Double-sided metal wired capacitive screen functional plate

A metal wiring, double-sided metal technology, which is applied in electrical digital data processing, data processing input/output process, instruments, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

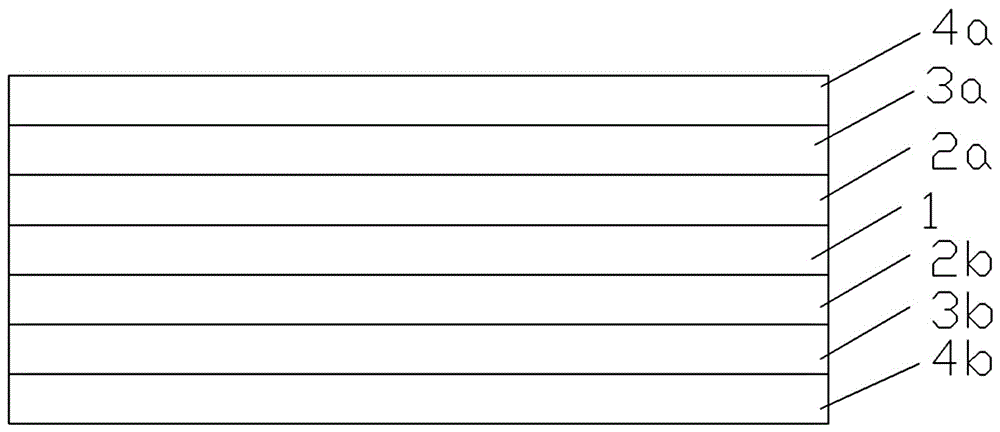

[0011] Such as figure 1 As shown, the present invention provides a capacitive screen functional sheet with double-sided metal wiring, including a glass substrate 1, and the top surface of the glass substrate 1 is sequentially provided with an upper shadow elimination layer 2a, an upper metal wiring layer 3a and a top elimination layer. The shadow layer 4a, the bottom surface of the glass substrate 1 is sequentially provided with the lower shadow erasing layer 2b, the lower metal wiring layer 3b and the bottom shadow erasing layer 4b, and the upper metal wiring layer 3a and the lower metal wiring layer 3b are both integral Surface metal wiring, the impedance of the upper shadow erasing layer 2a matches the upper metal wiring layer 3a, and the lower shadow erasing layer 2b matches the impedance of the lower metal wiring layer 3b.

[0012] During specific manufacturing, the glass substrate 1 can adopt conventional functional glass, and the operating parameters of the upper shadow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap