Excavator for building tunnel type passage

An excavator and pipeline-type technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve problems such as unsatisfactory excavation requirements, achieve the effects of shortening emergency rescue time, reducing production costs, and simplifying structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

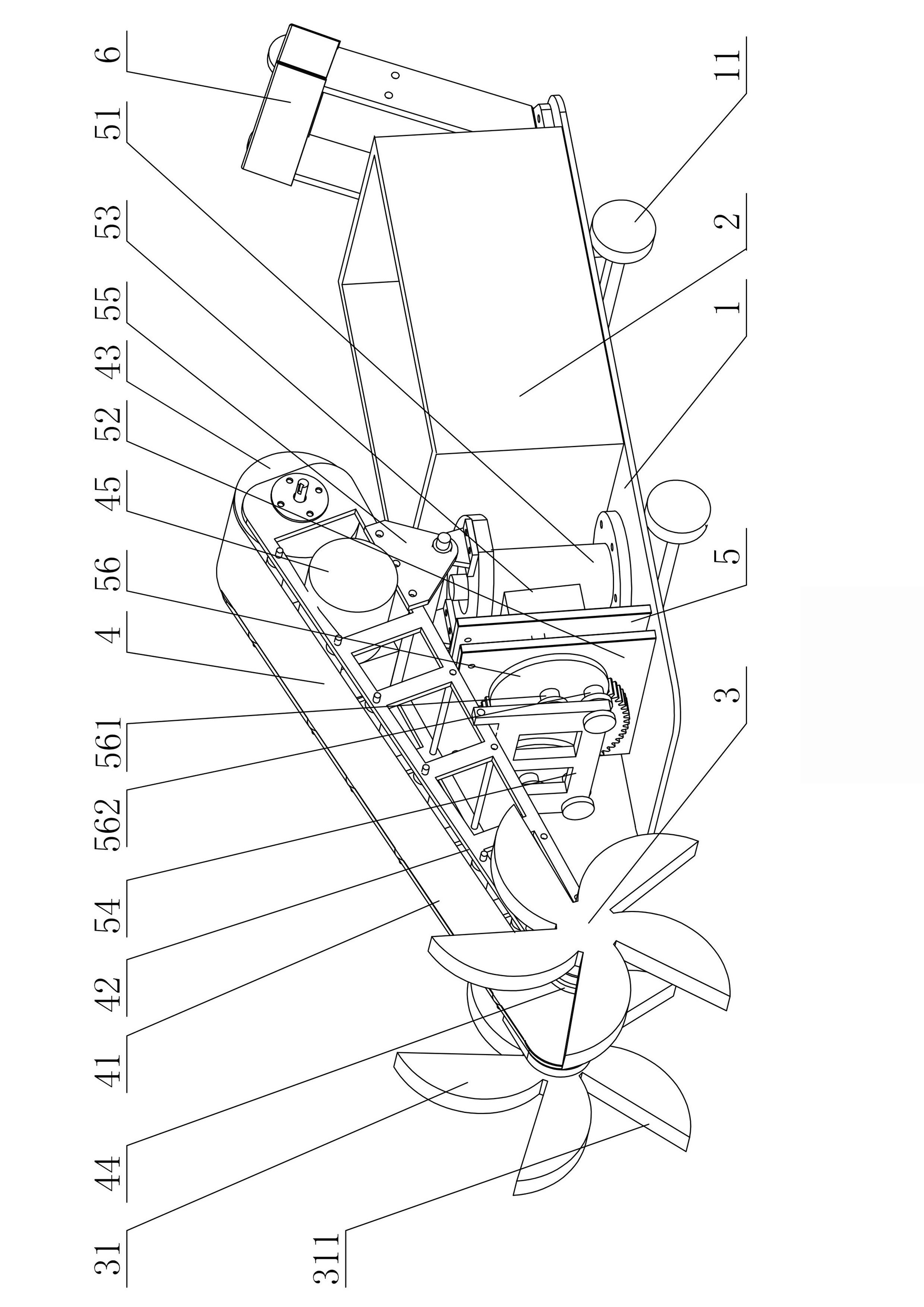

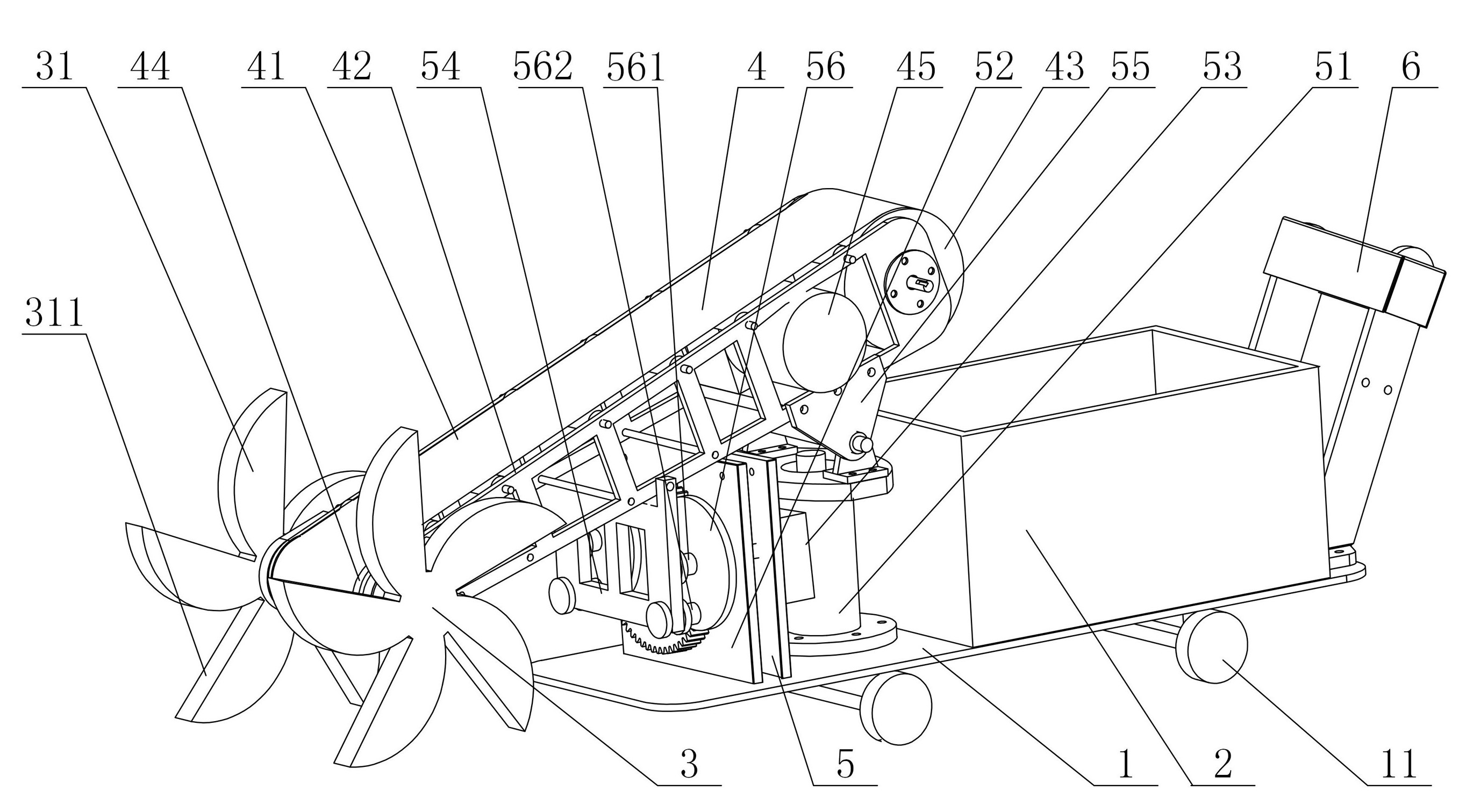

[0016] figure 1 It shows an excavator for constructing a pipeline channel according to the present invention, including a rail-type carrying platform 1, a soil loading box 2, a wheeled excavating mechanism 3, a belt transmission mechanism 4 and a deflection mechanism 5, and the soil loading box 2 is loaded Located at the rear end of the track-type carrying platform 1, the deflection mechanism 5 is installed at the front end of the track-type carrying platform 1, the belt transmission mechanism 4 is installed above the deflection mechanism 5 and is driven to deflect by the deflection mechanism 5, and the tail end of the belt transmission mechanism 4 is placed Above the soil loading box 2, a wheeled excavating mechanism 3 is installed on the front end of the belt transmission mechanism 4. The wheeled excavating mechanism 3 includes a pair of excavating wheels 31, and a pair of excavating wheels 31 is provided with a belt that can guide the excavated soil to the belt. The spiral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com