Photoelectric device with variable resistor structure

A resistance structure and photoelectric device technology, which is applied in the direction of circuits, electrical components, and electrical solid-state devices, can solve the problems of unable to improve production efficiency, labor and time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail and drawn in the drawings, and the same or similar parts will appear in the drawings and descriptions with the same symbols.

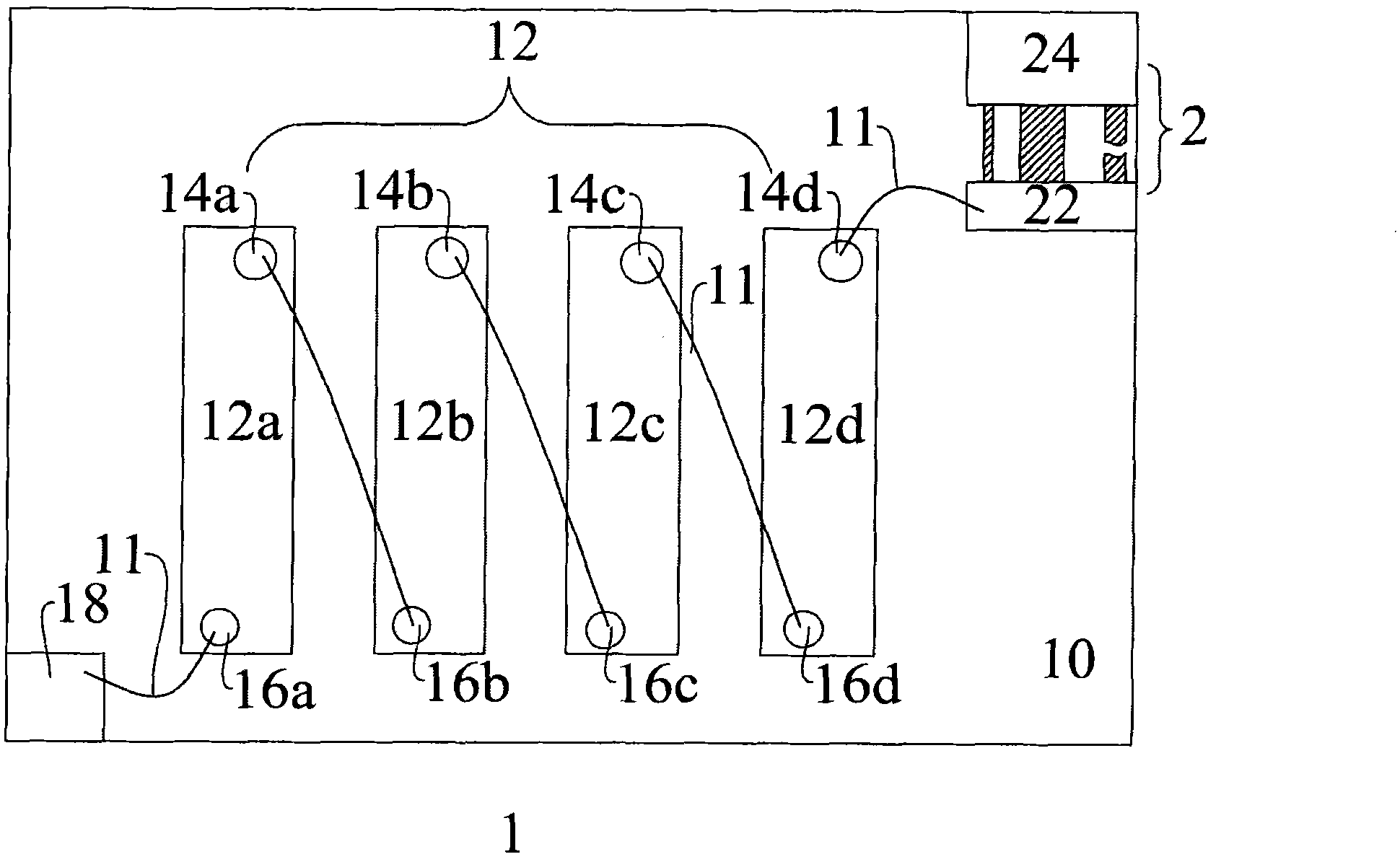

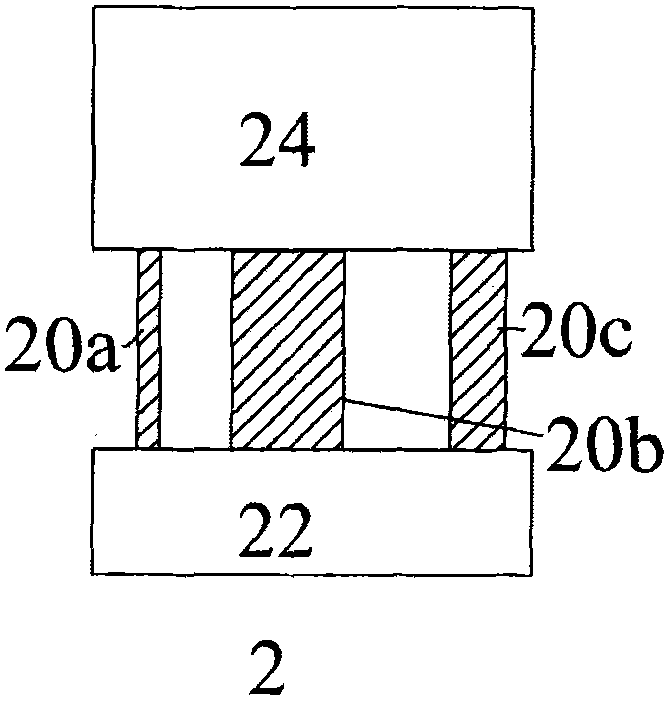

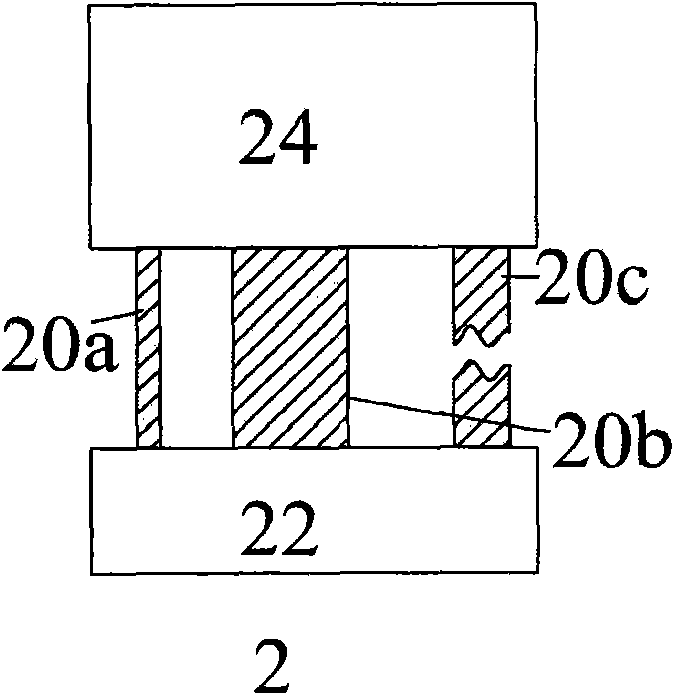

[0035] Such as figure 1 As shown, the first embodiment of the photoelectric device 1 having a variable resistance structure includes a substrate 10; a photoelectric element array 12 is formed on the substrate 10, wherein the photoelectric element array 12 includes a first photoelectric element 12a, a second photoelectric element 12b, The third photoelectric element 12c and the fourth photoelectric element 12d. Here, the photoelectric elements of the photoelectric element array 12 are connected in series as an example. The first electrode 14a of the first photoelectric element 12a and the first electrode of the second photoelectric element 12b 14b and the first electrode 14c of the third photoelectric element 12c are respectively connected to the second electrode 16b of the second ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap