Fiber reinforced core panel

A fiber reinforced, core board technology that can be used in building components, vehicle components, applications, etc., to solve problems such as low surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

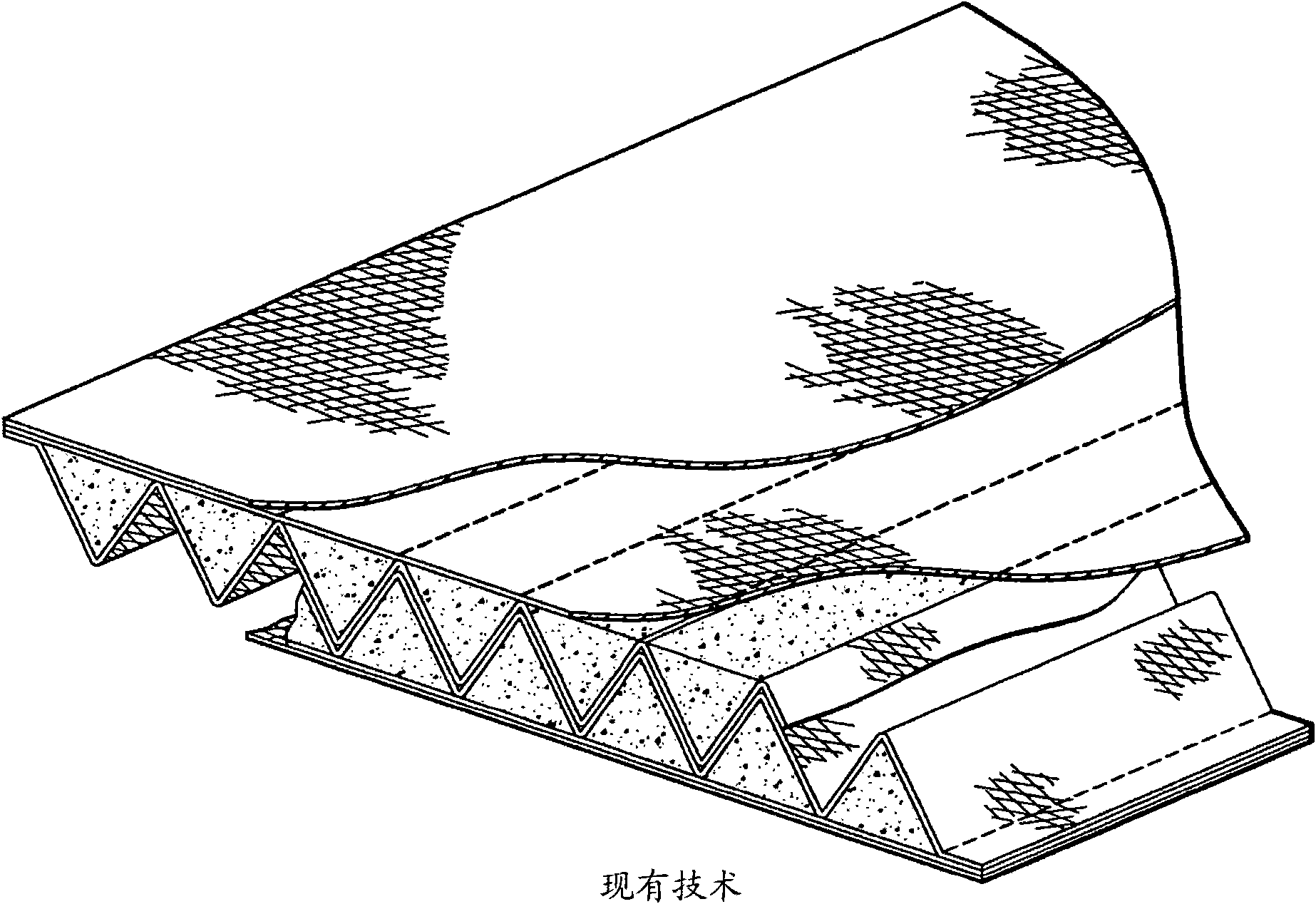

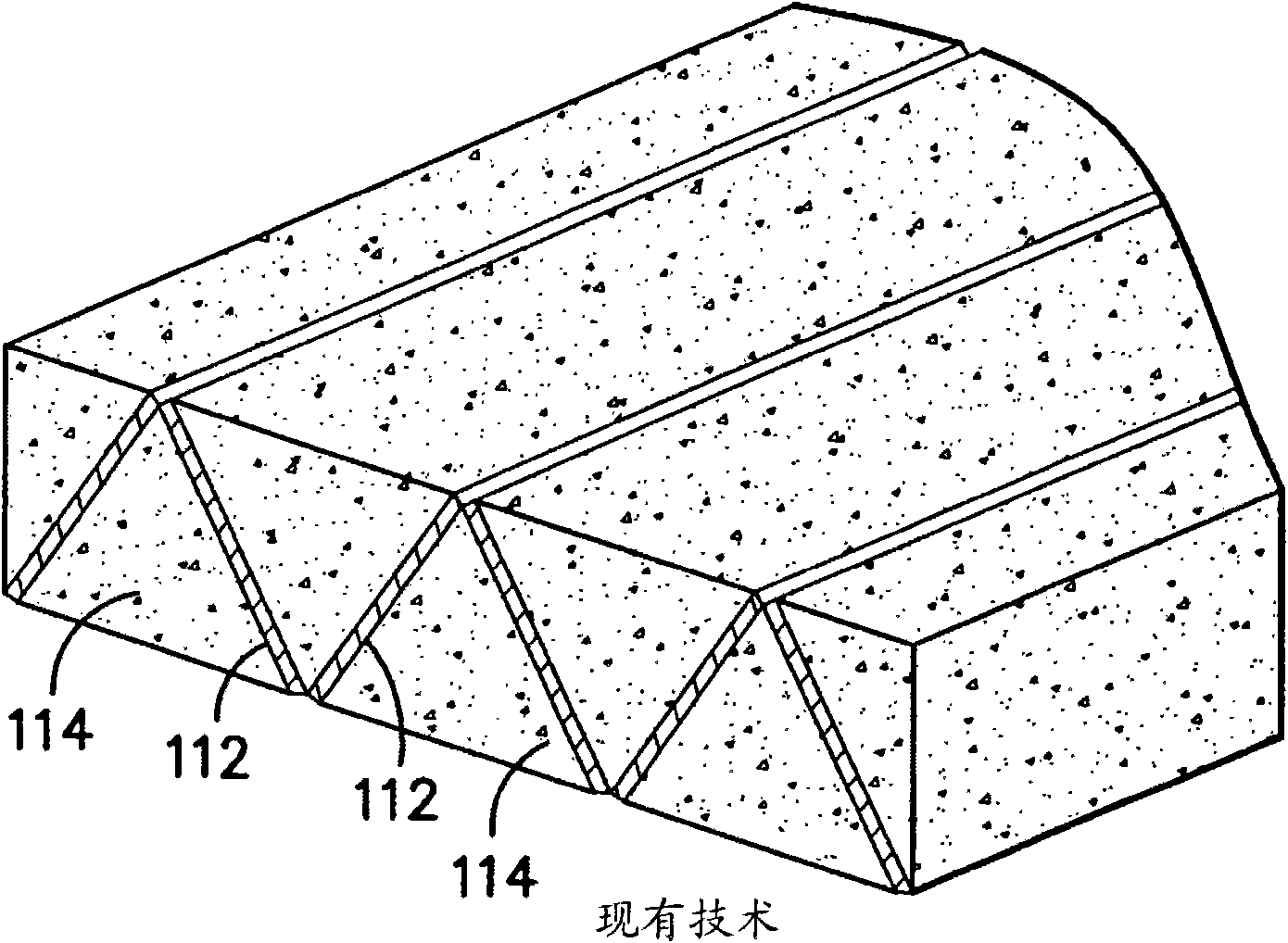

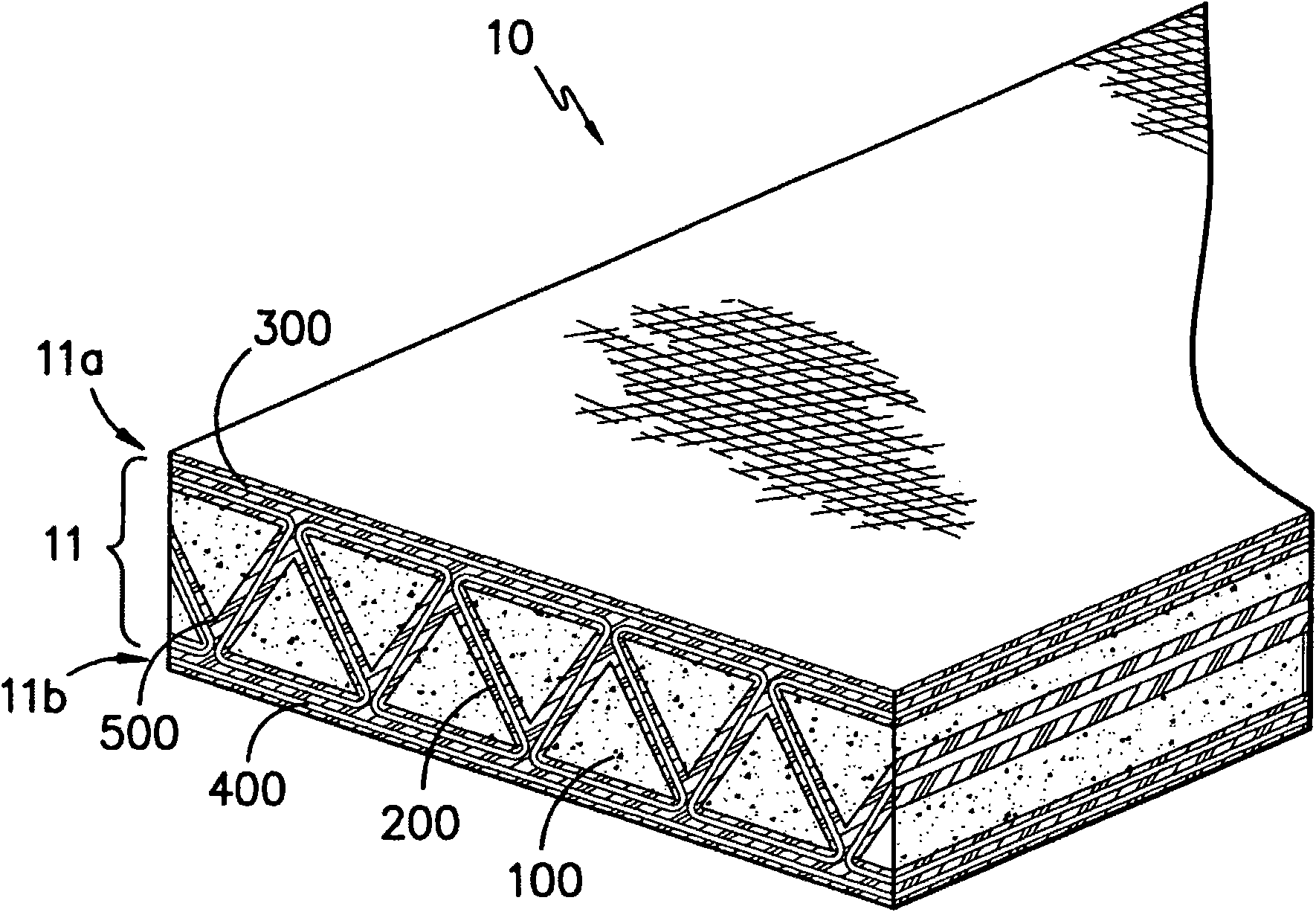

[0020] In contrast to the prior art, in the present invention the winding of the reinforcement sheet around the low density tape creates a situation where it is reinforced by fibers as it progresses between the foam tapes from the surface of the fiber reinforced core panel to the opposite surface of the panel. The corners formed by the sheets form a cross-sectional view that looks similar to the letter Z. As a result, a greater surface area of the foam strip can be covered by the fiber reinforced sheets on the outer surface of the fiber reinforced core panel. The resulting structure not only provides a greater surface area to form a bond between the fiber-reinforced sheets and the outer skin to reduce the possibility of delamination, but also positions more of the fiber-reinforced sheets at the outer surface of the fiber-reinforced core to give the structure Greater strength (as formed by I-beams). Combined with greater coverage of the low density tape surface, this configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com