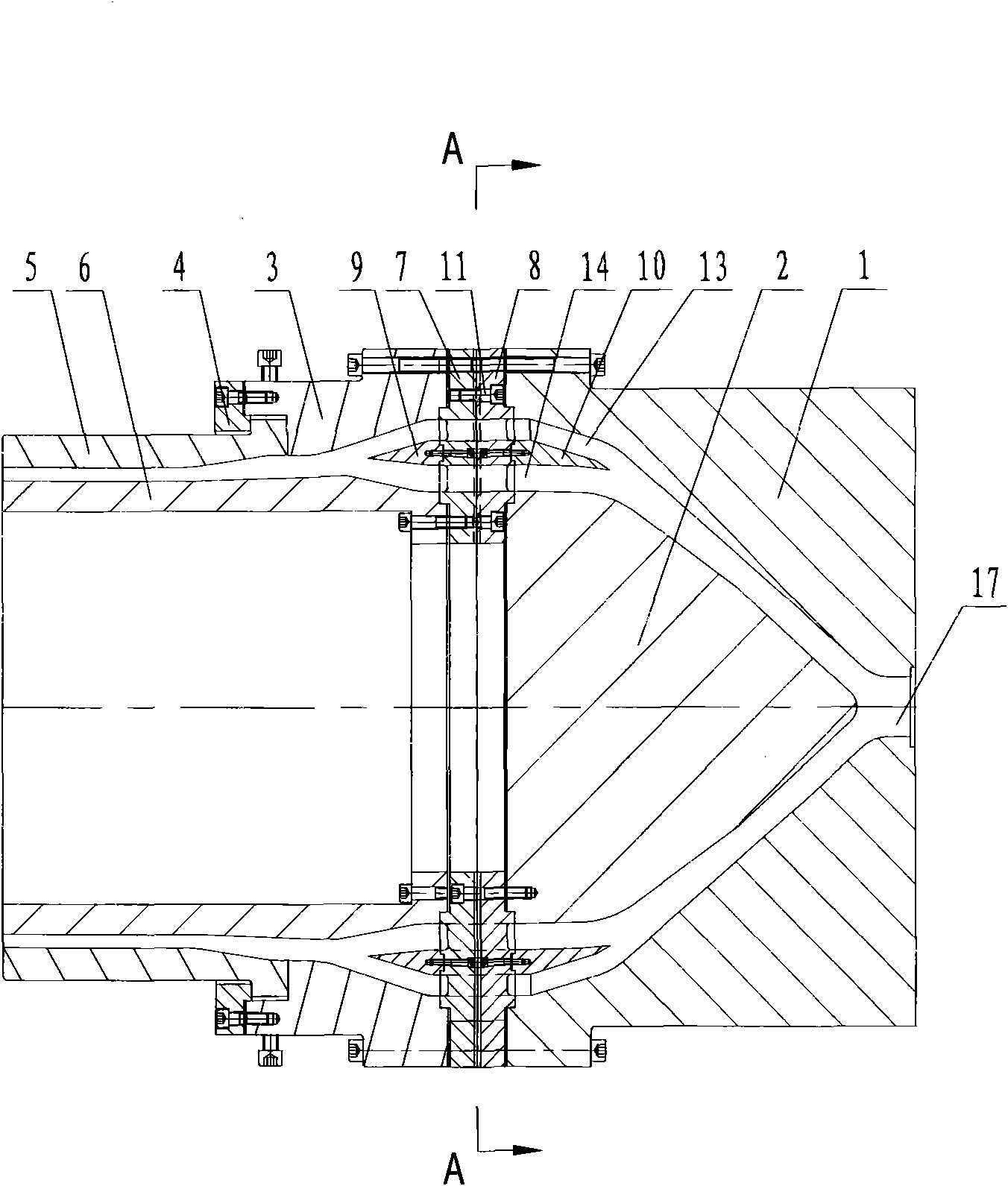

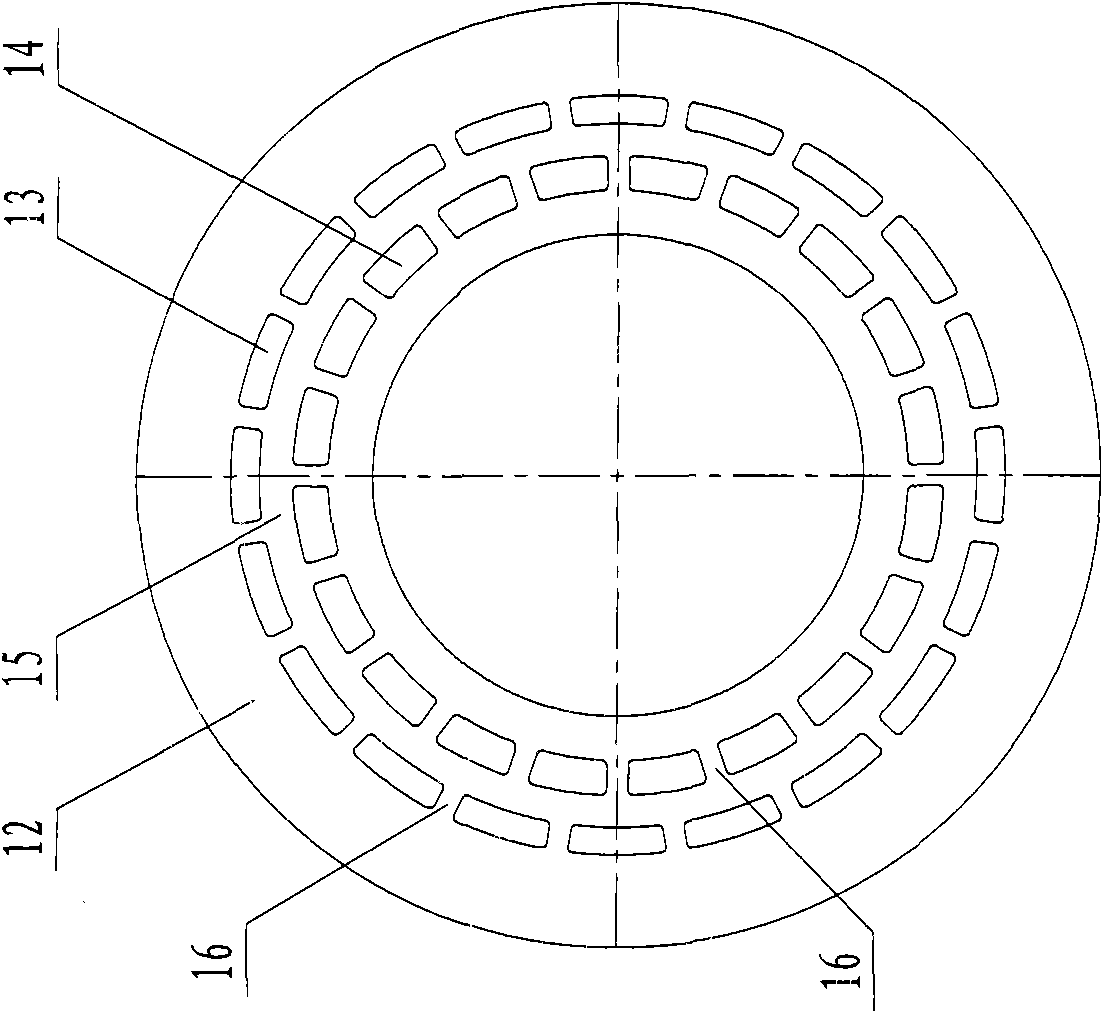

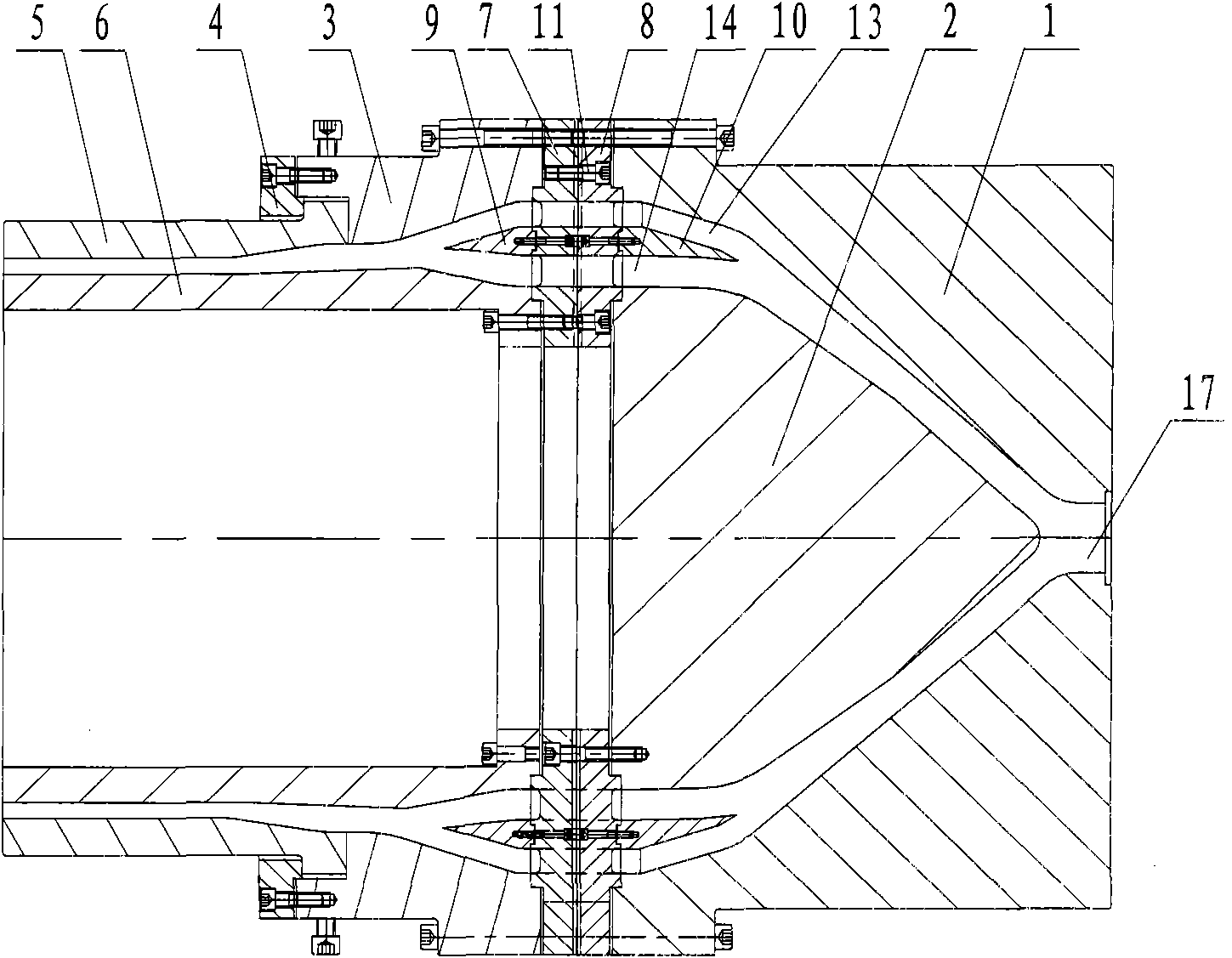

[0013] Embodiment one: see attached figure 1 And attached figure 2 shown.

[0014] A diverter device, comprising a tail die set 1 provided with a feed port 17, a diverter cone 2, an adjustment ring 3, a pressure plate 4, a die 5, a mandrel 6 arranged inside the die 5, the die set 1 and the diverter Between the cones 2, between the adjustment ring 3 and the mandrel 6, between the die 5 and the mandrel 6, there are flow passages connected. , the rear small shunt cone 10, the front half shunt bracket 7 and the rear half shunt bracket 8 are connected by screws 11 to form a shunt bracket 12, the shunt bracket 12 is fixed between the tail mold cover 1 and the adjustment ring 3, and the corresponding flow on the shunt bracket 12 The position of the channel is provided with a flow channel hole, the diverter cone 2 is fixed on the side of the diverter bracket 12 close to the tail mold cover 1, and the mandrel 6 is fixed on the side of the diverter bracket 12 close to the adjustment ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap